High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

7-15 daysProduct Orgin:

ChinaShipping Port:

XiamenModel Number:

Y300-PROMinimum Order Quantity:

1Voltage:

220/240/380 Volt 50/60 HzWarranty:

1 Year

The High Shear Dispersing & Emulsifying Homogenizer is an advanced processing solution engineered for applications requiring rapid particle size reduction, efficient dispersion, and stable emulsion creation. Using a precision-engineered rotor–stator system, the equipment generates intense hydraulic shear to refine droplets and particles to micron or even sub-micron levels.

This system is widely used in laboratories, pilot plants, and industrial production environments where accuracy, repeatability, and high processing efficiency are critical.

Inside the mixing head, the high-speed rotor pulls materials into the stator chamber, where they undergo:

Intense shear impact

High-frequency cutting

Centrifugal dispersion

Rapid circulation back into the tank

Each cycle repeats thousands of times per minute, producing exceptionally uniform, stable, and finely dispersed emulsions—even with high-viscosity formulations or challenging powders.

|

Equipment parameters model |

Y300-PRO |

|

power |

850W |

|

power supply |

220V,50Hz |

|

power supply (H₂O) |

150-40000mL |

|

Maximum processing viscosity |

30000cP |

|

speed range |

0-15000rpm |

|

RPM display |

Digital display |

|

Speed control |

Stepless Speed Regulation |

|

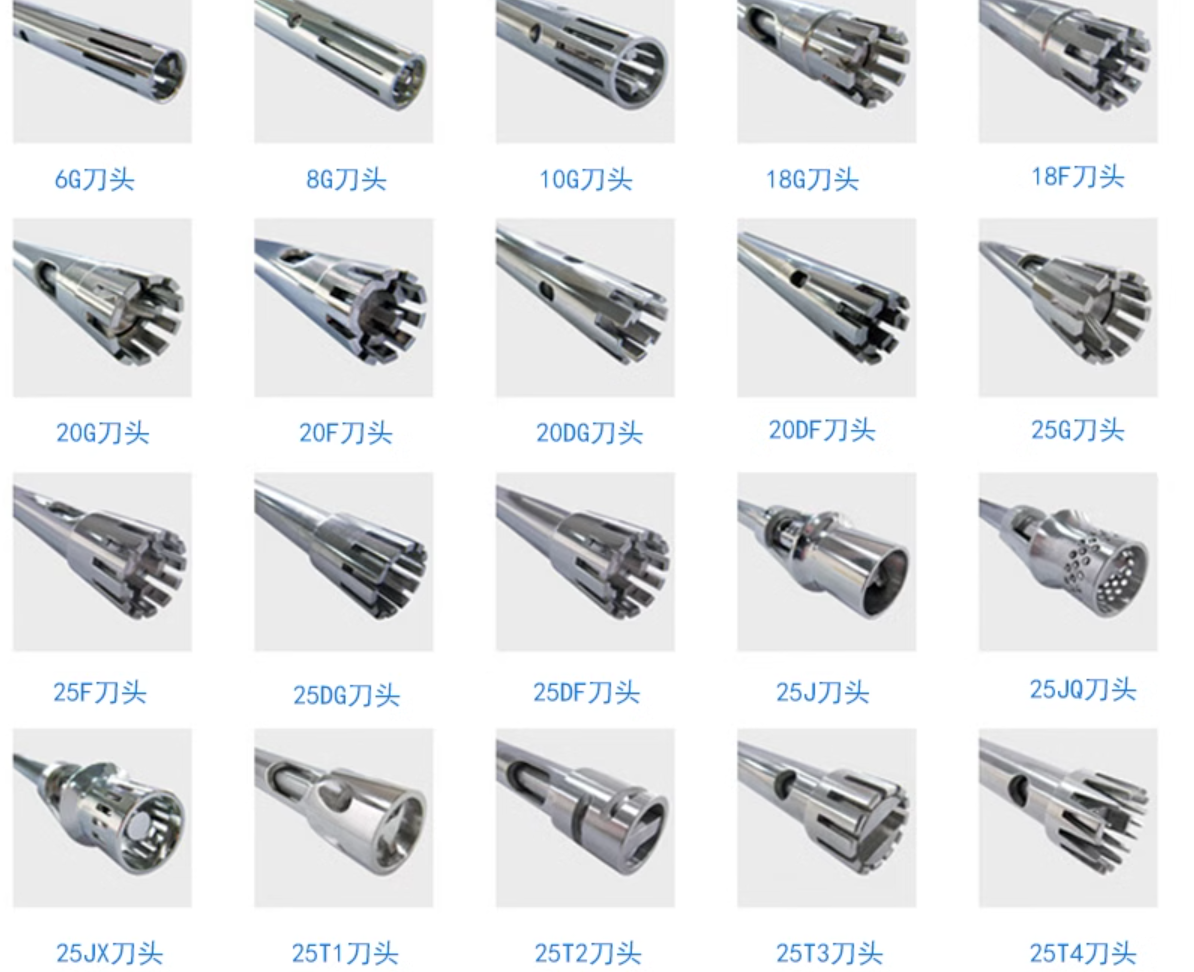

Standard stator configuration |

inclined chute |

|

Material contact materials |

SS316L |

|

Bushing material |

copper alloy |

|

Permit ambient temperature |

5-40℃ |

|

Allow relative humidity |

≤80% |

|

Process type |

batch processing |

|

Work stand, base |

Standard configuration |

|

outline dimension |

215×310×730 |

|

weight |

~10kg |

|

Packaging |

carton |

|

Diameter of blade tip |

70mm |

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529