High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Item NO.:

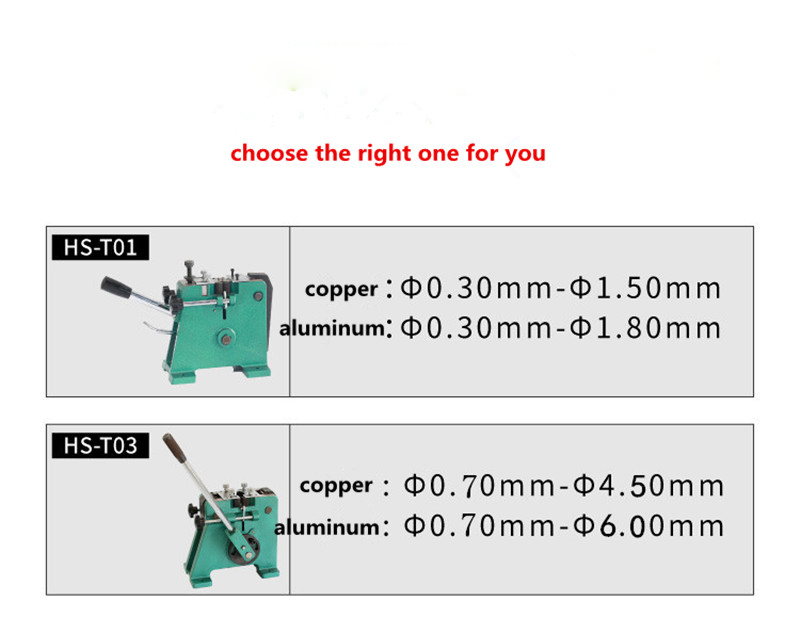

HS-T03Lead Time:

7daysShipping Port:

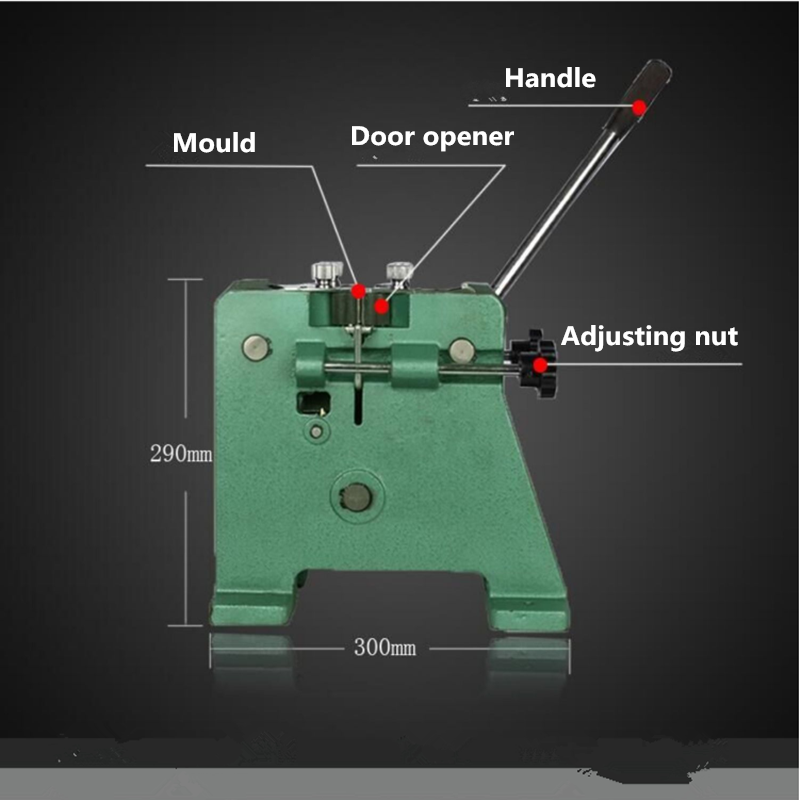

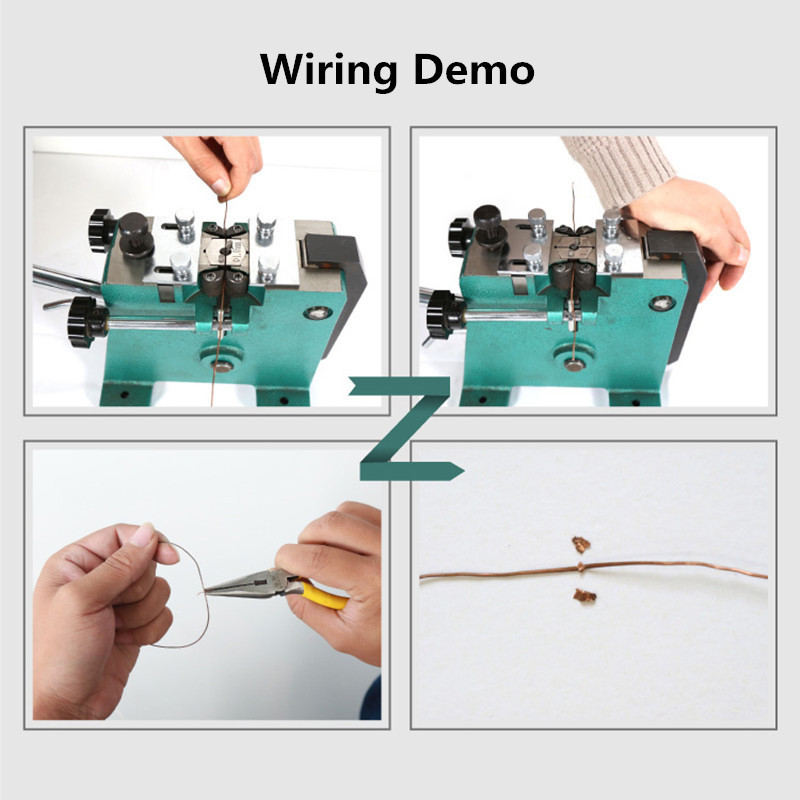

XiaMen1.the advantages of cold welder: No power supply and flux are required; the resistance and conductivity of the connector are unchanged compared with the bus bar; the copper and aluminum wire will not oxidize; the operation is portable and the deposits are easy to remove.

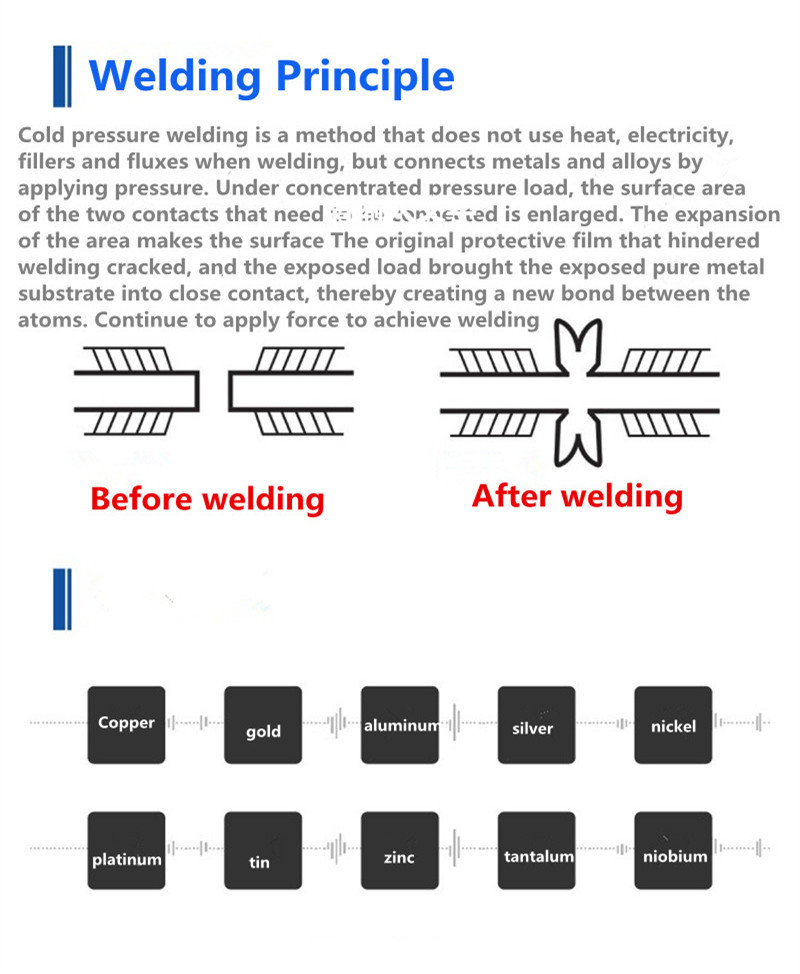

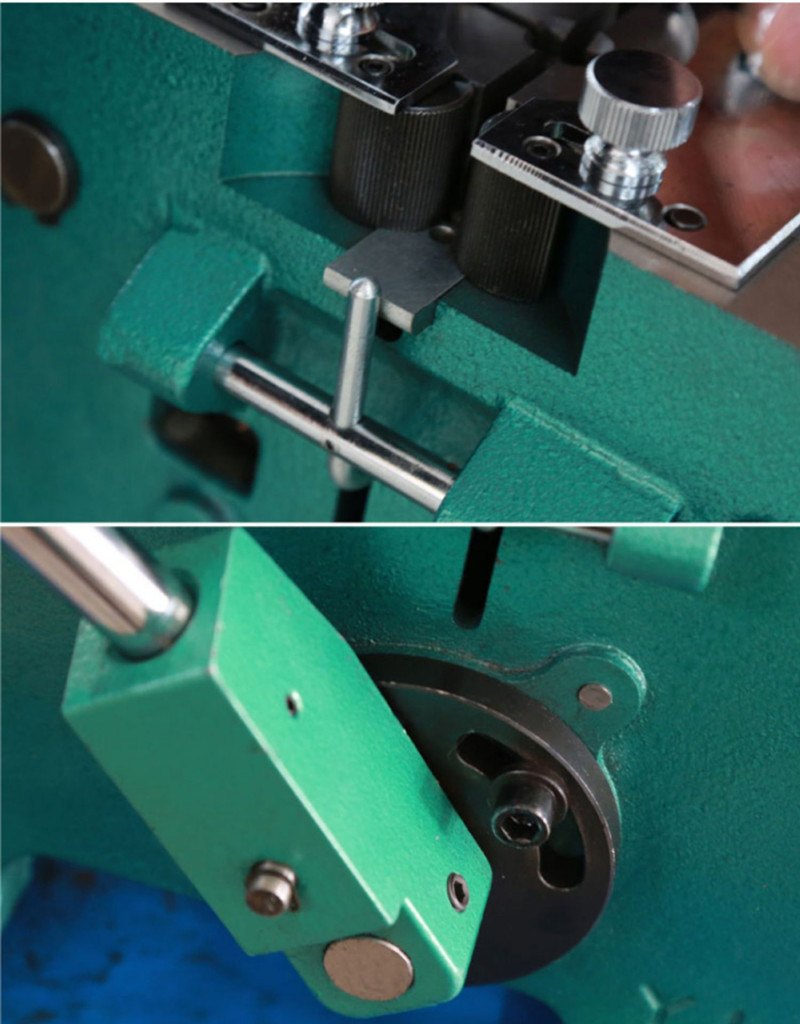

2. The welding principle of cold welding tongs: Cold pressure welding is a method of welding copper and aluminum wires and alloys by applying pressure without using electricity, heat, fillers and flux during welding. Under the action of concentrated pressure load, the surface area of the two contact surfaces that need to be connected is expanded. The expansion of the area causes the original protective film on the surface to hinder the welding to break. The bonding between atoms can continue to be welded by continuing to apply force.

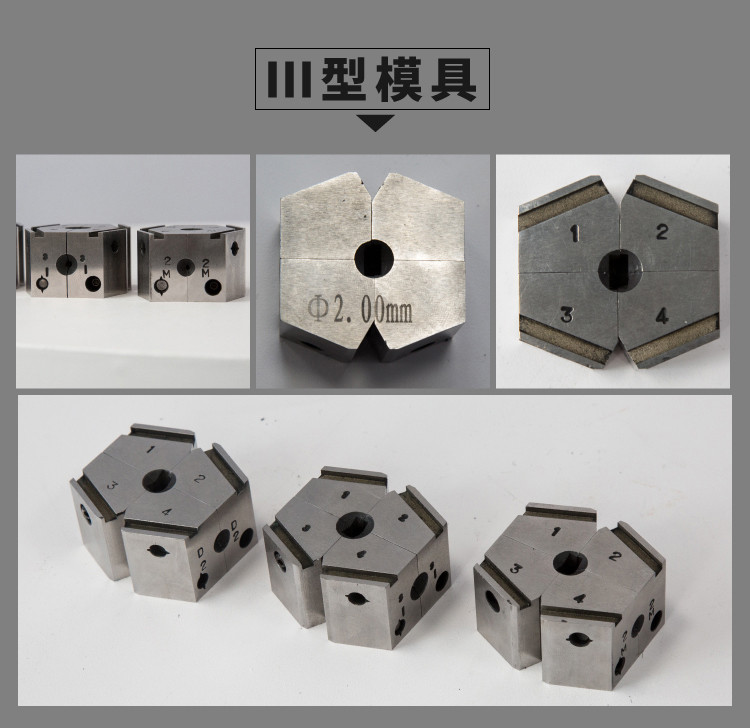

Model

HS-T03

Applicable materials

Copper Aliminum Gold Silver nickel platinum Zinc tin

Joint range for copper

φ0.8mm-φ4mm

Joint range for aluminum

φ0.8mm-φ5.5mm

Machine Weight

40KG

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529