High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Parameter

| Model | OLT-250 | OLT-320 | OLT-350 |

| Film Width | Max.250mm | Max.320mm | Max.350mm |

| Bag Length | 65-280mm | 65-280mm | 65-330mm |

| Bag Width | 30-110mm | 30-150mm | 50-160mm |

| Product Height | Max.40mm | Max.40mm | Max.45mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm |

| Packing Speed | 40-230 bags/min | 40-230 bags/min | 40-230 bags/min |

| Power Specification | 220V,50/60Hz,2.4KW | 220V,50/60Hz,2.4KW | 220V,50/60Hz,2.4KW |

| Machine Size | 3770*670*1450mm | 3770*720*1450mm | 4020*770*1450mm |

| Machine Weight | 500KG | 500KG | 500KG |

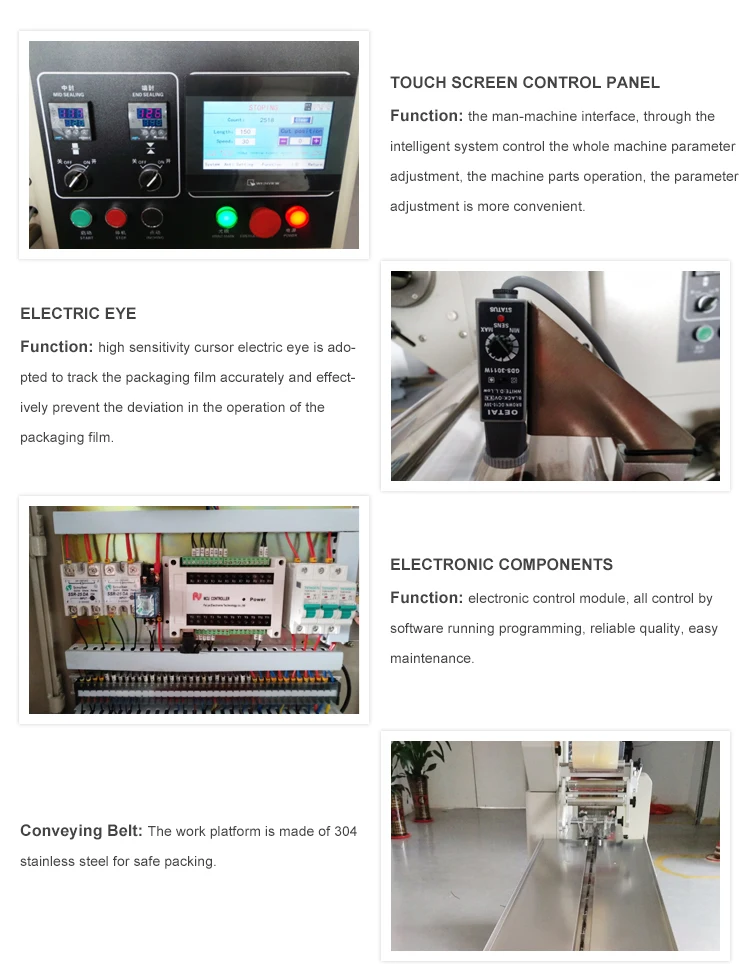

Detail Image

Features

1. Dual frequency conversion control, bag length can be set and cut in one step, saving time and film.

2. Interface features easy and quick setting and operation.

3. Self failure diagnosis, clear failure display.

4. High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

5. Temperature independent PID control, more suitable for packaging different materials.

6. Positioned stop function, without sticking knife or wasting film.

7. Simple driving system, reliable working, convenient maintenance.

8. All controls realized through software, easy for function adjusting and technical upgrade.

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529