High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Item NO.:

SDHB-3Lead Time:

7daysShipping Port:

XiaMenWorking Principle

Based on big power inverter technology (AC-DC-AC-DC),we could convert the input current into the DC power of low voltage and high current ,which is what we need for welding.

By using microcomputer technology,our could :

1)get precise control of welding time

2)make the electric energy act between tungsten electrode and workpiece, in the form of pulsed ARC

3)extremely high temperature ARC make solder wire and the workpiece(made of metal material)melt together

4)thus welding task completed

Technical Superiority

1)very fast heating speed and little heat when welding:our machine could finish the soldering of workpiece and solder wire in several milliseconds

2)to the base of workpiece ,the less heat, the less warming up for the material except for the welding spot thus no color change and annealing effect happen

3)because of the extremely concentration of output pulse energy,our machine could weld copper and aluminum,which is hard for many many welders

4)high strength of welding,applied to metallurgy welding.the welding area after welding could be done with after-treatment such as milling and filing

5)reasonable power allocation,controlled by microcomputer chip,different workpiece could get perfect power allocation

6)large range of adaptation for voltage:when voltage is changing in 20%,machine could still provide steady power to be working normally

7)convenient to connect to the electricity:equipmented with Quick connector connector

8)easy to carry:light and small

Technology Parameters

Machine model

SDHB-3

Input Power

AC220V 50/60HZ

Power

0-4000W

Max Pw

40kw

Output

1-200A

Frequency

1-10HZ

Welding model

spot welding/continuous welding/arc welding /electro welding

Range of welding wire

0.3-2.0mm

Weight

9kg

Size

370*155*320mm

Advantages

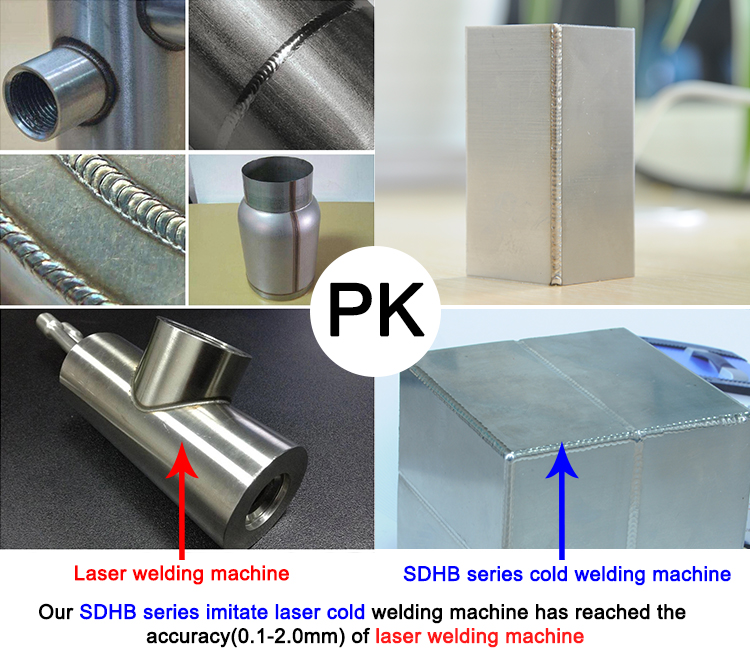

Welding precision:Our SDHB series imitate laser cold welding machine has reached the accuracy(0.1-2.0mm) of laser welding machine

Price:Our cold welding machine is far cheaper than laser welding machine

Welding operation:Our cold welding machine is easier to operate than laser welding machine.You don't need to waste time to learn professional welding skills or employ a welder

Welding functions:Our cold welding machine has more functions (spot/continuous/arc/resistance welding)

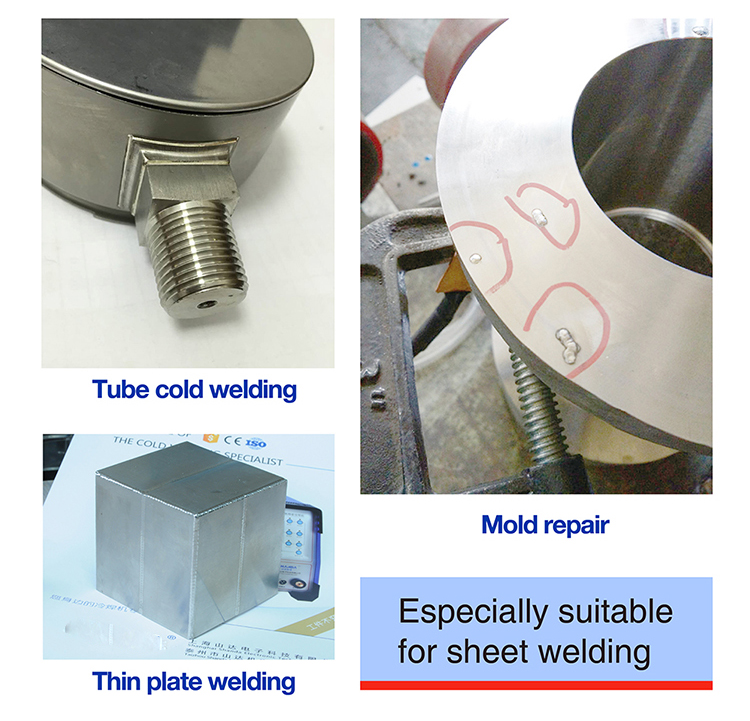

Application&Samples

Excellent heat control,no damage to the workpiece.

Complete metallurgical wld,later under a variety of processing.

Can be used with all types of fillers,dia.0.2mm-1.6mm.

Apply to all kinds of molds,dies,press dies,stainless parts,cast iron parts,aluminum parts,copper/brass/bronze parts.

Recommended Products

|

Machine Model |

SDHB-2 |

SDHB-5 |

|

Input Power |

AC220V 50HZ |

AC220V 50HZ |

|

Power |

0-4000W |

10-1600W |

|

Max Pw |

40KW |

>40KW |

|

Output |

1-200A |

1-500A |

|

Frequency |

1-10HZ |

1-5HZ |

|

Welding Mode |

Spot/continuous/arc welding |

Spot/continuous/resisitance welding |

|

Range of Welding Wire |

0.3-2.0mm |

0.1-2.0mm |

|

Weight |

9kg |

15.75kg |

|

Size |

370*155*320mm |

185*440*320mm |

|

Feature |

Precision repair sheet welding machine |

Color plate welding without discoloration on the back |

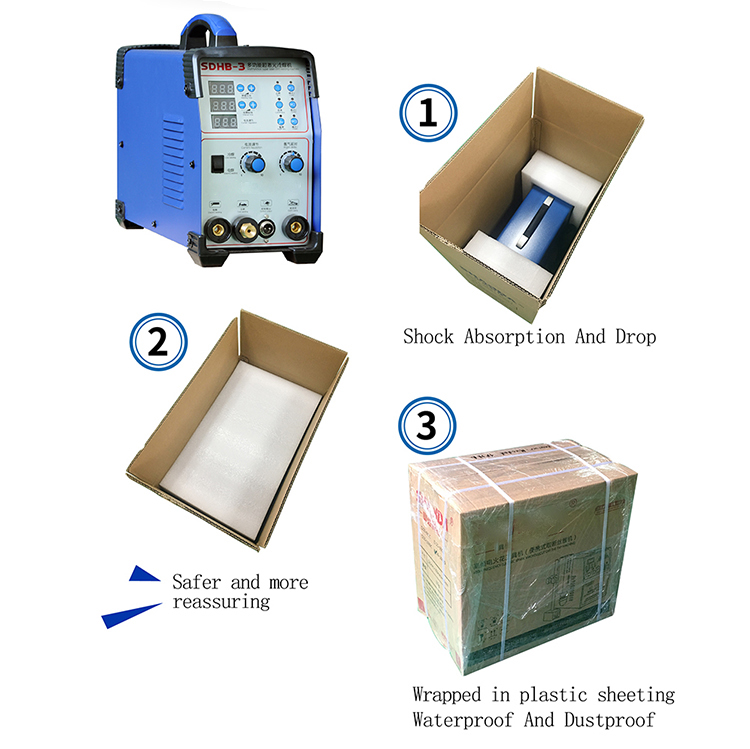

Packing Details

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529