High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

1-3 daysProduct Orgin:

ChinaModel Number:

OLT-HP-500Compliance:

CE CertifiedMinimum Order Quantity:

1Capacity:

500mlVoltage:

220VWarranty:

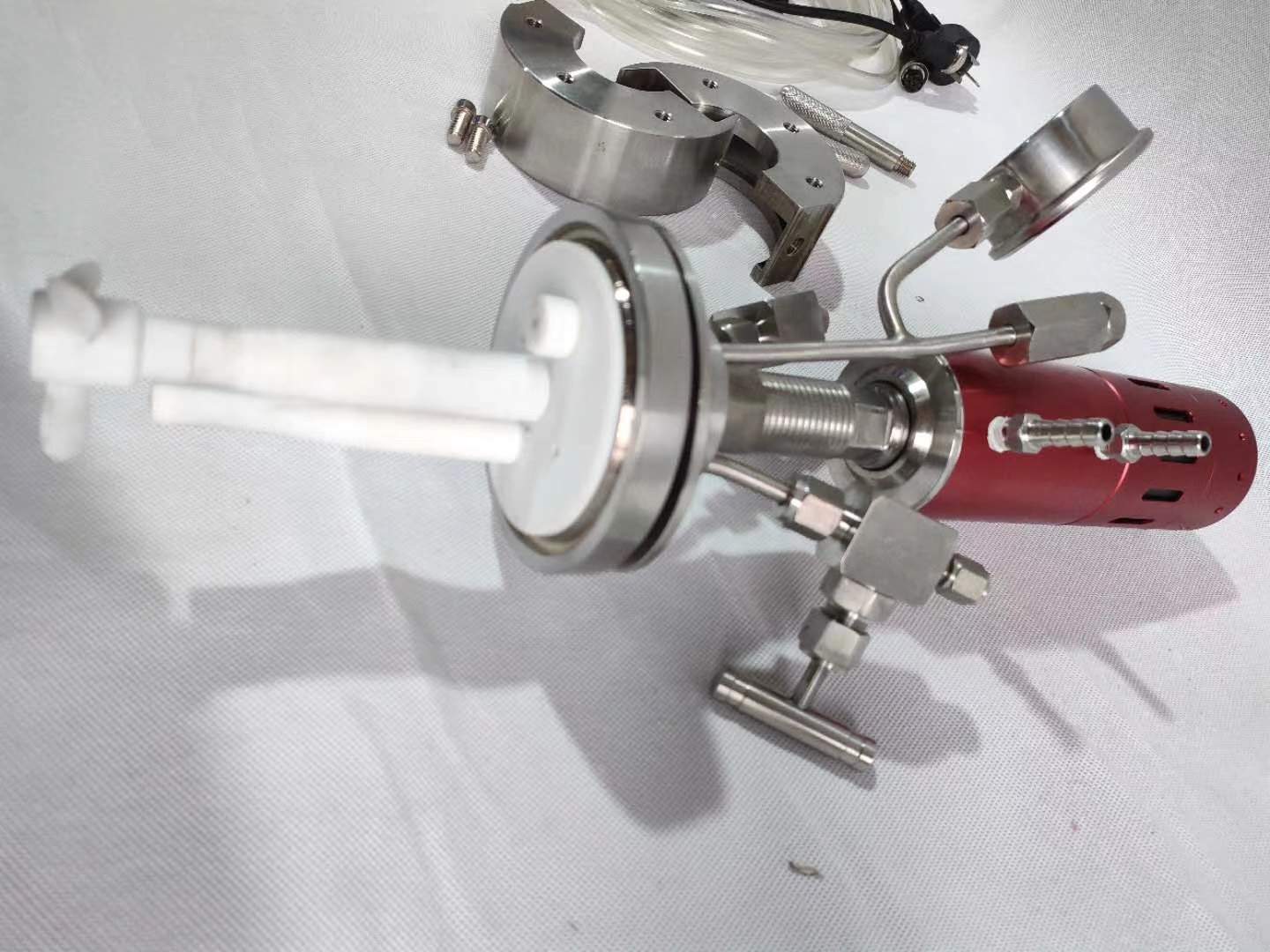

1 yearThis product suitable for all kinds of inflammable, explosive, precious liquids and other chemical medium mixing reaction, strong penetration is oil. Chemical. Organic synthesis, polymer polymerization. Food technology in vulcanization. Fluoride. Oxidation until the ideal reaction equipment without leakage.

Specification

|

Model

|

OLT-HP-10

|

OLT-HP-25

|

OLT-HP-50

|

OLT-HP-100

|

OLT-HP-250

|

OLT-HP-500

|

|

volume(ml)

|

10

|

25

|

50

|

100

|

250

|

500

|

|

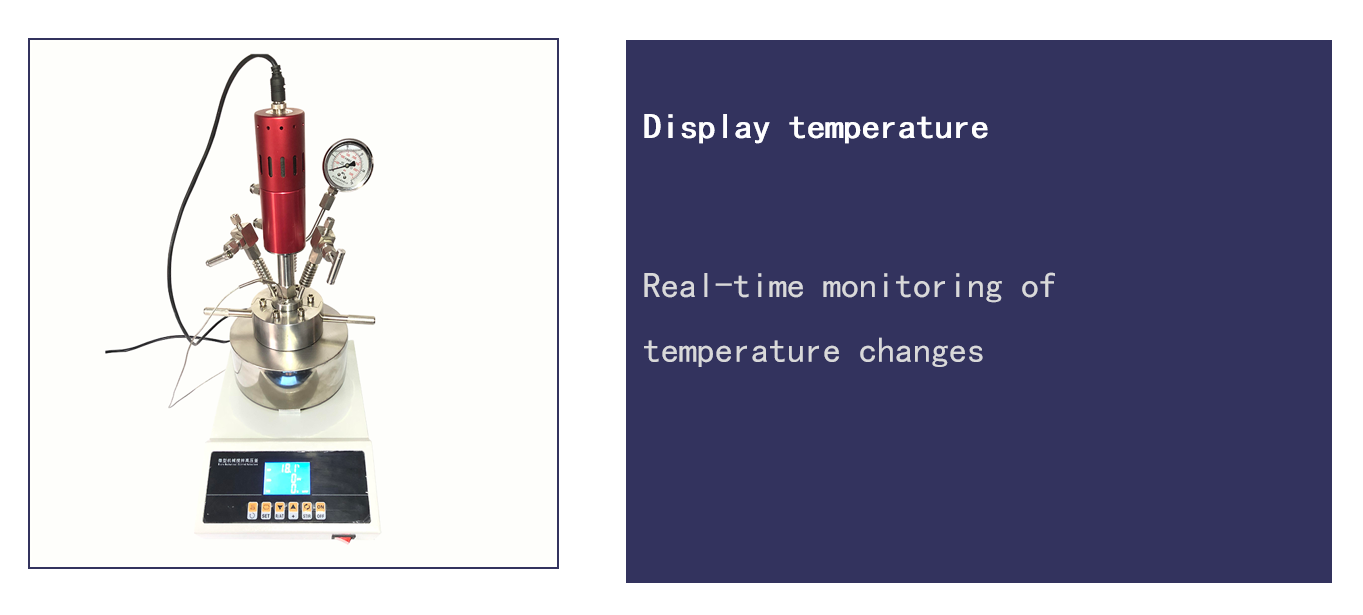

Service temperature(℃)

|

RT-350℃,Higher temperatures can be customized according to customer requirements

|

|||||

|

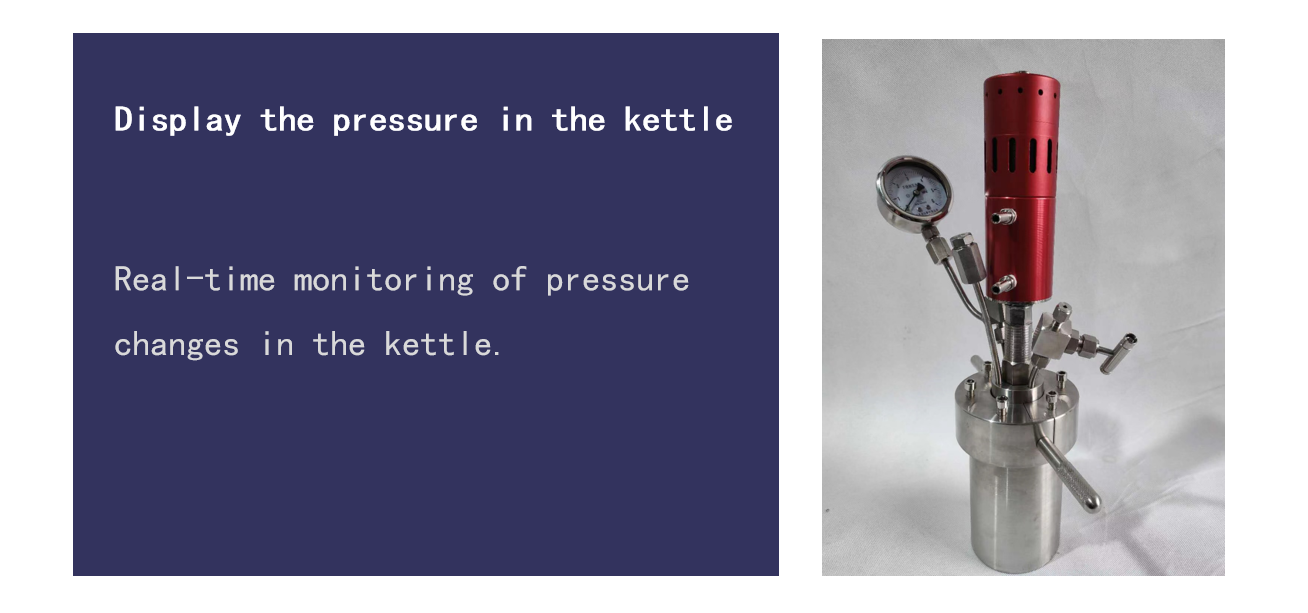

Use pressure(Mpa)

|

-0.1-10 Standard 10Mpa, customized according to customer requirements

|

|||||

|

heating power(w)

|

600

|

600

|

1000

|

1000

|

1500

|

1500

|

|

control mode

|

PID artificial intelligence adjustment, LCD digital display

|

|||||

|

Mixing form

|

Magnetic stirring

|

|||||

|

Mixing power(w)

|

80

|

|||||

|

Stirring speed(rpm)

|

0-1500

|

|||||

|

Positive and reverse regulation

|

Positive inversion

|

|||||

|

Temperature setting

|

Self setting function of temperature

|

|||||

|

safety protection

|

Set upper temperature limit, over temperature alarm, self power-off protection

|

|||||

|

Timing function

|

Working time and holding time can be set regularly

|

|||||

|

Timing function supply voltage

|

AC 108V-240V 50Hz

|

|||||

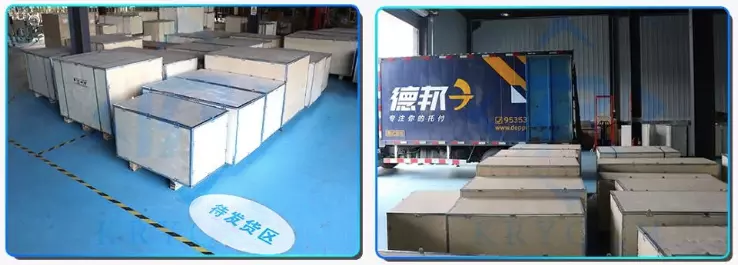

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529