High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

7-15 daysProduct Orgin:

ChinaShipping Port:

XiamenModel Number:

DT25-easy clean digitalVoltage:

220/240/380 Volt 50/60 HzPower:

customizeWarranty:

1 Year

Our High Shear Emulsifying Mixer & Homogenizer is designed for rapid dispersion, emulsification, and homogenization of liquid–liquid and liquid–solid materials. Equipped with a precision rotor–stator system, the unit delivers intense shear force to break particles down to micron or sub-micron levels, ensuring exceptional uniformity and stability of the final product.

This equipment is widely used in cosmetics, pharmaceuticals, food processing, fine chemicals, adhesives, and laboratory R&D environments where consistent emulsification and high-efficiency mixing are essential.

Modern formulations demand:

Traditional mixers cannot meet these needs. Our high shear system solves the industry's most common pain points with professional-grade engineering.

| Common pain points | Our Solution |

| Unsmooth emulsification, prone to stratification | High shear force & micron-level homogenization |

| Powder clumping | High-speed dispersion structure for efficient agglomeration |

| High viscosity makes mixing difficult | Strong circulating flow field + high-torque motor |

| Mixing dead zones | 3D circulating design with no dead angles |

| Equipment overheating, unable to operate continuously | Optimized heat dissipation + industrial-grade durable system |

| Time-consuming cleaning | Removable structure for quick CIP/hand washing |

| Batch inconsistency | Precise speed control for high repeatability |

| High noise and vibration | Dynamic balancing for smooth operation |

Key Features:

- 1300W silent brushless motor: Eliminates carbon powder contamination risks, extends motor lifespan, and ensures quiet operation.

- Broad speed range: 4,000–26,000 rpm.

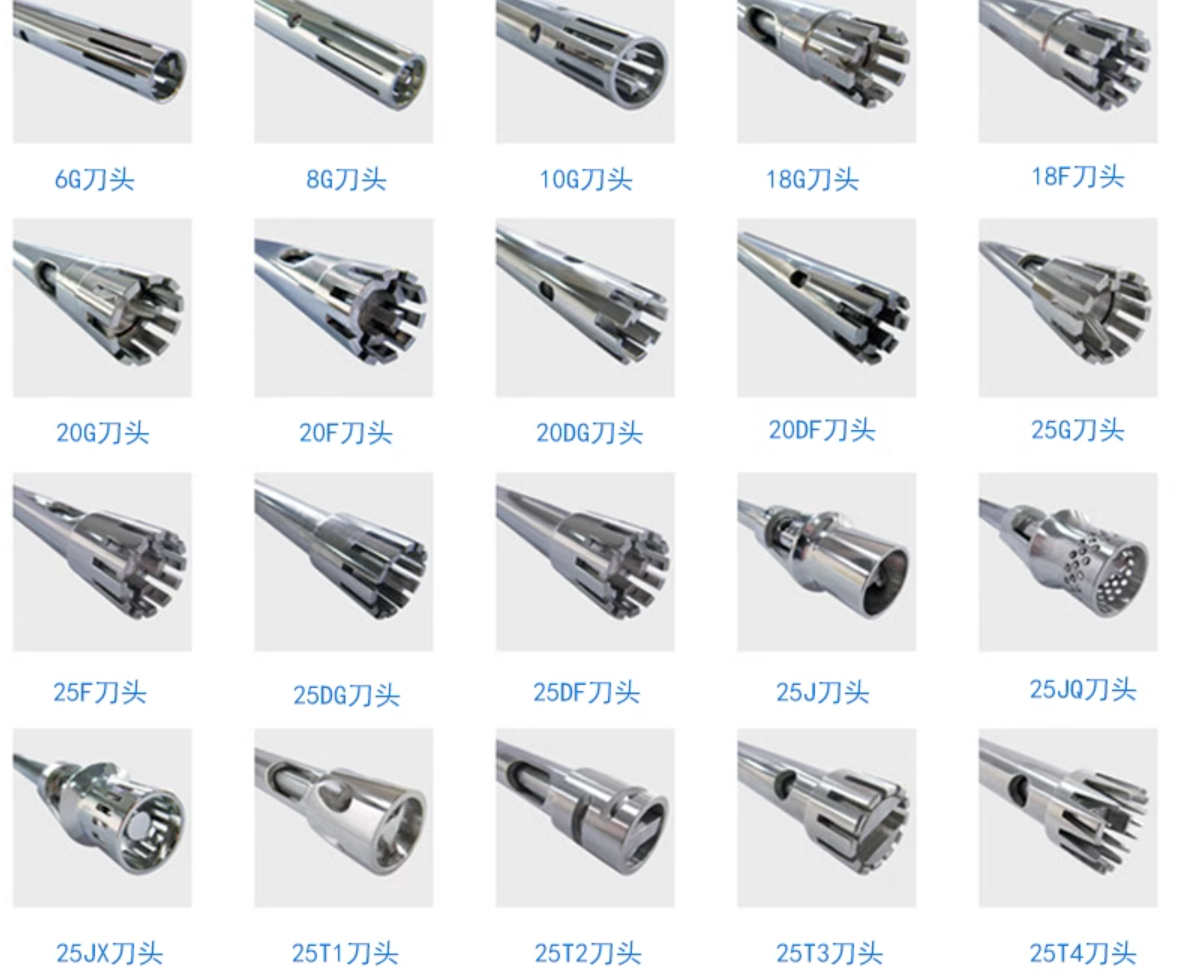

- High-power motor with specialized blades: Processes materials up to 100,000 cP viscosity. Multiple working heads adapt to varying batch sizes and applications.

- Timer/countdown function: Enhanced safety protocols.

- LCD display with rotary speed control: Intuitive interface for precise and effortless operation.

|

Technical Specifications model |

DT25-easy clean digital |

|

Voltage v |

200~240 |

|

Hz |

50~60 |

|

input power w |

1350 |

|

input power w |

1050 |

|

Principles of Electric Motors |

Brushless DC motor |

|

RPM range |

4000-26000 |

|

Maximum processing viscosity for standard cutting head |

15000CP |

|

rotational speed accuracy |

±100 |

|

RPM display |

Liquid crystal display |

|

Speed regulation method |

knob adjustment |

|

knob adjustment ml |

0.2~20000 |

|

knob adjustment min |

0~999 |

|

Time display |

Liquid crystal display |

|

Temperature measurement range℃ |

-10~199 |

|

Set instrument dimensions mm |

200*315*780 |

|

Weight kg |

10 |

Our high shear emulsifying mixer and homogenizer is engineered for laboratories, pilot plants, and industrial production lines that need stable emulsions, efficient dispersion, and consistent fine-particle performance. Reliable, durable, and easy to operate, this equipment provides outstanding results for cosmetic, food, pharmaceutical, and chemical applications.

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529