High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

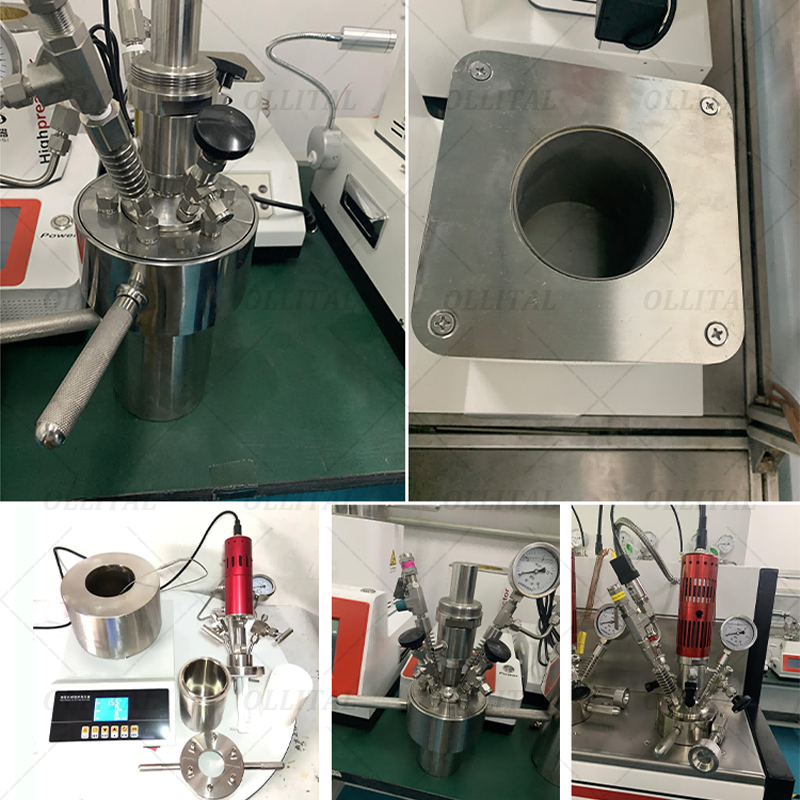

A microreactor is a small device used for chemical experiments and industrial production. Its main function is to simulate and reproduce the conditions of large-scale industrial reactions. Although it is smaller than many other reaction equipment, its design and structure still retain the main advantages of large-scale equipment.

Microreactors are usually made of corrosion-resistant hard materials, such as polytetrafluoroethylene or stainless steel. This material can withstand various corrosive substances that may be produced during chemical reactions. There are usually one or more containers inside the reactor to hold chemical reagents and reaction mixtures. These containers are usually sealed to prevent the escape of reaction products or the entry of external substances.

The design of the microreactor should include appropriate stirring and mixing systems so that the reactants can fully contact and mix. This can promote the progress of chemical reactions and make the reaction results more uniform and consistent. Some advanced microreactors can even simulate complex industrial production processes, including staged reactions and multi-stage reactions.

The operation of a microreactor usually requires certain skills and knowledge. The operator needs to understand the principles of chemical reactions and how to control the reaction conditions to obtain the desired results. The operator also needs to be familiar with the operation and maintenance of the equipment to ensure the long-term use of the equipment and the accuracy of the experimental results.

The main advantages of a microreactor are its small size and portability. Due to its small size, it can be used anywhere in a laboratory or factory without the need for special space or facilities. In addition, due to its portability, it can be easily transported between different places, making research and production processes more flexible.

In addition to the above advantages, a microreactor is also energy-saving and environmentally friendly. Due to its small size, it requires less energy to operate, saving energy costs. In addition, since it usually uses small amounts of reagents, it also produces less waste, reducing environmental impact.

In general, a microreactor is a powerful tool with important application value for chemical experiments and industrial production. Despite its small size, it is able to simulate and reproduce the conditions of large-scale industrial reactions, making research and production processes more flexible and efficient.

Click the following links to learn more about the product details and purchase information:

Contact us for professional consultation and technical support:

Tel: +86 159 6082 1529

Email: Kevin@ollital.com

Official website: www.ollital.com

Choose hydrogenation autoclave, let us move towards a more efficient and accurate product testing future together!

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529