High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Item NO.:

MH079Lead Time:

7daysShipping Port:

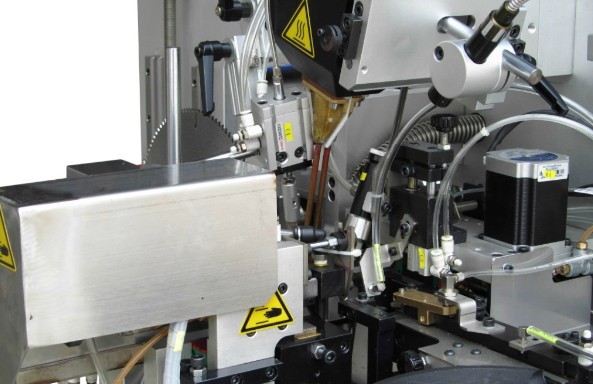

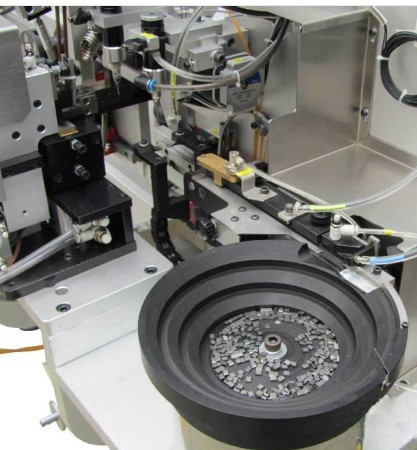

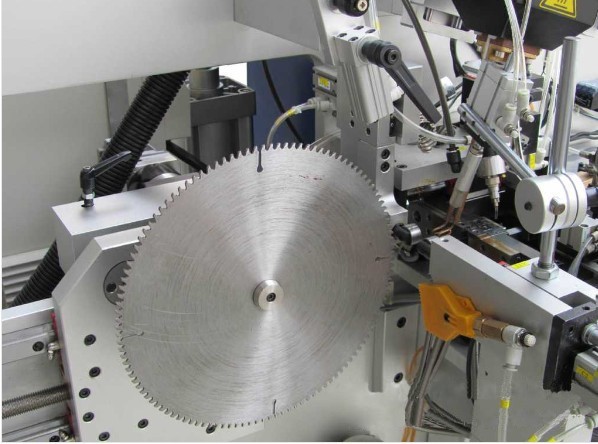

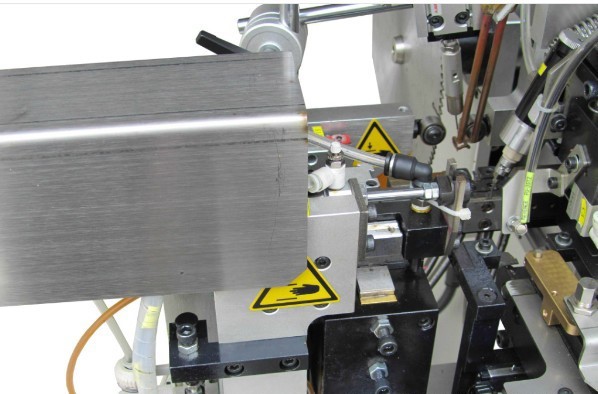

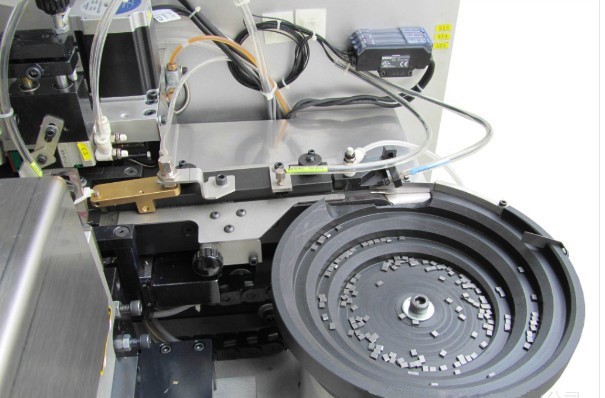

XiaMenCircular saw blade carbide tips automatic brazing machine

Automatic choose tooth, feeding, soldering lug fold to mould, centering and welding.

Accurate and durable welding quality.

Advanced heated controller, control temperature automatically in welding work, micro adjustment temperature of automatic tempering.

Centering precise, welding secure.

Latest system for teeth type choose.

CNC control, safety performance, has memory and search function.

Small size of whole machine, low power consumption, high working efficiency.

Easy to operation, clear graph indexing

|

Product: |

CNC Circular saw blade brazing machine |

|

Saw blade Dia |

120mm-790mm |

|

Hook angle |

-10 to +25 degree |

|

Saw tips length |

3.5-13mm |

|

Saw tips width |

1.5mm-6.5mm |

|

Saw tips thickness |

1.5mm-3mm |

|

High frequency power |

6kw |

|

Air pressure |

6KG/cm2 |

|

Total power |

6.5kw |

|

Ventilate capacity |

>5meter/min |

|

Cooling power |

1.5kw |

|

Cooling water flow |

22L/min |

|

Weight: |

430KG |

|

Overall size: |

1570*1100*1600mm |

|

Power |

220V,50hz |

Product Overview

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529