High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Item NO.:

HS-BDS07Q3Lead Time:

7daysShipping Port:

XiaMenProduct Description

Application

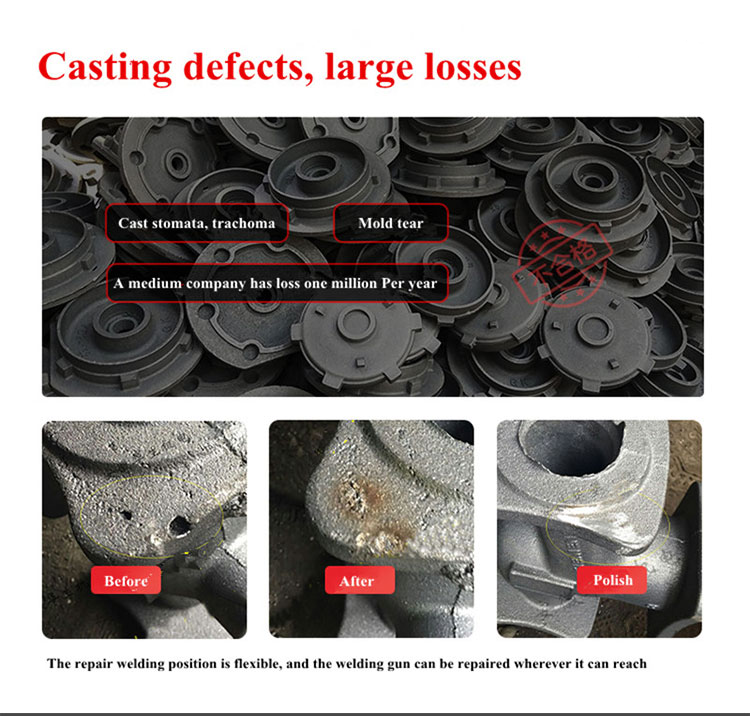

Auto parts casting products:

Repair of casting defects such as crankshafts, pistons, cylinders, intake and exhaust pipes, brake discs, such as sand holes and air holes.

Machinery industry and machine tool industry:

Correcting out-of-tolerance or worn workpieces, such as repairing machine tool guides, bed, shafts, tooth parts of large machinery, cold and hot rolls for steel rolling, hydraulic rods of construction machinery, printing machine cylinders and other various parts Welding.

Aviation and shipbuilding:

Compressor shell, air compressor shell, stainless steel precision parts, precision shafts, etc. Product repair in petrochemical, coal, engineering machinery and many other industries.Non-ferrous metal parts in various industries, such as aluminum alloy parts of SF6 transformers in the power industry, aluminum alloy cylinder blocks, cylinder heads, wheels in the automotive industry, fan aluminum alloy impellers, aluminum alloy radiators, etc.Copper alloy plumbing valves, fittings, etc.

Injection mold:

Welding repair of mold wear, bruises, scratches, etc. to eliminate flash and burrs of products.

Die-casting mold:

The etch marks, shedding, damage, etc. of the zinc-aluminum die-casting mold, as well as the surface strengthening of the cavity and the sprue gate, extend the service life of the mold.

Model

HS-BDS07

Voltage

20-100v

Device frequency

50-500HZ

Torch speed

1-20

Device power

3800W

Input current

AC 220V

Output percentage

20-160%

Machine Size

405x210x450MM

Machine Weight

22.5KG

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529