High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Product Orgin:

ChinaShipping Port:

XiamenPayment:

T/TModel Number:

OLT-100Compliance:

1~10LMinimum Order Quantity:

1Operation method:

Smart PID controlPower:

1.5kwWarranty:

1 YearWeight:

300

Lab Fermentation Bioreactor For Bacteria

Product Description

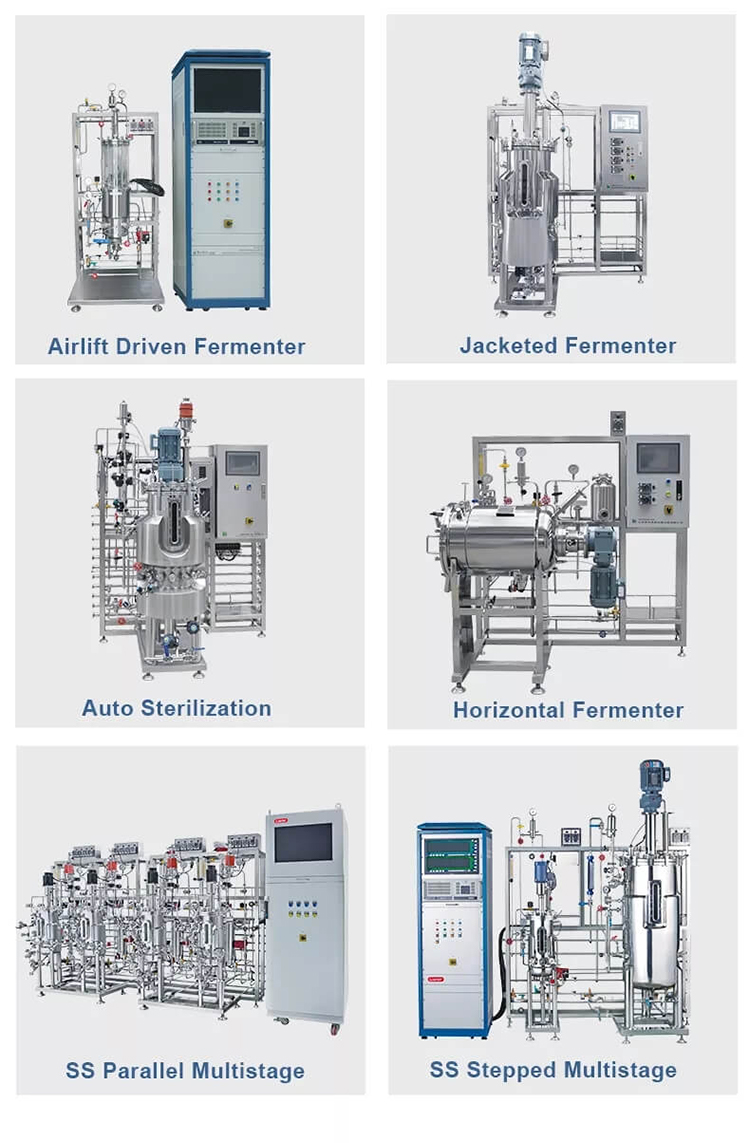

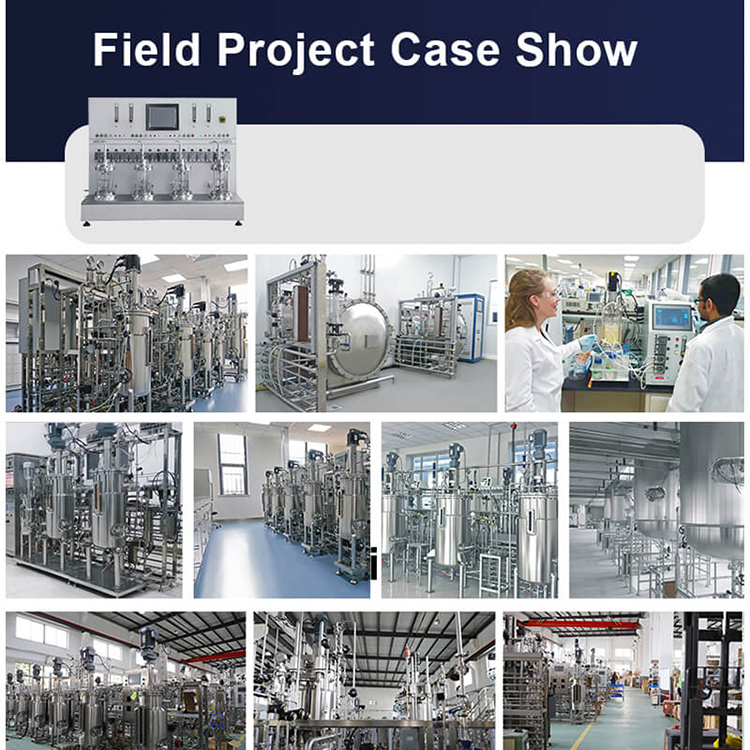

OLLITAL offers you not only with scalable range of glass and stainless steel bioreactors, but also with multi-parallel and multistep bioreactors. Based on our thorough understanding of bioreactors, rich experience for scaling up benchtop fermentors to processing system, and excellent control system for temperature, rpm, PH, DO, antifoam, feeding, aeration and pressure, you will benefit from our turnkey solution service.

Technical Data

Controller Technical Data

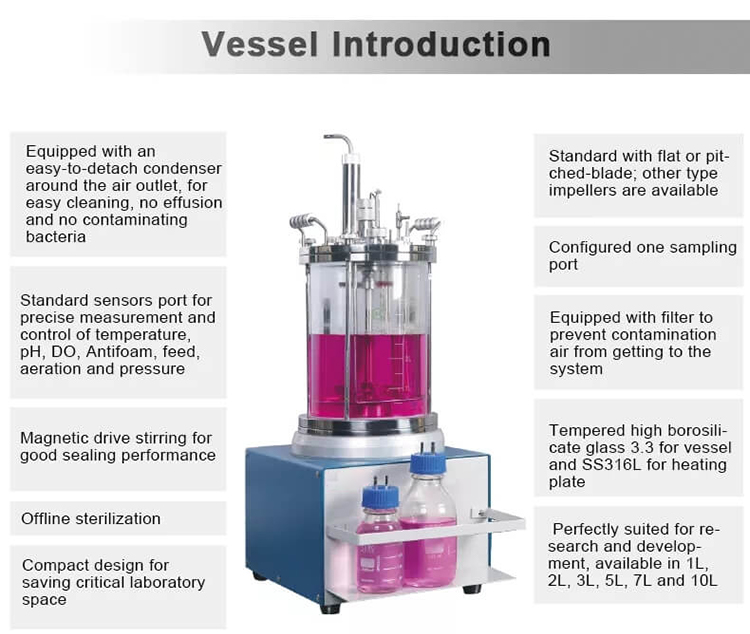

Glass Vessel Technical Data

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529