High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Overview:

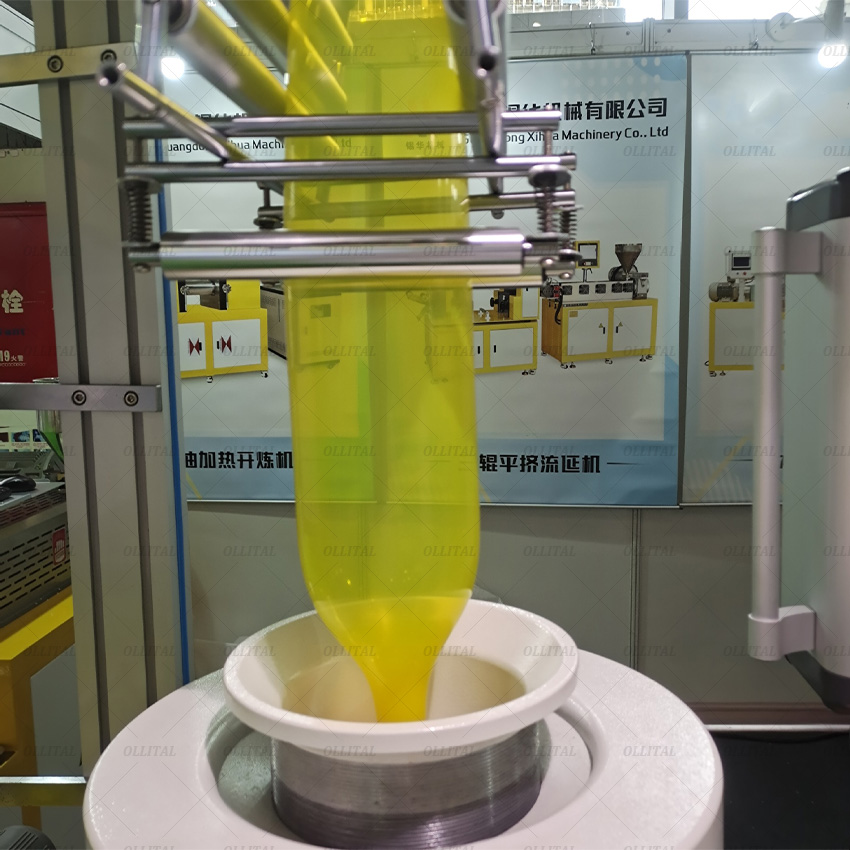

Extrusion blown film refers to the double-fold plastic film obtained by continuously extruding the plastic melt through the die under the action of a certain temperature and a certain shearing force,which is inflated by compressed air,cooled by an air ring,and traction by frequency conversion. crafting process. This machine is mainly used to detect the feasibility of blown film of polymer materials and the colloidal condition in the material,as well as the dispersion of colored dispersions,control mixtures,and extrudates.

Working Principle

1. Heating and melting of plastic particles: Plastic particles enter the extruder through the hopper, and after heating and screw rotation extrusion, they gradually melt into a viscous flow state.

2. Extrusion molding: The molten plastic is extruded through the die head to form a tubular film (called "film bubble").

3. Blowing molding: The film bubble is blown up by compressed air to form the required film thickness and width.

4. Cooling and shaping: The blown film bubble is cooled by the air ring and gradually solidified.

5. Traction and winding: The film is stretched by the traction roller and finally rolled into a coil by the winding device.

Control processing system:

The machine adopts advanced automatic control system-PLC programmable control system as the electrical control system. The control device based on the combination of integrated circuit and electronic technology and 3C technology is applied to electrical control by programmed means. It has the characteristics of strong versatility,easy use,wide adaptability,high reliability,strong anti-interference ability,and simple programming. . Compared with the ordinary relay control system,not only the performance and the degree of automation are greatly improved; and the failure rate is much lower than that of the ordinary relay control system. The PLC control system of the equipment adopts the latest CPU module from Germany SIEMENS.

Compared with the previous generation CPU module,the operation speed is 40% faster. It has online program editing function,PID self-tuning command,linear ramp pulse command,CPU diagnostic LED.

Main features:

ØBuilt-in analog I/O (2 analog input,1 analog output)

ØBuilt-in 14 inputs/10 outputs,a total of 24 digital I/O points

Ø2 RS485 communication/programming ports,with PPI communication protocol,MPI communication protocol and free way communication capabilities

Ø20K bytes of program and data storage space

Ø2 high-speed pulse outputs of 100KHz

Ø6 independent high-speed counters (100KHz),TTL~24VDC high-speed counting,sink or source pulse output

ØControl system: Siemens PLC (using Siemens touch screen for working status control,data acquisition,calculation processing and other projects.

ØIts functions include: all automated program control)

ØFriendly operation interface: touch screen + buttons

ØFast system startup time and operation response time

ØLarge storage space

ØTouch sound feedback

ØComprehensively updated hardware design,unparalleled high reliability

ØMultiple online language switching,so that your device can be used all over the world

ØUsing 32-bit ARM7 processor,excellent performance Integrated LCD controller

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529