Product Description

Industrial small complete fruit juice making processing production line / apple juice hot filling capping machine equipment

Features:

Juice Filling Machine is mainly designed for filling hot temperature liquid.

For example juice, tea drinks etc which are made of concentrate juice.

The final filling temperature will be around 85-90 degree centigrade.

Once the thermal meter in juice filling machine is lower than the temperature, juice will be return to sterilizing machine again through return system.

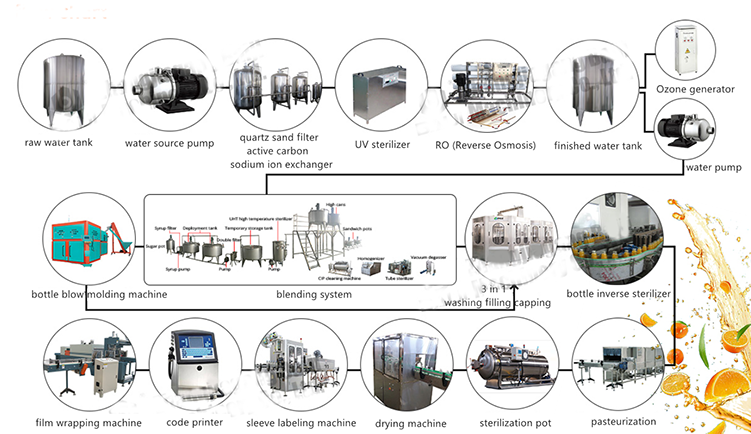

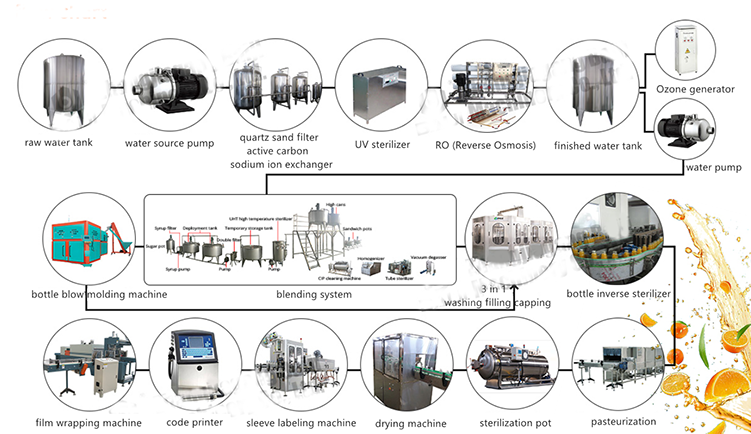

Water treatment system

Processing included: quartz sand filter, active carbon filter, sodium ion exchanger, precision filter, RO (Reverse Osmosis), UV sterilizer, finished water tank

Juice blending system

Concentrated fruit juice → Syrup melting pot→ Beverage pump → Syrup filter → Blending tank → Beverage pump→Double head filter →Juice Homogenizer → Beverage pump → Vacuum degasser→ Screw pump → Beverage tank→ Beverage pump → Super high temperature sterilizer(UHT) → Heat insulation tank → CIP system

Automatic bottle blowing machine

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the pure water bottle, mineral water bottle, carbonated drink bottle, juice hot fill bottle and oil bottle etc.

Inverted bottle sterilization machine

Inverted bottle sterilizing machine could overturn bottles(sterilizer glass bottle or PET bottle), which have been filled and sealed, to sterilize inside of bottle mouth and caps by high temperature drink in bottle.

Pasteurization

This machine is usually used after fruit juice beverage finished hot filling and sealing, when enter the spray tunnel, the water with the function of high-pressure pump, uniformly spray on the bottle body. The bottles move slowly in the chain, when they are out the tunnel, they can reach the normal temperature, then achieve the purpose of cooling. This machine can also be used for secondary sterilization for fruit juice.

Automatic labeling machine

The auto shrink sleeve labeling machine consist of auto labeling machine, heat shrink tunnel and steam generator.

This mahcine adopts international advanced technology,cover the circle label on the pet bottle.And then hot shrinking to fix on the position which bottle body designated.

Automatic packaging machine

PE film shrink wrapping machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529