High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

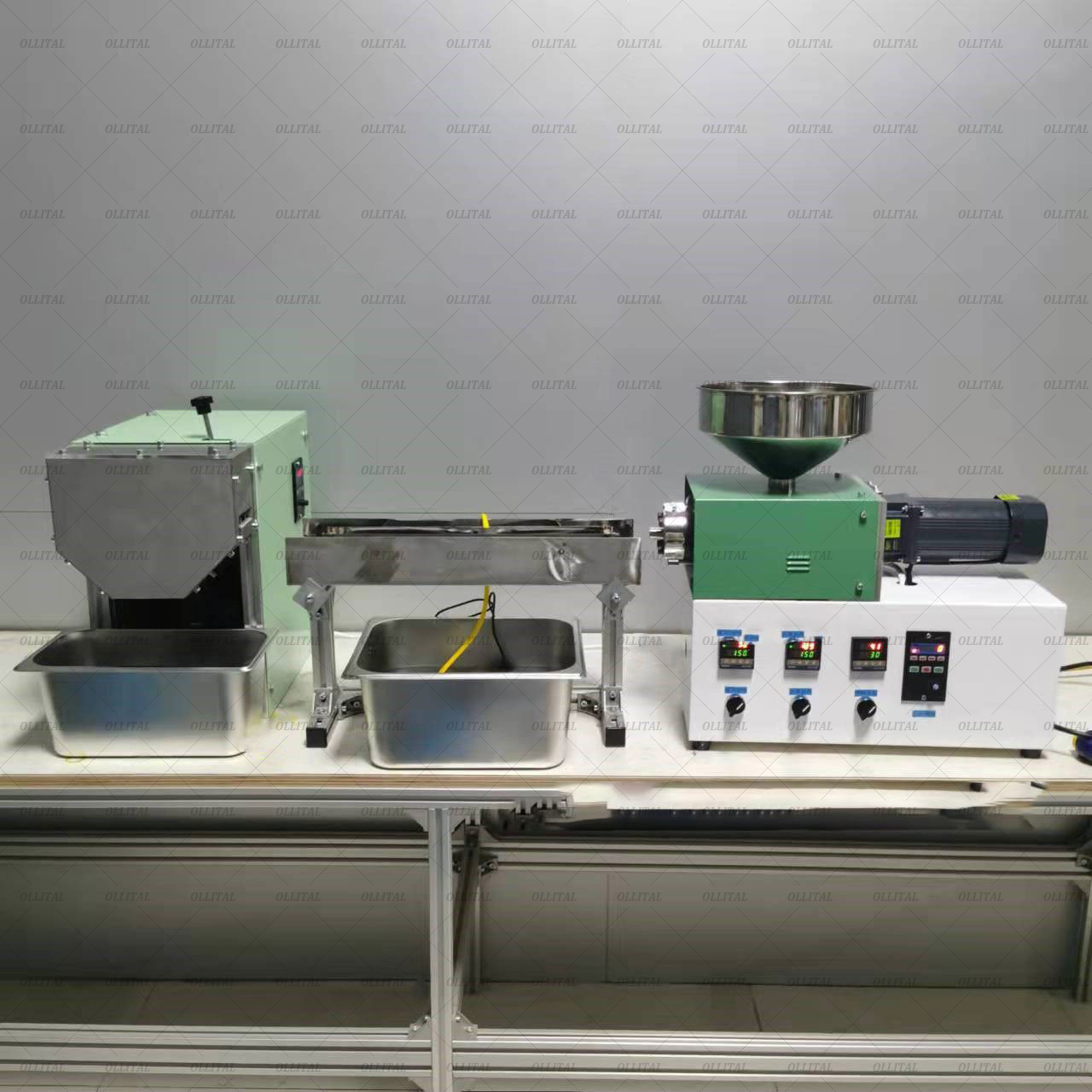

Working Principle

-Material conveying: The material enters the barrel from the feeding port, and under the rotation and push of the two intermeshing screws, it rolls forward along the screw groove and is initially mixed in the complex area formed at the screw meshing point.

-Heating and melting: The heating system inside the barrel heats up the barrel to help soften the material, while the rotation and shearing action of the screw further accelerate its melting process.

-Mixing and plasticizing: The special structural design of the screw makes the material experience different pressure and temperature changes during the conveying process, and various modified additives are evenly dispersed in the material to achieve better mixing and plasticizing effects.

-Extrusion molding: The material is gradually pushed to the die head, where it is subjected to high pressure and shear force, and is extruded into strips or sheets of specific shapes.

- Cooling and pelletizing: The extrudate is solidified after being cooled by air or water, and then cut into granular products by a pelletizer.

Structural composition

- Gearbox: The reduction and torque distribution parts are integrated into one, with a compact structure. It uses needle bearings and high-quality alloy gears with high precision, high strength and low noise.

- Screw: It is a building block structure. The core shaft material is mostly 40CrNiMoA, and the threaded element is made of high-quality high-speed tool steel. The overall hardness is high and it is easy to disassemble and assemble.

- Barrel: The material is based on 45# steel, the inner hole uses high-quality double alloy bushings, and the barrels are connected with hexagonal high-strength bolts. There are barrel sections with different functions, such as feeding barrels, exhaust barrels, etc.

- Soft water cooling system: The soft water pipe is separated from the machine body for easy cleaning and maintenance. It is controlled by automatic water control solenoid valves and needle valves, and is equipped with a cooler of a certain capacity.

- Vacuum system: The vacuum pump is matched with a stainless steel vacuum water tank, which adopts an independent external design for easy cleaning and maintenance.

- Screen changing system: hydraulic blocking automatic screen changing is mostly adopted, which is a double-station, equipped with two perforated plates, including screen changer, hydraulic station, hydraulic cylinder, etc.

- Water pulling auxiliary machine: It is composed of a water tank, a suction dryer, a cantilever pelletizer, an extended vibrating screen, a wind-blown silo, etc., which is used for subsequent processing of the extrudate to obtain finished pellets.

Application fields

- Plastic industry: used for the modification and processing of various plastics, and the production of special plastic particles such as cable materials and PPR pipe materials.

- Rubber industry: natural rubber and synthetic rubber can be mixed, vulcanized, etc. to produce rubber particles with different properties for the manufacture of tires, rubber products, etc.

- Chemical industry: suitable for the processing of some special polymer materials such as polyurethane and polyether, and can also be used for the granulation of carbon powder and magnetic powder and the production of various silane cross-linking materials.

Lab Sheet Production Line Extruder Plastic Casting Machine >>

Small Plastic Rubber Extruder Granulator Machine for Laboratory >>

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529