High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Model Number:

XB-OTS-800C-BCompliance:

CE CertifiedMinimum Order Quantity:

1Capacity:

800LVoltage:

108V-380V 50/60HZWarranty:

3 yearPackaging Details:

Standard export wooden boxDelivery Time:

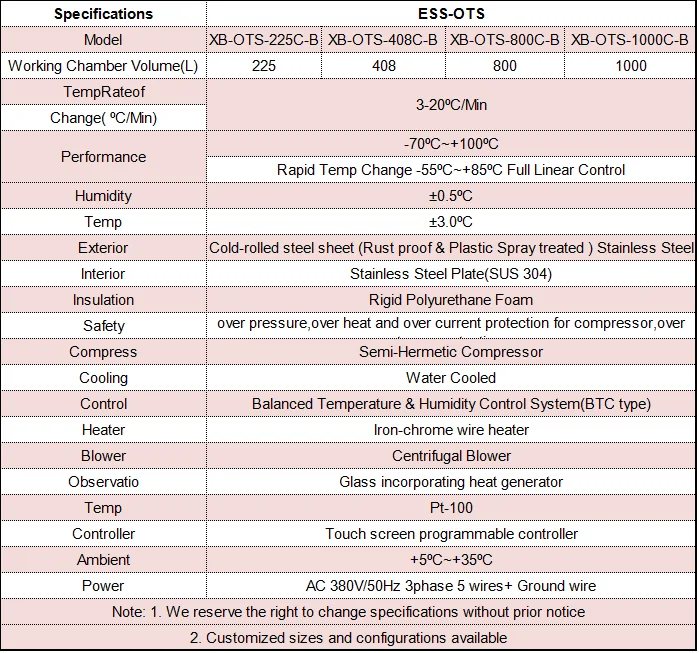

8-10 DaysFast Temperature Change Cycle test Chamber

Rapid Rate Change Temperature Test Chamber is widely applied for quality inspection for all types of electric products, electric appliance, and products from communication, instrument, automobile, plastic, metal, food, chemical, building materials, medical and aerospace industries by constant high low temperature change, damp heat etc environment simulation reliability test.

1.Reasonable structural design, rapid cooling rate.

1.Reasonable structural design, rapid cooling rate.

2. Imported refrigeration system, internal with SUS#304 high temperature resistant stainless steel.

3. More than 30% energy saving is achieved.

4. The test specimen can be easily observed via observation window,

5. Easy to Operate, install and maintain.

6.ational Construction and fast cooling rate

7.Frequency conversion control of wind speed.

8.Adopts international brand of imported parts for cooling system to improve operation reliability

9.Touch screen controller, friendly Man-Machine interface and safety device to ensure simple operation and easy maintenance.

10.Standards Implemented and met

11.GB10592-89 Technical requirements for high and low temperature test chamber

12.GB2423.1-1989 Low temperature test

13.GB2423.2-1989 High temperature test mode

*High-texture appearance, the body adopted an arc shape, surface matte stripes processing, and flat-handle, easy to operate, safe and reliable.

*Rectangular multi-layer glass View window, the use of guinea pigs observed in the test window witt anti-sweat heaters device prevents water gas condensate ,Knot, water droplets, PL fluorescent lamps to keep the

inside lighting.

*Door bunk isolated airtight packing, can be effectively isolated from the internal temperature of the leak

*With external water supply system, convenient to supplement the cylinder water supply, and automatic

recovery using.

*Compressor cycling system used France“Tecumseh”brand which can effectively remove condenser pipe and between capillary Lubricating oil and whole series adopt environmental protection refrigerant

(R23, R404, R507)

*Controller uses the imported LED display screen, can display measured values and setting time

*Controller with multisegment program editor and temperature and humidity can be fast (OUICK) or slope

(SLOP) controlled.

*Built-in mobile wheels allow easy movement and placed and has a strong positioning screw position.

Standard:

GB11158 GB10589-89

GB10592-89 GB/T10586-89

GB/T2423.1-2001 GB/T2423.2-2001

GB/T2423.3-93 GB/T2423.4-93

GB/T2423.22-2001 IEC60068-2-1.1990

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529