High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Product Description

Technical Parameter

| DESCRIPTION | UNIT | DATA | |

| Injection unit | Shot volume | cm3 | 163.6 |

| Shot weight (PS) | g | 150.5 | |

| oz | 5.3 | ||

| Screw diameter | mm | 35 | |

| Injection pressure | Mpa | 256.9 | |

| Injection rate | g/s | 83.2 | |

| Screw L:D ratio | 24:01:00 | ||

| Max. injection speed | mm/s | 94 | |

| Screw stroke | mm | 170 | |

| Screw speed(stepless) | r/min | 0-208 | |

| Clamping unit | Clamping force | kN | 1200 |

| Opening stroke | mm | 360 | |

| Space between bars | mm*mm | 410*370 | |

| Max. Daylight | mm | 760 | |

| mold thickness(Min.Max) | mm | 145-400 | |

| Hydraulic ejection storke | mm | 120 | |

| Ejector number | 5 | ||

| Hydraulic ejection force | kN | 42 | |

| Power unit | Hydraulic system pressure | Mpa | 17.5 |

| Pump motor | kw | 16 | |

| Heating capacity | kw | 9 | |

| Number of temp control zones | 4 | ||

| General | Dry cycle time | s | 1.9 |

| Oil tank capacity | L | 165 | |

| Machine dimensions(LxWxH) | m*m*m | 4.59*1.23*1.62 | |

| Machine weight | kg | 3500 |

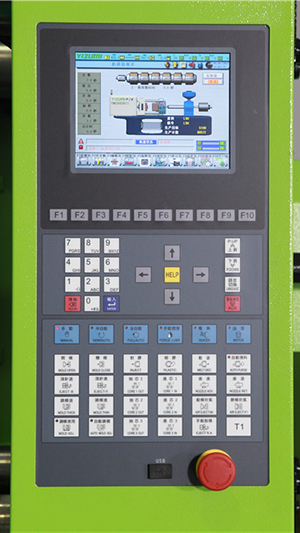

Control System

MH9118 controller: fast speed, accurate control, easy operation, program for multiple processes, powerful

1. MH9118 controller which runs fast and clock rate up to 140MHZ

2. 8"TFT 256-color LCD with independent CPU control

3. Machine control frequency of 140MHZ, scanning time of 1ms, fast response and accurate control

4. 100 sets of molding data storage with USB port

5. Production quality control with main process parameter statistics

Clamping Unit

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529