Product Description

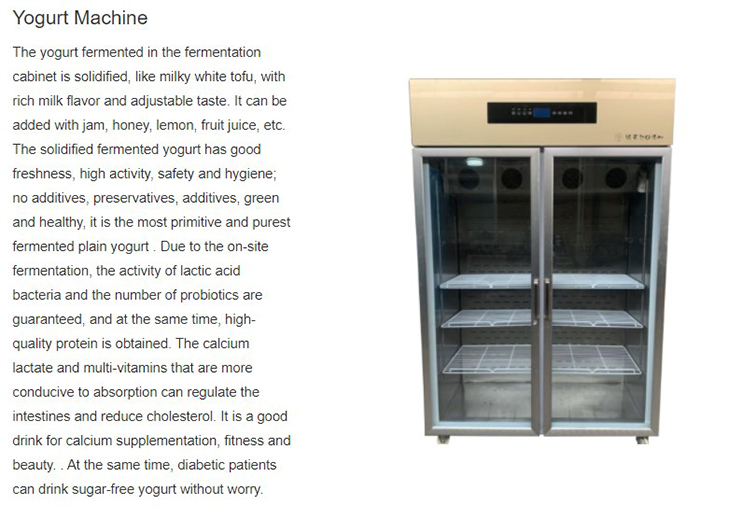

Yogurt is a sweet and sour milk drink. It is a milk product that uses milk as a raw material. After pasteurization, beneficial bacteria (leavers) are added to the milk. After fermentation, it is cooled and filled. Most yogurt products on the market are solidified, stirred, and fruity with various fruit juices and jams.

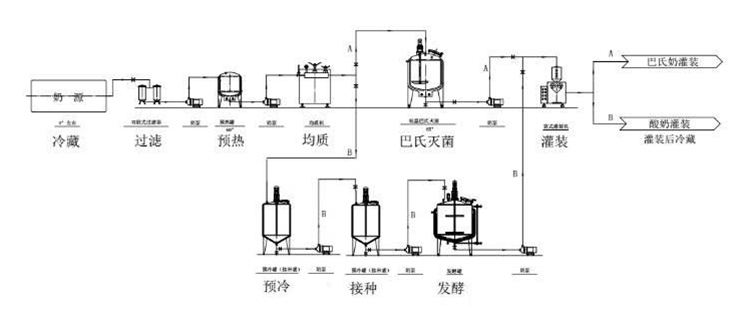

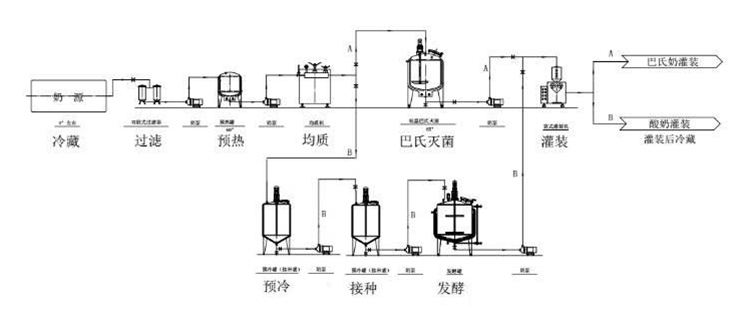

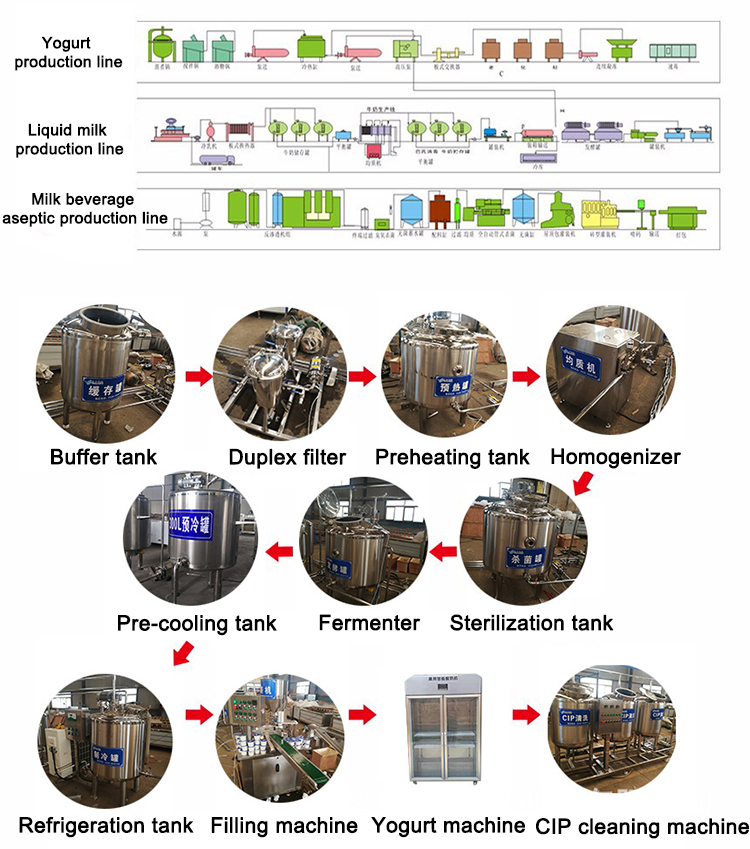

Process: Raw milk → Filtration → Preheating → Homogenization → Stirring sterilization → Fermentation → Refrigeration → Filling.

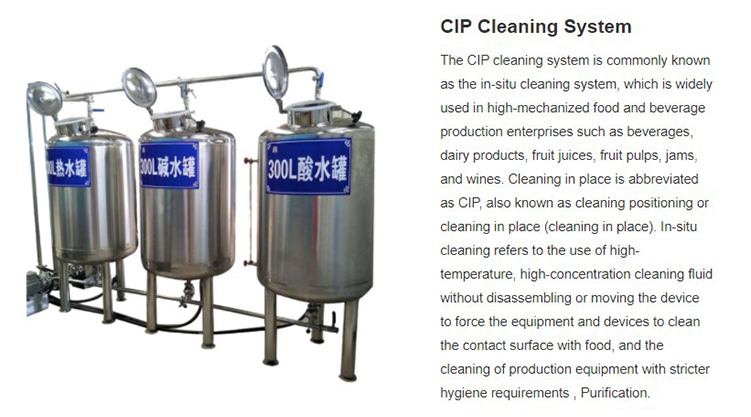

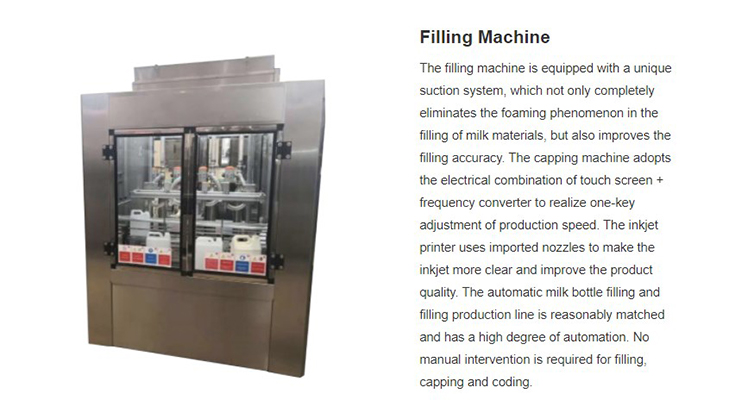

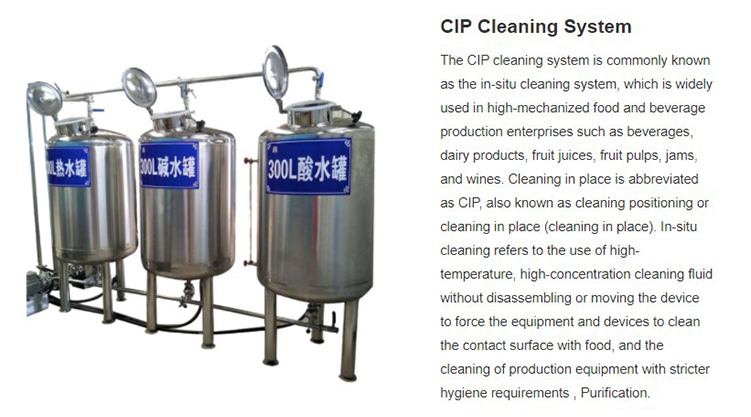

Matching equipment: Raw milk → Pump → Filter → Pump → Preheat tank → Pump → Homogenizer → Pump → Whisk tank → Pump →Fermenter→Pump → Refrigeration tank → CIP cleaning system.

Product Details

Finished Yogurt

Yogurt is fermented milk produced by lactic acid bacteria. The national standard allows fermented milk to use additives, which is required by the production process. Additives are used in reasonable limits and will not harm human health. So, don’t worry too much about yogurt containing additives. Homemade yogurt can be made without additives. However, this does not mean that homemade yogurt will be safer.

Features

Semi-automatic or fully automatic

Customized design

Automatic CIP clean

Sanitary material, no dead angle

High efficiency

Yogurt production line display

Packing & shipping

Company & Profile

Xiamen OLLIITAL Machine Co., Ltd. is specialized in the research, production, sales and services of high precision automatic roll to roll screen printing machine, roll to roll heat press machine, intermittent letterpress printing machine, tunnel dryer, automatic feeding machine, automatic receiving machine, automatic cutting machine, die cutting machine, automatic web-guide rewinding machine and printing-related supporting equipment. We can develop machine according to customer needs and provide one-stop service for ink, glue, printing materials, printing technology, etc.CRTOP screen printing machine is widely used for high precision and automatic printing of heat transfer labels, nameplate, membrane switch, FPC, RFID, IMD. The machine features an automatic register system to ensure high printing accuracy. It can realize automatic feeding, automatic printing, automatic drying and automatic rewinding. One operator can complete the entire production process. Our machine can meet customers' needs to improve efficiency, reduce manpower, improve yield, reduce cost, and help customers realize the transformation from manual or semi-automatic production to automatic production.Lingtie continuously innovating technology and improve machine performance. Our high-precision, high-end, and durable printing equipment has earned us good reputation in the industry and sold to more than 30 countries worldwide. With the continuous increase in labor management cost and land cost, automatic equipment is sure to replace semi automatic or manual production in the future. This is the trend of social development. In the face of opportunities and challenges, Lingtie will keep to its original goals and continue to go ahead.

FQA

1, Are you trading company or manufacturer?

We are manufacturer, and also provide the business solution to all the friends.

2, Do you have quality certificate?

Yes we have CE, SGS etc.

3,What's the delivery time?

Around 20~30days, however, based on order.

4, Can you help us to buy other goods? Sure of that, it is our honor to work for you, and control the goods quality.

Q1:what's payment terms ,trade terms you accept ?

Usually we appreciate T/T 30% deposit , then 70% balance is paid before shipment .but we also accept other way like L/C , we tern union ,and do CFR&CIF etc.

Q2.Does it easy to operate and what can i do if it doesn't work?

First ,our machine is stable and easy to operate by one man ,what you do is just learn some basic thing like loading the jumbo roll paper,start the machine and cutting the paper.And we will sent you manual and video ,we suggest you to come to visit our factory to learn more thing by yourself , and if there is something goes wrong , you can call us ,video-chat ,email us .And we will give solutions within 36 hrs .Our engineer also can be distributed to overseas as you required.

Q3. if the machine's spare parts broken ,where can i get ?

We will give you the spare parts which is vulnerable , and some critical parts like gear box , our quality is good .

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529