High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Item NO.:

LK-SW-200WLead Time:

7daysShipping Port:

XiaMen

Technical Parameters

|

Model |

LK-SW100 |

LK-SW200 |

|

Laser output power |

100W |

200W |

|

Laser type |

YAG pulse |

|

|

Laser wavelength |

1064um |

|

|

Pulse width |

0.1ms-20ms |

|

|

Pulse energy |

120J |

150J |

|

Pulse frequency |

0-50Hz |

|

Size of welding spot |

0.2mm-2.0mm |

|

Adjusting range of light spot |

1.8mm |

|

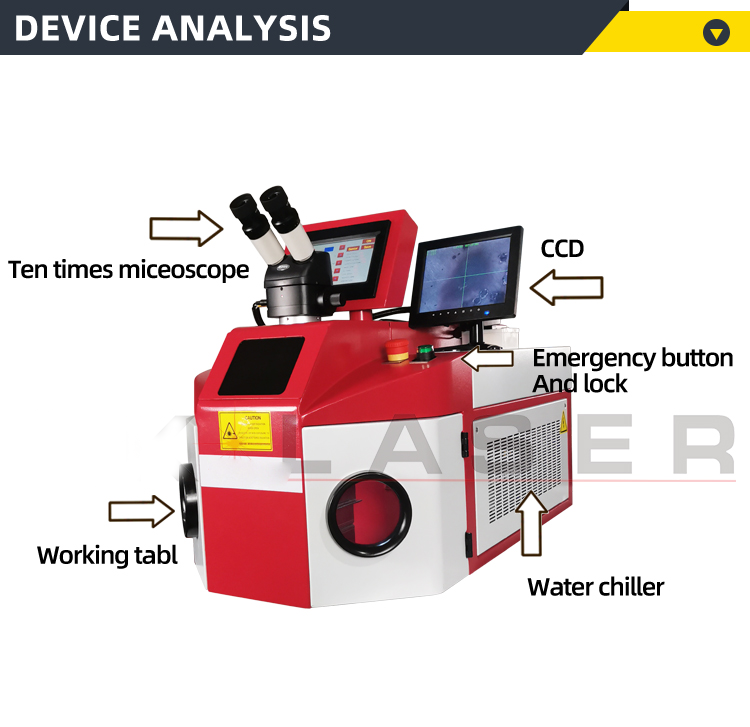

Max. bearing of work bench |

25KG |

|

Repeating precision of work bench |

-0.001 |

|

Positioning precision of work bench |

-0.001 |

|

Sighting positioning system |

HD-CCD monitor system |

|

Cooling method |

Water cooling |

|

Max. output power |

200W |

|

Integrity power |

5KW |

|

Power supply |

AC220VAC/380VAC+-15%/50HZ/25A |

|

Guarantee |

1 year |

|

Dimension |

840mm * 450mm * 500mm |

Master unit 1000×580×1080mm

Cooling system 400×350×880mm

|

|

Net weight |

50KG |

120KG |

1) One key operation: one key switch, simplify the starting process , convenient use process Cumbersome Process.

2) The single chip microcomputer control regulation: the storage 50 groups commonly used welder parameters, convenient use again.

3) The energy, pulse width, frequency and light spot size can be adjusted in a large range to realize different welding effects. The parameters are adjusted by the lever in the seal cavity, which is simple and highly efficient.

4) Use the most advanced light shielding system to eliminate the irritation to eyes by light during working.

5) Able to work for 24 hours continuously; stable performance; free of maintenance in 10,000 hours.

6) Human-based design accords with ergonomics, avoiding fatigue after long time working.

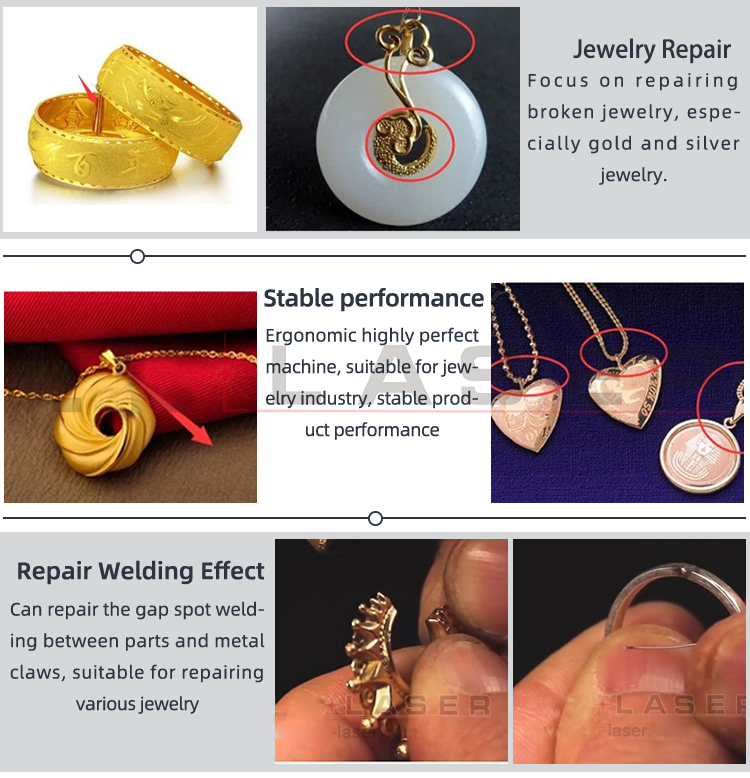

Application Jewelry act the role of tasted fill holes, spot welder seam lines and sand holes, repair set foot part welder parts claw. Can also be used to fill sand holes and small teeth precision components such as batteries with nickel, integrated circuit leads, watches and clocks, kind, austenitic stainless in the fields of electron gun, assembly welder.

Widely used in aviation, aerospace, sports products, jewelry, golf head, medical instrument, titanium alloy denture, instrument, electronics, machinery, automobile, etc, especially for the perforating of gold and silver jewelry, spot welding, repairing, inlay and welding of claw.

The welder process of heat affected zone is small Welding spot size can be adjusted freely. Solder fine, smooth, beautiful, without too much welder post-treatment. Accurate positioning Welding speed, high quality, and high efficiency environmental pollution, the solder joints. Applicable gold, silver, platinum, stainless steel, titanium and so on many kinds of metal and alloy.

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529