High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Model Number:

OLT-PR-10Minimum Order Quantity:

1Compliance:

CE CertifiedVoltage:

108V-240VCapacity:

10ml-1000mlUse pressure:

10MpaService temperature:

300℃Dimension(L*W*H):

30cm*40cm*70cmLead Time:

6-8dayWarranty:

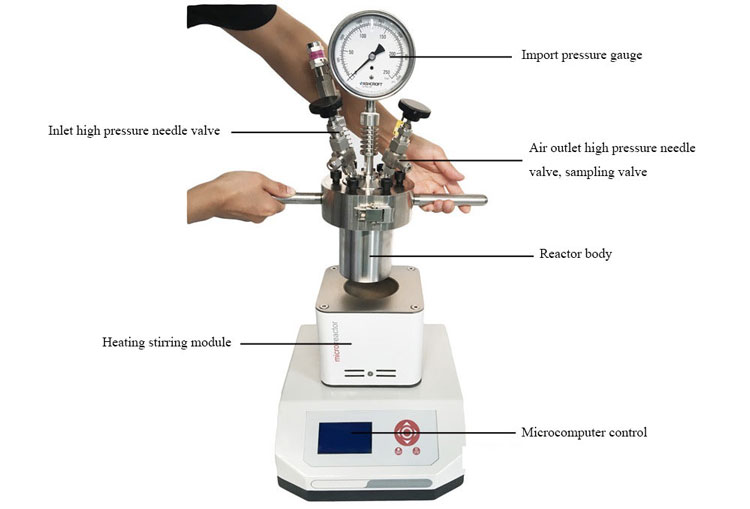

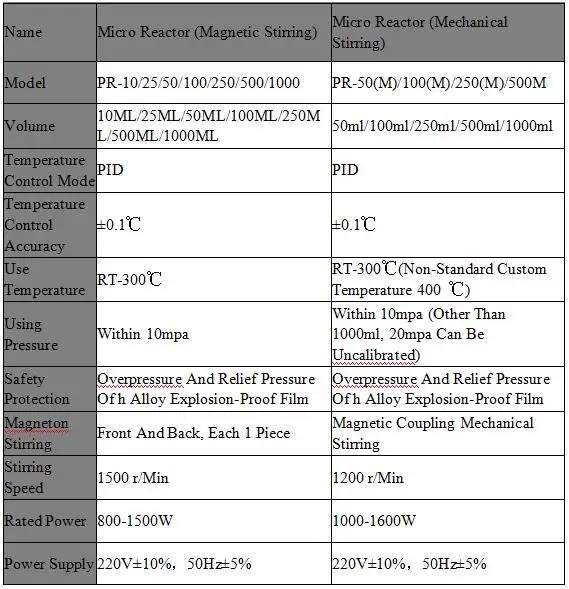

1 YearsMicro reactor has been widely used in chemical, chemical, pharmaceutical, polymer, metallurgy and environmental protection.Such as catalytic hydrogenation, polymerization, hydrometallurgy, esterification, spices synthesis, supercritical reaction.

![]()

1.Appearance: the chassis shape adopts mold integration molding, the surface electrostatic spraying plastics is not only beautiful and generous and anti-corrosion and anti-static, but also makes the first line of defense for our safety experiment.

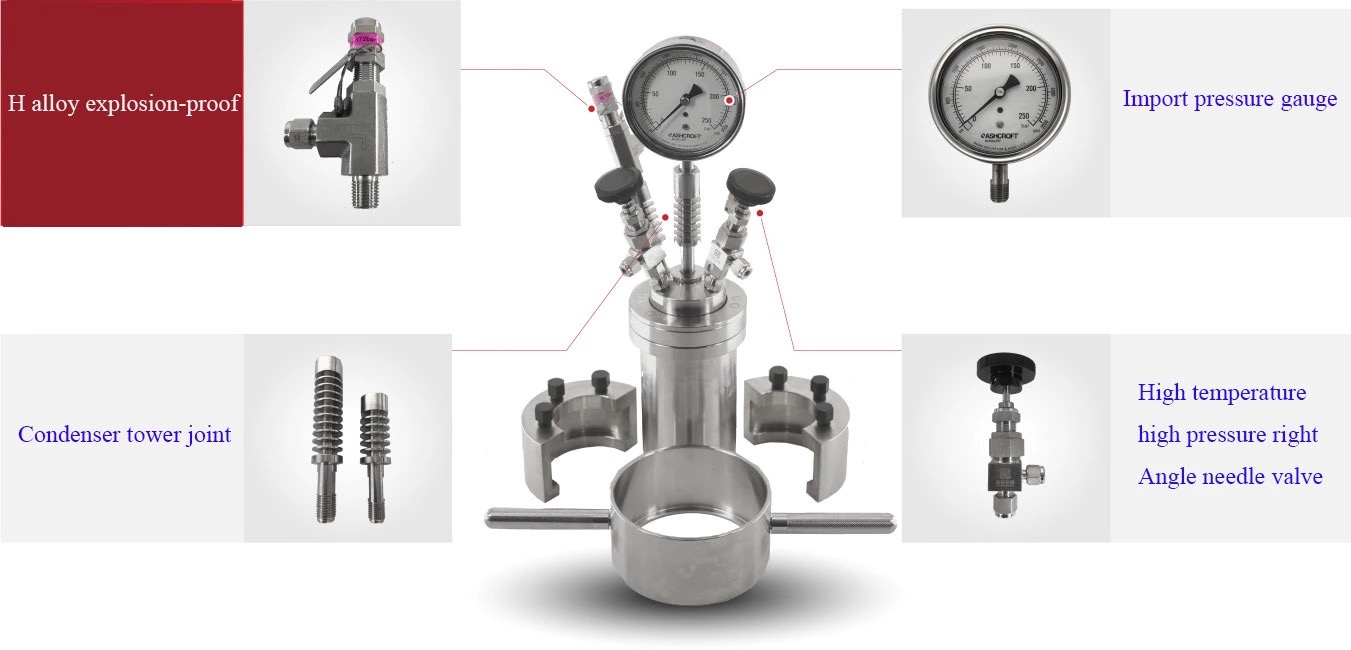

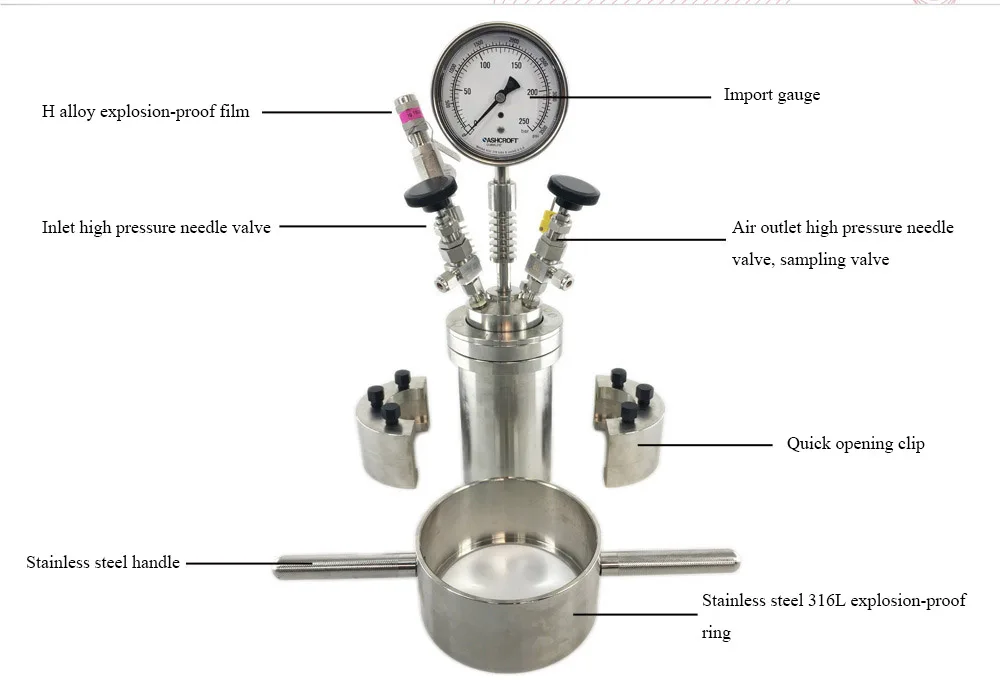

2.High quality imported accessories: original German wika radial pressure gauge, American omega k temperature sensor, harth alloy explosion-proof film and other high-quality imported accessories make a second line of defense for our safety experiment;

3.Patent type heating module: embedded stainless steel heating module is the first heating mode applied in micro counter, heating efficiency is the common aluminum heating, heating furnace heating, electric heating set of 1.5-2 times, life to three times higher than common modules and strong and beautiful deformation more on different parts of the residue for reaction kettle heating efficiency and the escort service life;

4.Complete material selection: standard quality T316SS stainless steel (316), also loyal 400 (monel 400), loyal 600 (Alloy600), Alloy C276 (harth Alloy C276), Alloy b-3 (harth Alloy b-3), Titanium (Titanium) and other quality metals are available;

5.Precise intelligent Controller: the mr-controller is specially designed for micro-reactor series.

(1)Accurate temperature control: the precision can reach 1 effective digit after the decimal point;

(2)Support self-setting function: temperature self-setting can be carried out according to different operating temperatures;

(3)Timing function: you can control the timing between 1-9999 minutes according to different conditions of use;

(4)Positive and negative rotation: the motor can be controlled to alternately rotate and stir forward and reverse;

(5)Digital display function: the speed, temperature and time can be digital display.

6.Complete standard configuration: gas injection valve, gas release valve, liquid sampling valve, probe bottom tube, pressure gauge, temperature sensor, explosion-proof film, high-temperature magneton, this configuration can meet the response requirements of most chemical processes.

Configuration list:

|

No. |

Name |

Quantity |

Note |

|

1 |

Heating Stirring Control Base |

1 |

MR - Controller |

|

2 |

Flange Body |

1 |

316 L |

|

3 |

Imported Wika Pressure Gauge (0-16mpa) |

1 |

Germany |

|

4 |

Explosion-Proof Film (Haversian Alloy),12.5mpa |

1 |

C276 |

|

5 |

Gas Sampling Valve |

1 |

|

|

6 |

Gas Release Valve |

1 |

|

|

7 |

Omega Thermocouple For Temperature Measurement |

1 |

United States |

|

8 |

Extension Cord Of Thermocouple |

1 |

United States |

|

9 |

Thermocouple Sleeves |

1 |

316 L Material |

|

10 |

Dip Tube |

1 |

316 L Material |

|

11 |

Inlet Plate Sealing Ring |

1 |

United States |

|

12 |

Teflon Lining |

1 |

Four Fluorine |

|

13 |

Quartz Glass Lining |

1 |

Quartz |

|

14 |

Magneton |

2 |

|

|

15 |

Special Tool Wrench |

1 |

|

|

16 |

Fuse |

2 |

|

|

17 |

Instruction Manual, Certificate, Warranty Card, Packing List |

1 |

Packing and Shipping

-The main parts will be wrapped with foam,then put into the carton; the mainbody portion will be packed in wooden cases;

-Both neutral and customized packaging can be available.

-We can ship the goods to you by International Express such as DHL,UPS,TNT,EMS and so on, you can also choose the appropriate one based on your timeline and budget. Besides,you can choose to use your own shipping agent

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529