High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Model Number:

OLT-RK-3Minimum Order Quantity:

1Compliance:

CE CertifiedVoltage:

108V-240VPower(W):

60W(Stirring Power)Capacity:

3LService temperature:

RT-250Lead Time:

6-8DayWarranty:

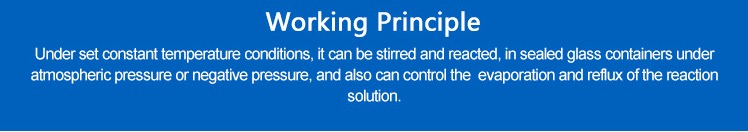

1 YearsGlass Reactor is an equipment which is a collaboration of vacuum state, distillation, reflux, stirring, oil/water heating, heating mantle. It can do all kinds of biochemical reactions and synthesis reactions at a constant temperature condition. It is also a colsed system on the whole.

Circulating water vacuum pump can pump into the reactor sorts of liquids and gases. The reflux or distillation is possible under different temperature state.

The single layer glass reactor has water/oil heating bath or heating mantle itself. Water/oil bath temperature is digital display, which can meet constant temperature state, fast temp. rising, accurate controllers.1-50L is circular and more than 50L is cylinder. After heating we can add the cooling coil in the tank to cool the material in short time.

Model

OLT-RK-01

OLT-RK-2

OLT-RK-3

OLT-RK-5

OLT-RK-10

OLT-RK-20

OLT-RK-30

OLT-RK-50

OLT-RK-100

Voltage(V/Hz)

220 50/60

380 50/60

Stirring Power(W)

60

120

180

Stirring Speed(rmp)

0-1000

60~600

Capacity(L)

1

2

3

5

10

20

30

50

100

Heating Power(kW)

0.5

0.8

1.2

1.5

3

4.5

6

9

Heating Mantle Power (kw)

0.53

0.65

0.73

1.1

2.1

3

3.8

5

......

Temperature Using Range(ºC)

RT-250 | RT-350

Motor Torque(g/cm)

2000

2400

4800

1000

1200

1500

3000

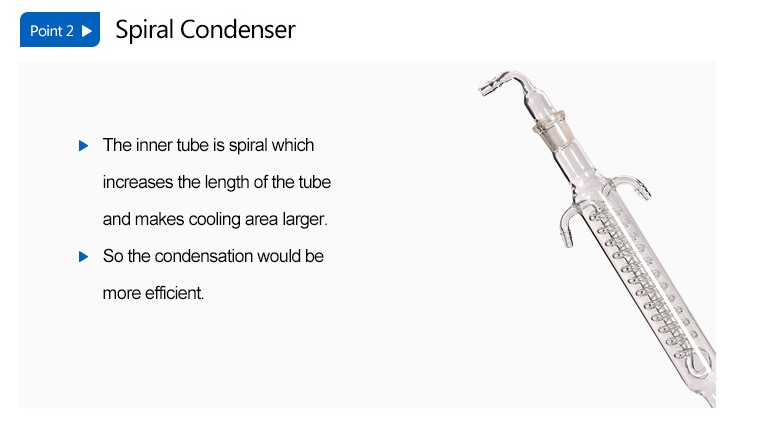

1.High borosilicate glass with nice physical-chemical properties; experiment temperature -100 to 400 degree C; Resistant to strong acidic properties of materials; only touching with glass parts & PTFE, no cross-contamination.

Packaging:

Packaging:

-After use cartons inside, outside with wooden case packaging;

-Both neutral and customized packaging can be available.

Shipping:

-We can ship the goods to you by International Express such as DHL,TNT,EMS,FedEX and so on and you can also choose the appropriate one based on your timeline and budget. Besides, you can definitely choose to use your own shipping agent.

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529