High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Item NO.:

XD-J6Lead Time:

7daysShipping Port:

XiaMen

Product Description

|

Model |

XD-J6 |

|

Power supply |

Single phase 110V / 220V±20% -50HZ |

|

Rate of work |

10-3500W |

|

Instantaneous maximum output power |

≥ 70KW |

|

Arc welding output |

Single point, automatic, intelligent operation, continuous arc welding, welding resistance output |

|

Continuous arc welding |

Welding wire0.2-3.0mm |

|

Automatic output current |

Output pulse current 5-200 (adjustable) |

|

Automatic welding time |

Output welding time 5-999 (adjustable) |

|

Automatic interval |

10-999 (adjustable) |

|

Continuous arc welding output current |

5-200 (adjustable) |

|

Resistance welding output |

high frequency1-10 (adjustable) low frequency1-10 (adjustable) |

|

Argon delay time |

0.9S |

|

Welding wire size range |

0.2mm-3.2mm |

|

Welding sheet thickness |

0.2mm-6.0mm |

|

Overlay welding thickness |

Arbitrary |

|

Cooling method |

Forced air cooling by fan |

|

Machine Size |

L 500mm*W 270mm *H 420mm |

|

Weight |

38KG |

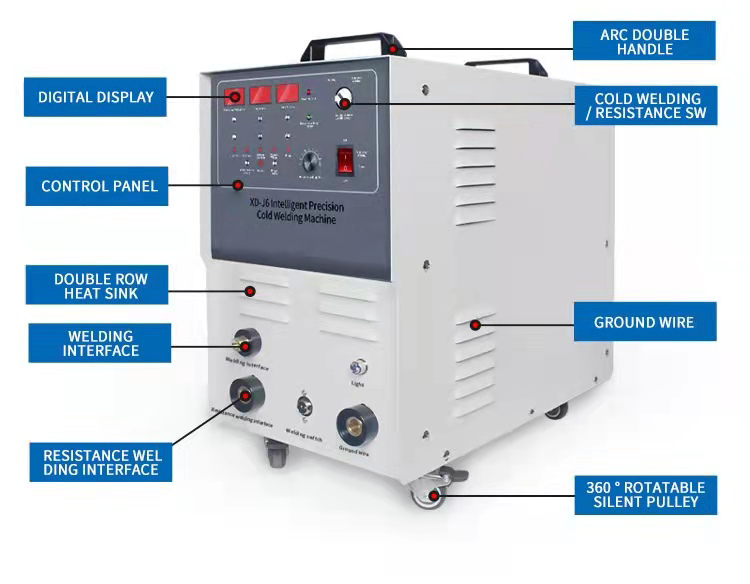

Eight advantages of XD-J6 intelligent precision cold welding machine

1.Fully intelligent digital control:Intelligent digital control;

2.Matching robotic arm:It can be matched with tooling, the only type can match with tooling in domestic;

3.Strong bonding strength:Complete metallurgical combination, can be processed by turning, milling, planing and grinding after welding;

4.Memory function:it can remember and store parameters,no need to worry about reset parameters when power is off;

5.High welding precision:It can be adjusted to the best power according to the characteristics of welding and welding repair;

6.Large & stable power:This machine is the most powerful machine in the market, and the repair quality will not decrease when the voltage fluctuates within the range of ±20%;

7.Humanized operation:The digital display is more visualized to observe the effect of different parameters after welding, and the operation is simple and easy to use;

8.Reliable quality:adopt to Germany imported technology microcomputer chip control.

Compare XD-J6 intelligent precision cold welding machine with traditional argon arc welding machine

1.Using the patented technology can not make the workpiece deform and edge-biting after welding;

2.Easy to use,no need professional welder;

3. Fish scale welding spot, almost no processing, zero cost after welding ;

4.Minor damage,low temperature after welding;

5.High repair precision, exquisite weld bead;

6.The fastest welding speed of non-tooling can reach 1000mm/min;

7.Stable welding power,and the repair quality is not reduced when the voltage fluctuates within ±20%;

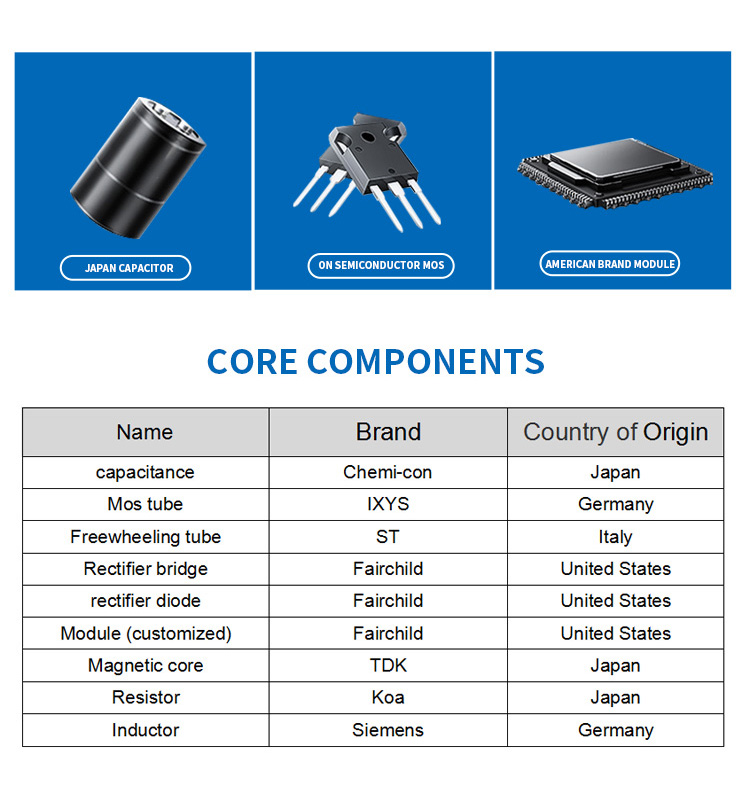

8.High quality components is more guaranteed.

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529