High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Item NO.:

CR2100-100B-14TWLead Time:

7daysShipping Port:

XiaMen

Adopt DSP full digital control system:

1. Accurate control in constant current mode,current fluctuation does not exceed 0.5 A, high repeat accuracy, basically no deviation.

2. It can realize continuous segmented heating and can be applied to various complex environments.

3. Color screen display, convenient and easy to operate, can be used after simple training.

4. Complete protection functions, under voltage, water shortage, over current, overheat protection of the core components of the equipment.

5. Rich interface forms to facilitate communication with PLC and computer.

6. Program control, easy to achieve system upgrade.

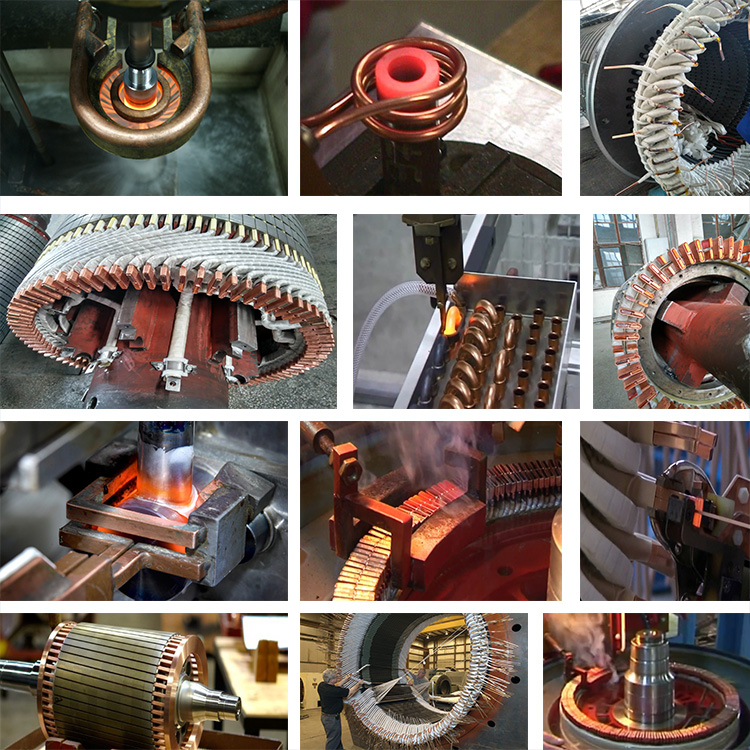

Application Ranges for induction welding machine:

1. metal tube welding:such as copper tube,steel tube, and aluminum tube’s butt welding, plug welding and welding sets.

2. alloy cutter welding:such as alloy turning tool, milling cutter, planer, saw blades, reamer, boring knife.

3. carbide saw blade welding:diamond saw blade welding, marble saw blade welding, woodworking saw blade welding,cut grass piece of welding, cut aluminum welding.

4. metal welding:such as: towel rack, soap nets, towel holder, auto-accessories, motor accessories, metal terminals, hardware pieces, electric heating tube parts and fasteners.

5. customized service:make machine according to customers' actual working situation.

CR2100 is our water cooling system with detachable induction coil.

With different coil, CR2100 can realize different applications like brazing, hardening, annealing, bolt untighten, paint removal, straightening, etc.

Characters:

Hand-held transformer are designed for your easy manual manipulation, and also can be integrated into robot arm for automatic production.

Induction coils are easy for assemble and dismantle from hand-hold transformer, so you can connect with different coil for different application.

>1000℃

with enough power, targed temperature can be reached within seconds.

Steel, stainless steel, copper, aluminum, titanium, etc

Model NO.

Input

Output

Cooling water pressure/ flow rate

appearance

IP

degree

CR2100-010B-14TW1

power:10KVA

voltage:3-phase/400V

freq.:50-60Hz

current:15A

power:8kW

(duty cycle100%) freq.:10-40KHz

4~6 bar,

≥12L/min

IP23

CR2100-015B-14TW1

power:15KVA

voltage:3-phase/400V

freq.:50-60Hz

current:22A

power:12kW

(duty cycle100%) freq.:10-40KHz

IP23

CR2100-020B-14TW1

power:20KVA

voltage:3-phase/400V

freq.:50-60Hz

current:30A

power:16kW

(duty cycle100%) freq.:10-40KHz

IP23

CR2100-025B-14TW1

power:25KVA

voltage:3-phase/400V

freq.:50-60Hz

current:37A

power:20kW

(duty cycle100%) freq.:10-40KHz

IP23

CR2100-030B-14TW1

power:30KVA

voltage:3-phase/400V

freq.:50-60Hz

current:45A

power:24kW

(duty cycle100%) freq.:10-40KHz

4~6 bar,

≥19L/min

IP23

CR2100-035B-14TW1

power:35KVA

voltage:3-phase/400V

freq.:50-60Hz

current:53A

power:28kW

(duty cycle100%) freq.:10-40KHz

IP23

CR2100-040B-14TW1

power:40KVA

voltage:3-phase/400V

freq.:50-60Hz

current:60A

power:32kW

(duty cycle100%) freq.:10-40KHz

IP23

CR2100-050B-14TW1

power:50KVA

voltage:3-phase/400V

freq.:50-60Hz

current:75A

power:40kW

(duty cycle100%) freq.:10-40KHz

IP23

CR2100-060B-14TW1

power:60KVA

voltage:3-phase/400V

freq.:50-60Hz

current:91A

power:48kW

(duty cycle100%) freq.:10-40KHz

4~6 bar,

≥25L/min

IP23

CR2100-080B-14TW1

power:80KVA

voltage:3-phase/400V

freq.:50-60Hz

current:121A

power:64kW

(duty cycle100%) freq.:10-40KHz

IP23

CR2100-100B-14TW1

power:100KVA

voltage:3-phase/400V

freq.:50-60Hz

current:152A

power:80kW

(duty cycle100%) freq.:5-25KHz

4~6 bar,

≥35L/min

IP23

CR2100-120B-14TW1

power:120KVA

voltage:3-phase/400V

freq.:50-60Hz

current:182A

power:96kW

(duty cycle100%) freq.:5-25KHz

IP23

CR2100-160B-14TW1

power:160KVA

voltage:3-phase/400V

freq.:50-60Hz

current:243A

power:128kW

(duty cycle100%) freq.:5-25KHz

4~6 bar,

≥50L/min

IP23

CR2100-200B-14TW1

power:200KVA

voltage:3-phase/400V

freq.:50-60Hz

current:303A

power:160kW

(duty cycle100%) freq.:5-25KHz

IP23

CR2100-250B-14TW1

power:250KVA

voltage:3-phase/400V

freq.:50-60Hz

current:380A

power:200kW

(duty cycle100%) freq.:5-25KHz

4~6 bar,

≥60L/min

IP23

CR2100-300B-14TW1

power:300KVA

voltage:3-phase/400V

freq.:50-60Hz

current:456A

power:240kW

(duty cycle100%) freq.:5-25KHz

IP23

Some of applications of 10kw portable handheld induction heater/induction heating machine for metal heat treatment:

HHT(hand held transformer) is easy to operate, and can be integrated with Robot Arm for automotion production, two buttons to control the machine working:

Inductors are important part of induction heater, so it is precisely designed, manufactured by good quality material, and tested many times before outgoing, it is detachable, and can be customized accoridng to your needs:

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529