High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Model Number:

OLT-RK-5Minimum Order Quantity:

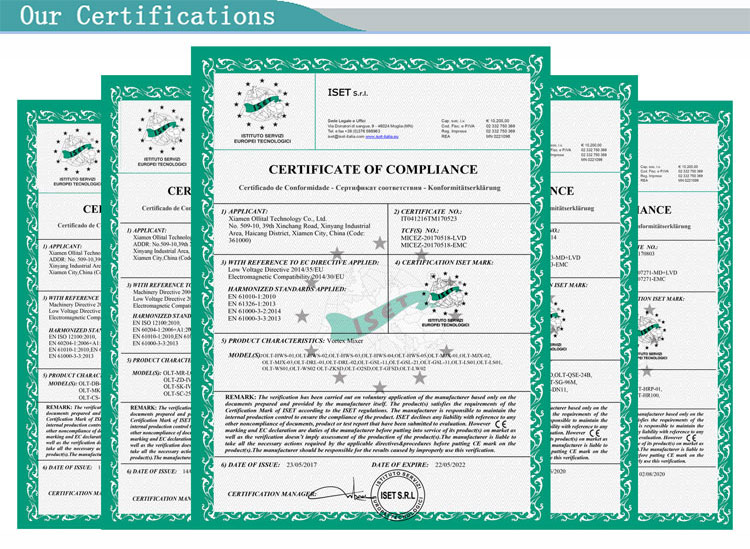

1Compliance:

CE CertifiedVoltage:

108V-240VPower(W):

Stirring Power 60WCapacity:

5LWeight:

40kgDimension(L*W*H):

1330*550*550mmLead Time:

6-8dayWarranty:

Export wooden package

| Model NO. | OLT-RK-5 | Tower Reactor Type | None |

| Heating | Oil Circulation Heating | Heat Transfer Structure | Jacketed |

| Automatic Grade | Automatic | Condition | New |

| Stirring Power(W) | 60W |

Rotating Speed |

0-600rpm(Max.1300) |

| Motor Torque(G/Cm) | 4800g/Cm | Capacity(L) | 5L |

|

Heating Method |

Circulating Water/Oil | Voltage | 108V-240V |

|

Weight |

40kg |

Specification | 1330*550*550mm |

| Transport Package | Wooden Case or as Customer′s Requirements |

Glass Material |

Borosilicate Glass |

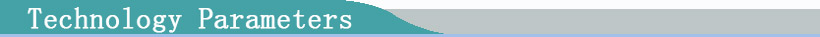

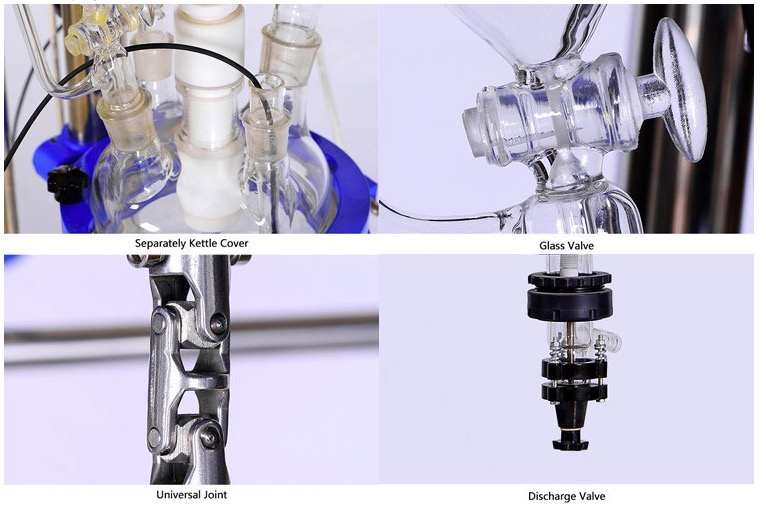

A typical reaction vessel consists of a glass vessel with an agitator and integral heating/cooling system. The borosilicate glass reactor vessel come with sizes from 1L up to 100L. Liquids or solids are feed via connections at the top cover of the reactor. Vapors are discharged through the connections at the top and the wastes are usually discharged out from the bottom.

Production principle:

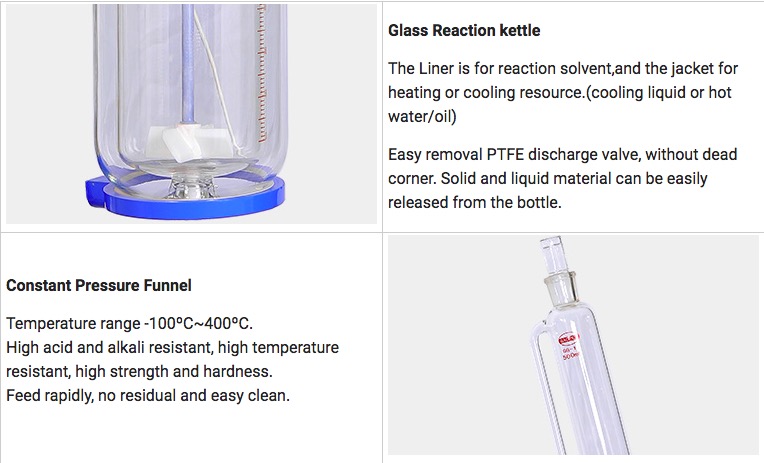

Double-glazed designed glass reactor, the liner is for reaction solvent, and the jacket for heating or cooling resource(cool liquid, hot water or hot oil), to achieve circulating heating or cooling experiment. And its ancillary equipment-High and low temperature machine which can satisfy functional high & low temp reaction experiments.

Ancillary Equipment of Jacketed glass reactor:

1. Circulating water vacuum pump(Desktop type or Vertical type):

2. Low temperature cooling liquid circulating pump (Cooling chiller):

3. Circulating water/oil bath:

4. High and low temperature all-in-one device:

Packing and Shipping

-The main parts will be wrapped with foam,then put into the carton; the mainbody portion will be packed in wooden cases;

-Both neutral and customized packaging can be available.

-We can ship the goods to you by International Express such as DHL,UPS,TNT,EMS and so on, you can also choose the appropriate one based on your timeline and budget. Besides,you can choose to use your own shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529