High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

1-3 daysModel Number:

OLT-432Minimum Order Quantity:

1Mixing method:

Touch ScreenPower:

3∮, AC380VWarranty:

1 yearParameter

| Model | OLT-432(Single layer) |

OLT-432-2(Double layers) |

OLT-432-3(Three layers) |

| Screw diameter (mm) | 25 | 25 | 25 |

| L/D | 1:33 |

1:33 |

1:33 |

| Screw speed (Speed Adjustable) | 0~95rpm |

0~95rpm |

0~95rpm |

| Main Motor power (KW) | 2.2 | 2.2*2 | 2.2*3 |

| Die | Hanger Type |

Hanger Type |

Hanger Type |

| Die lip width | 300 or cunstomzied |

300 or cunstomzied |

300 or cunstomzied |

| Volume(H*W*D)mm | 2500*800*1700 | 2600*960*2100 | 3200*1200*2100 |

| Power Supply |

3∮, AC380V |

||

|

Special models can be desighed according to cunstomers' requirements |

|||

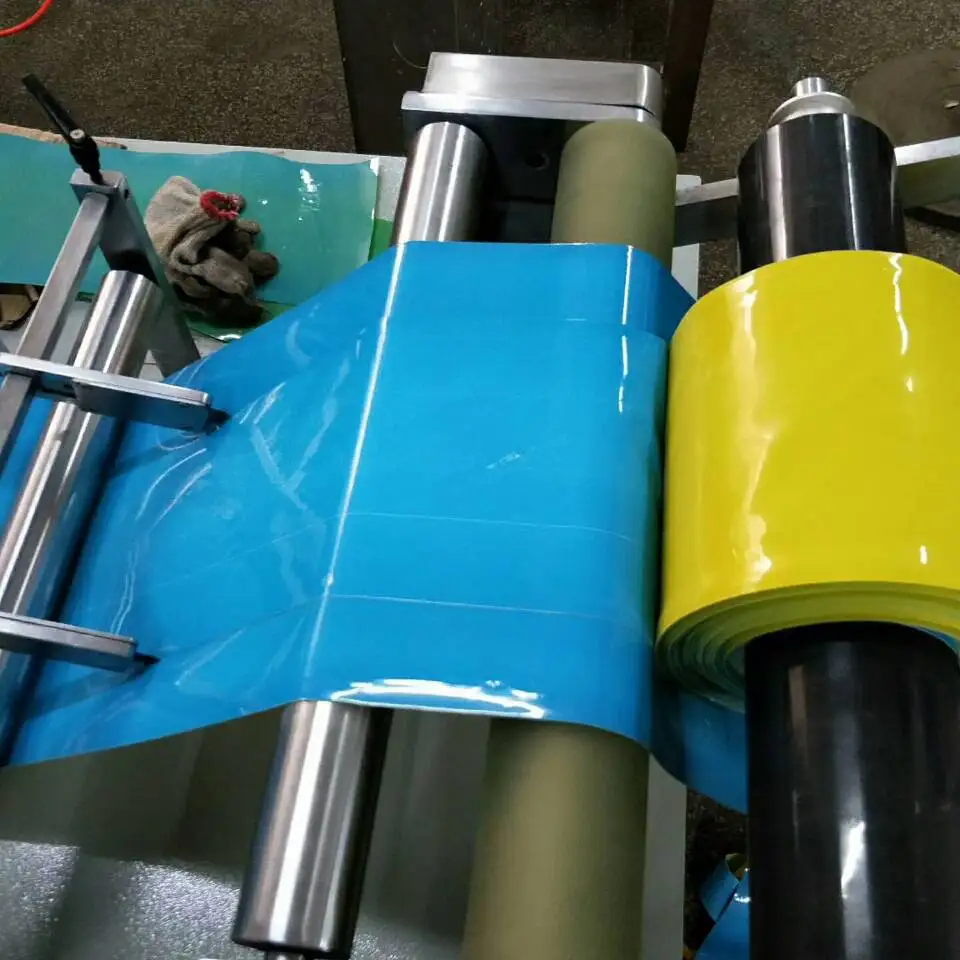

Detailed Images

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529