High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Product Orgin:

ChinaShipping Port:

XiamenPayment:

T/TModel Number:

OLT-5/7/10L OLT--10L-2KLMinimum Order Quantity:

1Operation method:

Voltage:

220/240/380 Volt 50/60 HzPower:

0.75KW-75KWWarranty:

1 YearWeight:

50- 15000 Kgs

Lab Fermentation Bioreactor For Bacteria

Product Description

Technical Data

|

Total Volume

|

5/7/10L

|

10L-2KL

|

|

Vessel

|

316L Stainless Steel +Borosilicate Glass

|

316L stainless steel

|

|

Stirrer

|

Top driven or bottom Driven by magnetic Coupling

|

|

|

Sterilization

|

In suit Sterilization(steam source external)or In autoclave

|

|

|

Basic Features

|

Temperature,RPM,PH,DO,Antifoam,Feed,Aeration,Pressure,weight culture medium,weigh feed,Exhaust O2&CO2,Offline Operation:CER,OUR,RO,KLa

|

|

|

Advanced Features

|

Level,Weight Feed,Multi-Feeds, Mehanol&Ethanol,Exhaust O2&CO2

|

|

|

Features

|

Automatic control and monitor rmp ,temperature,PH,DO,foam,air flow rate,weight exhaust O2&CO2,offline parameter(bacteria number,base,nitrogen,valence)could be input manually

|

|

|

with Tail Gas Analysis system (Multichannel)

|

Measuring;CO2 online (auto) range :0-5%±0.5%

O2 online(auto) range:11-21%±0.5% |

|

|

Controller

|

OLT-7000 Technical parameter

|

|

|

|

Parameter

|

Guideline

|

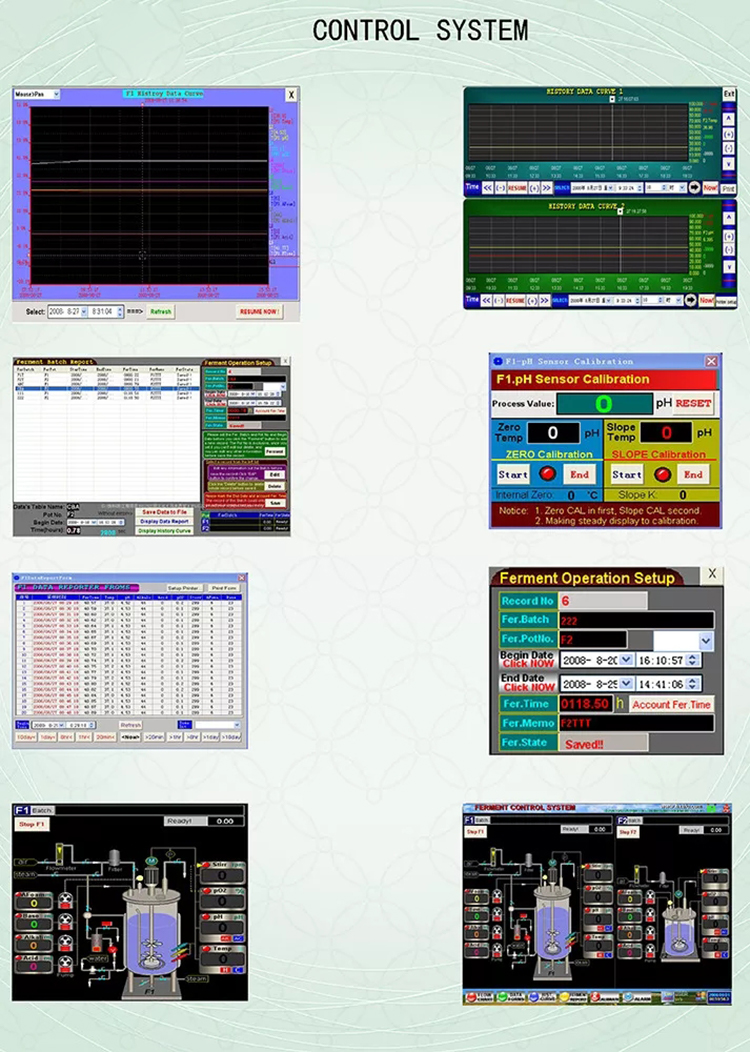

Controller data processing function

|

|

|

pH

|

Displaying range: 0.00~14.00±0.01

Auto-control range:2.00~12.00±0.05 Fermentation process control (According to the fermentation time, auto- control pH fluent, at least10 parts) |

pH value historical and trend curve analysis Acid, alkali dosage curve analysis

Batch report form analysis Acid, alkali total dosage record Keep |

|

|

Antifoam

|

Automatic PID control and alarm

Fermentation process control (According to the fermentation time, auto- control antifoam fluent, at least10 parts) |

Antifoam value historical and trend curve analysis Foam error state record

antifoam total dosage record Batch report form analysis Keep |

|

|

Rpm

|

Automatic enactment and control(50~1000rpm±5‰)

Fermentation process control (According to the fermentation time, auto-control rev fluent, at least10 parts) |

Rpm value historical and trend curve analysis Batch report form analysis Keep and deliver data

|

|

|

Temperature

|

Temperature of cooling water: +5℃-65℃±0.2℃

Fermentation process control (According to the fermentation time, auto- control temperature fluent, at least10 parts) |

Temperature value historical and trend curve analysis Batch report form analysis Keep

|

|

|

Feeding

|

PID automatic enactment and control

Fermentation process control (According to the fermentation time, auto- control feeding fluent, at least10 parts) |

Feeding value historical and trend curve analysis

Feeding total dosage record Batch report form analysis keep |

|

|

Pressure

|

Manual control, instrument display

|

|

|

|

Air flux

|

Manual control, instrument display

|

||

Our Advantages

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529