Two Roll Mill

Lab Two Roll Mill is suitable for mixing and dispersing polymers such as rubber,raw materials of engineering plastics,pigment and masterbatch.

Lab spray dryer capacity has 2L/H, 3L/H, 5L/H, 10L/H,15L/H, which could dry solution and emulsion to powder or granule products directly, don't need evaporation and crushing process. Customization of spray dryer is available.

Manufacturer of bio-reactors (fermenter), bioprocess controllers and bio-engineering services. Its engineering team with experience of designing and manufacturing fermenters devote themselves to studying, improving, and development of fermenters, The products have been widely used in education, scientific research, bio-manufacture etc.,

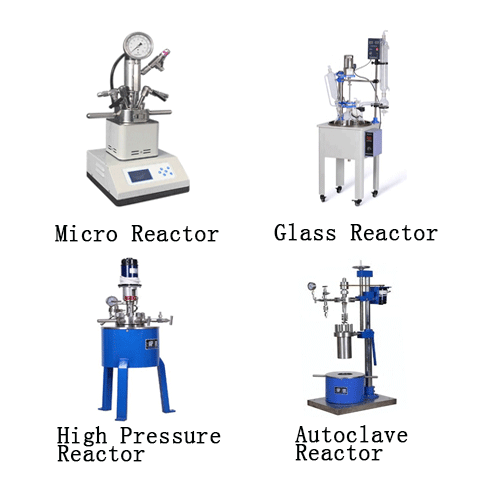

High pressure autoclaves for chemical reactions like hydrogenation, oxidation, alkylation, chlorination. carboxylation, nitration, polymerization, amination, bromination,ethoxylation, esterification, sulphonation etc.

Professional production and sales of food, dairy products, beverages, biological, chemical, pharmaceutical and other fields of the entire line of engineering projects and laboratory equipment.

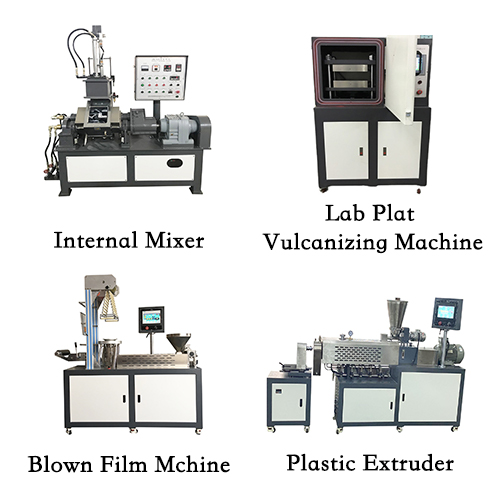

Our main products include: lab single screw extruder, lab twin screw extruder, lab banbury mixer, lab sheet extrusion line,lab cast film machine, lab blown film machine, lab three-roll calender, lab two roll Mill, 3D printer filament extruder.

Co2 dry ice machine with its production capacity is from 50kg/h to more than 1000kg/h. thickness from 10mm to 210mm, Types: pelletizer ,Nugget Ice Machine, Flake Ice Machine.,Free custom

Our main products include: lab single screw extruder, lab twin screw extruder, lab banbury mixer, lab sheet extrusion line,lab cast film machine, lab blown film machine, lab three-roll calender, lab two roll Mill, 3D printer filament extruder.

Manufacturer of bio-reactors (fermenter), bioprocess controllers and bio-engineering services. Its engineering team with experience of designing and manufacturing fermenters devote themselves to studying, improving, and development of fermenters, The products have been widely used in education, scientific research, bio-manufacture etc.,

Laboratory small magnetic stirring glass fermenter for off-site sterilization.

Basic configuration: temperature, speed, PH, dissolved oxygen, defoaming, feeding, tank pressure.

Sterilization-in-place (SIP),equipped with high temperature steam pipeline

The Multifunctional Fluidized Bed Hydrothermal Agitated Tank Reactor

Equipprd with sn easy-to-detach condenser around the air outlet ,for easy cleaning ,no effusion ang no contaminating bacteria

Magnetically Driven(Cell lift impeller Marine Blade impeller pitched blade impeller for option)

Equipprd with sn easy-to-detach condenser around the air outlet ,for easy cleaning ,no effusion ang no contaminating bacteria

Specific Air-distributing ring make liquid and air mix completely,bottom webby forrecycling Enzyme catalysis

Co2 dry ice machine with its production capacity is from 50kg/h to more than 1000kg/h. thickness from 10mm to 210mm, Types: pelletizer ,Nugget Ice Machine, Flake Ice Machine.,Free custom

LN2 LO2 LAr LNG LCO2 Cryogenic Insulated Cylinders: Stainless Steel DPL DPW LIN LOX LAr LNG LCO2 Weld insulated cylinders liquid argon storage tank for sale.

Read More

The dry ice pelletizer can produce dia 3mm to dia 19mm of high strength, particle or columnar, with its production capacity is from 50kg/h to more than 1000kg/h. The dry ice cube making machine can commonly produce ice block in thickness from 10mm to 210mm,. Both of these 2 types machines can be customized according to customer's requirement.

Read More

The core thermal insulation material of the dry ice incubator: polyurethane rigid foam. Our company has obtained technical guidance and support from the Aerospace Group on the formulation of this material.

Read More

Pillow packaging machine is the latest domestic automatic continuous shrink packaging equipment.

Read More

Ice cleaning is applied to the tire industry, rubber casting, automotive, aerospace, machinery manufacturing, mold industry, printing equipment, oil and chemical industry, breaking the traditional time-consuming wash, cut and other shortcomings, efficient, energy-saving and clean, environmentally friendly online new cleaning mode.

Read More

Instantly dry the water-based material into a powder.

Instantly dry the water-based material into a powder.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529