High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

1-3 daysModel Number:

OLT-1Minimum Order Quantity:

1Warranty:

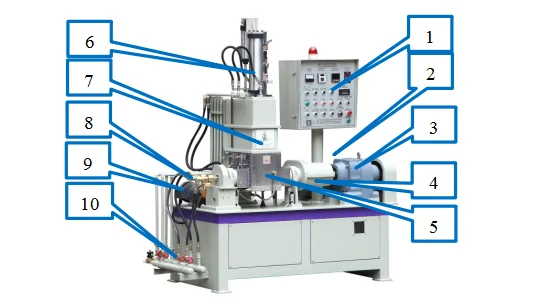

1 yearLaboratory Banbury Rubber Internal Mixer with technical drawings, advanced technology in China and imported core components, this machine has character itself as environmental-friendly, high-efficiency and good dispersing effect, with human-orientated design and easy to reload and clean, it has been recognized by factory lab, universities and R&D institutions for recipe researching and small-scale production. It can also be used in electric wire, cable, electronics, sole, sports equipment and auto parts industries for rubber, plastic and chemical production mixing and plasticizing.

Equipment model and parameters

Driving

Motor

18.5

Air

Compressor

Electricall

Heating

Model

Unit

CF-1

CF-2

CF-3

CF-5

CF-10

CF-15

CF-20

CF-25

CF-35

CF-55

CF-75

CF-110

Capacity

L

1

2

3

5

10

15

20

25

35

55

75

110

KW

3.75

5.5

7.5

11

22

30

37

55

75

110

160

Tilt Motor

KW

0.75

0.75

0.75

0.75

0.75

1

1.5

1.5

2.2

3

4

5.5

Tilt Angle

°

110

110

110

110

110

110

110

110

140

140

140

140

KW

2.2

2.2

2.2

2.2

2.2

5.5

5.5

5.5

5.5

5.5

7.5

7.5

Water Cooling

Mpa

0.2-0.4

0.2-0.4

0.2-0.4

0.2-0.4

0.2-0.4

0.2-0.4

0.2-0.4

0.2-0.4

0.3-0.4

0.3-0.4

0.3-0.4

0.3-0.4

W

700

800

1200

1800

1900

2100

4000

4500

10000

15000

18000

24000

Net weight

KG

800

1000

1300

1500

1800

2800

4500

5000

6500

7800

10800

15000

Detail Image

Why Choose Us

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529