High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

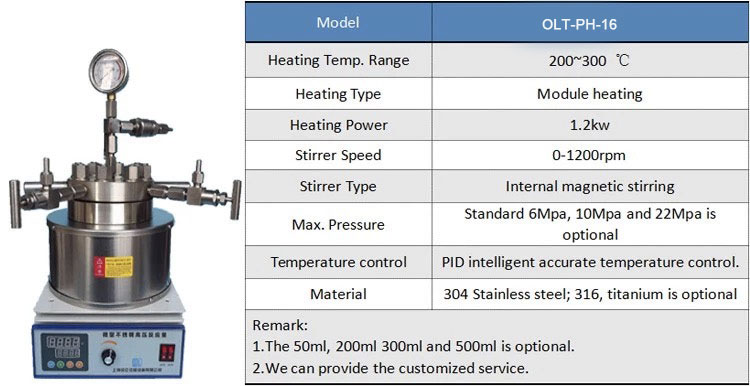

Model Number:

OLT-PH-16Minimum Order Quantity:

1Compliance:

CE CertifiedVoltage:

108V-240VPower(W):

1.2KWCapacity:

50ml-500mlUse pressure:

6MpaService temperature:

200~300 ℃Mixing speed:

0-1200rpmWeight:

30 KGDimension(L*W*H):

450*400*500mmLead Time:

6-8dayWarranty:

1 YearsThe stainless steel reactor suitable used for all flammable and explosive, highly toxic, expensive media and other chemical media penetration with strong stirring reaction. It’s the ideal lab equipment for oil, chemical industry, organic synthesis, polymer polymerization, curing, food etc. in the process of fluoride. no leakage.

1. Small volume perfect, structure is simple and reliable and the accessories are complete.

2. Standard imported mini DC motor, pressure gauge, explosion-proof device, air inlet valve, sampling valve, temperature sensor, can facilitate the realization of micro reaction test.

3. kettle body and the heater can be separated quickly for cooled quickly.

4. Temperature digital display, PID intelligent accurate temperature control.

Miniature stainless steel autoclave is mainly characterized by a static seal structure with static seal instead of dynamic seal, magnetic coupling by stirring and autoclave, non-contact torque transmission completely solves the existing seal directly mixing lax material leakage problems, the medium and the stirring member is completely absolute sealing condition.

The composition of stainless steel reaction vessel:

The composition of stainless steel reaction vessel:

Stirring Model: Internal magnetic stirring, there is no seal leakage and maintenance problems, to ensure no leakage,no bare rotating parts, more safety test

Stirring Motor: Germany imported high power motor, strong and powerful, stable performance.

Inlet gas Valve: Gas inlet needle valve.

Sampling Valve: Easy to sample and analyze the reaction process at any time during the reaction process.

Exhaust Valve: Convenient before reaction on the system of vacuum treatment and replacement of the use of gas,the end of the reaction as a vent valve.

Pressure Gauge: Real time monitoring of pressure in the reactor.

Temperature Probe: Deep inside the reactor body, real-time monitoring of reaction temperature.

Heating Unit: Module heating, heating fast, accurate control, screen digital.

Temperature Control Type: PID intelligent accurate temperature control.

Packing and Shipping

-The main parts will be wrapped with foam,then put into the carton; the mainbody portion will be packed in wooden cases;

-Both neutral and customized packaging can be available.

-We can ship the goods to you by International Express such as DHL,UPS,TNT,EMS and so on, you can also choose the appropriate one based on your timeline and budget. Besides,you can choose to use your own shipping agent

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529