High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

7-15 daysProduct Orgin:

ChinaShipping Port:

XiamenModel Number:

FJ200-300Minimum Order Quantity:

1Voltage:

220/240/380 Volt 50/60 HzWarranty:

1 Year

Homogenizer is a device used to evenly mix liquid, liquid and solid, or liquid and gas to form a stable emulsified system. Its main function is to disperse large particles or droplets into fine particles or droplets through high shear force, thereby achieving the purpose of homogenization and emulsification. Homogenizer is widely used in food, cosmetics, health care products, chemical industry and other industries, and is used to produce milk, juice, cream, emulsion, cosmetic emulsion and other products.

- High shear force: Strong shear force is generated through the narrow gap between the high-speed rotating rotor and the stator, which disperses large particles or droplets into fine particles or droplets.

- Collision and cavitation: When the liquid passes through a narrow gap at high pressure, it produces violent collisions and cavitation, which further break up the particles or droplets to form a uniform dispersion system.

- Eddy currents and micro-mixing: The eddy currents and turbulences generated by high-speed rotation help to mix evenly, so that the molecules between different components can fully contact and mix.

|

Product model

|

FJ200

|

FJ200(LED)

|

FJ300(LED)

|

|

Speed range

|

300-23000r/min

|

300-23000r/min

|

300-18000r/min

|

|

Processing capacity

|

30-1500ml

|

30-1500ml

|

100-13000ml

|

|

Input power

|

280W

|

280W

|

510W

|

|

Output power

|

200W

|

200W

|

300W

|

|

Dimensions

|

250x350x600mm

|

250x350x600mm

|

250x350x600mm

|

|

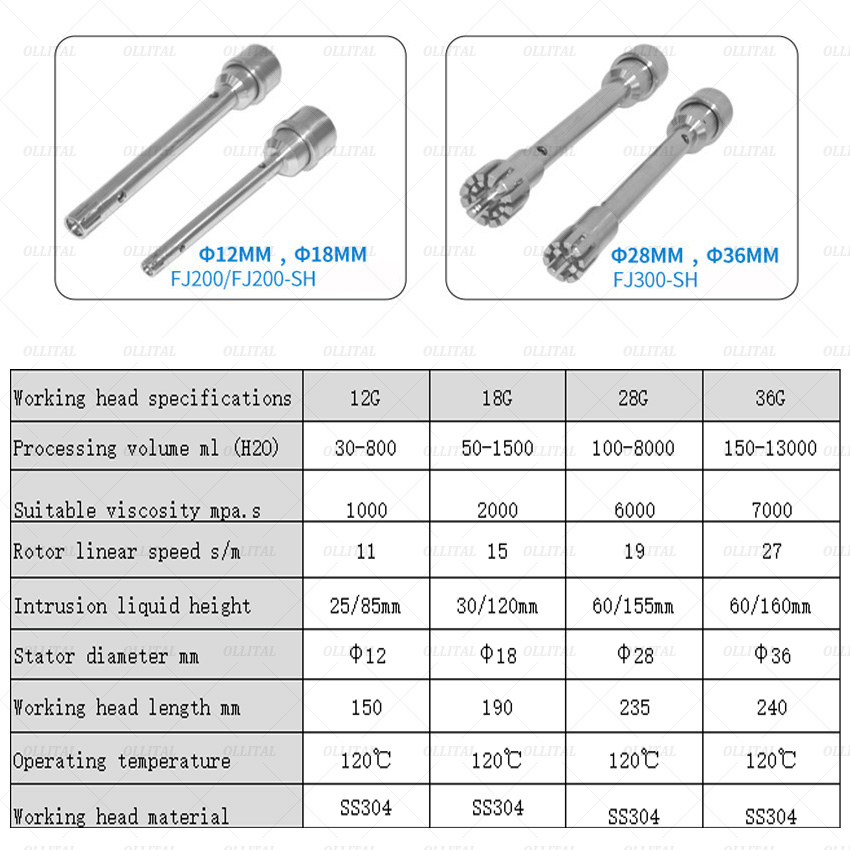

Working head configuration mm

|

φ12mm,φ18mm

|

φ12mm,φ18mm

|

φ28mm,φ36mm

|

|

Working method

|

Intermittent

|

Intermittent

|

Intermittent

|

|

Power supply

|

AC220 V50HZ

|

AC220 V50HZ

|

AC220 V50HZ

|

|

Rated torque

|

83N.cm

|

68N.cm

|

68N.cm

|

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529