High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Model Number:

OLT-RE-15Compliance:

CE CertifiedMinimum Order Quantity:

1Mixing method:

LCD displaySpeed:

0~120minVoltage:

108V-240V 50/60HZPower:

1 yearPackaging Details:

Export wooden packageDelivery Time:

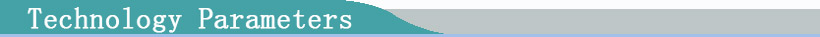

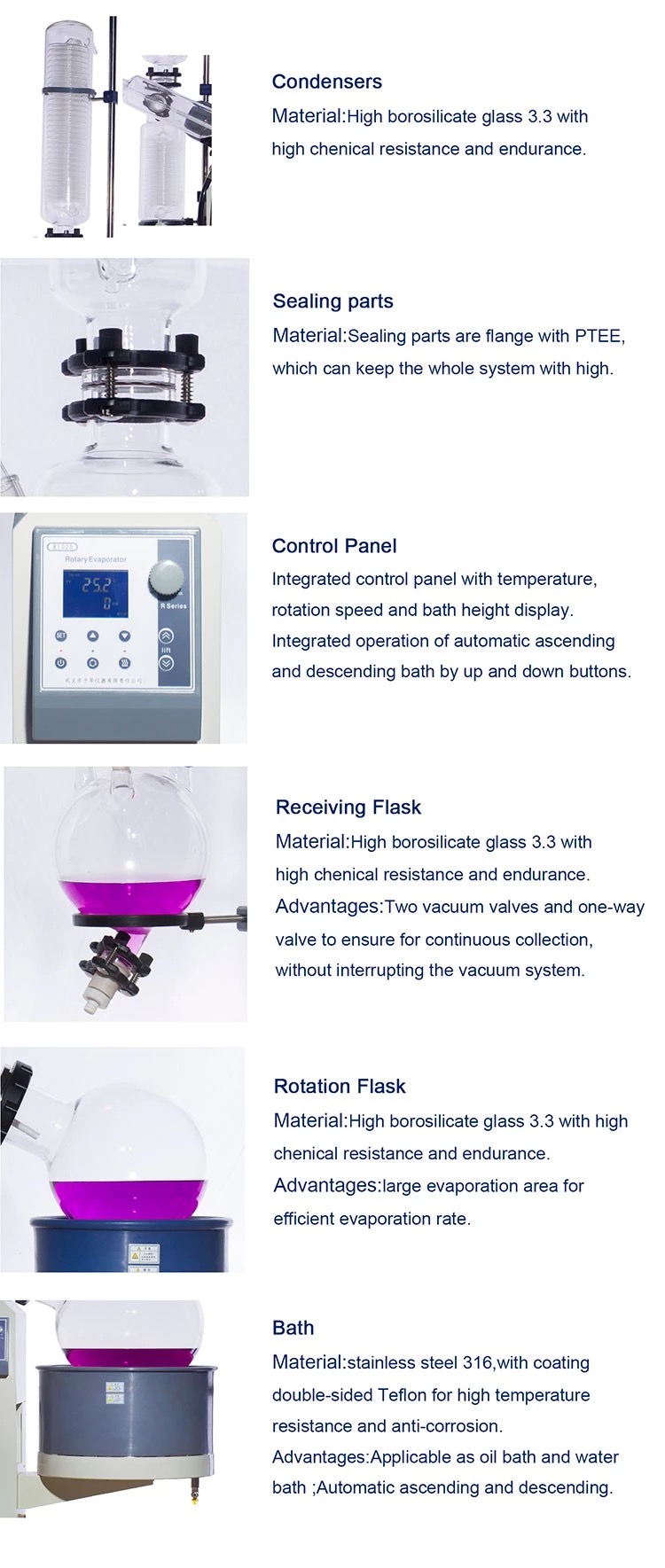

6-8 dayRotary evaporator features a specially designed motor and worm gear, which provides constant rotation at speeds from 10 to 180 rpm. As the flask containing the solvent is rotated, it continually transfers a thin layer of liquid over the entire inner surface. This gives a very large surface area for evaporation, which is caused by the gentle heating from the water bath. The rotating system is fitted with a special seal that allows the apparatus to be placed under vacuum, effectively reducing the boiling point of the solvents and removing the vapor phase, making the process much more efficient. Each unit is also equipped with an easy-to-use vacuum release and a continuous feed system, which allows solvent to be constantly drawn into the rotating flask without needing to stop the operation.

Digital water bath operates from ambient temperature to 99°C (210°F) with PID temperature control stepping at 0.1°C increments. Heating coils are located directly inside the pan for the most efficient heating possible. A built-in overheat protector will shut down power, should the controller fail.

Standard Glassware Set includes 1.32 gallon (5 liters) round-bottomed evaporating flask, 0.79 gallon (3 liters) round-bottomed receiving flask, and vertical condenser. Rotary evaporators with vertical glass condenser for are great for distillation of solvents with higher boiling points.

8.Reasonable structure,materials stress. Mechanical structure using a large number of stainless steel and aluminum alloy parts.Glass parts all with GG-17 high borosilicate glass.

Packing and Shipping

-The main parts will be wrapped with foam,then put into the carton; the mainbody portion will be packed in wooden cases;

-Both neutral and customized packaging can be available.

-We can ship the goods to you by International Express such as DHL,UPS,TNT,EMS and so on, you can also choose the appropriate one based on your timeline and budget. Besides,you can choose to use your own shipping agent

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529