High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

1-3 daysModel Number:

ZS-401A-120Compliance:

CE CertificationMinimum Order Quantity:

1Operation method:

ButtonWarranty:

1 year

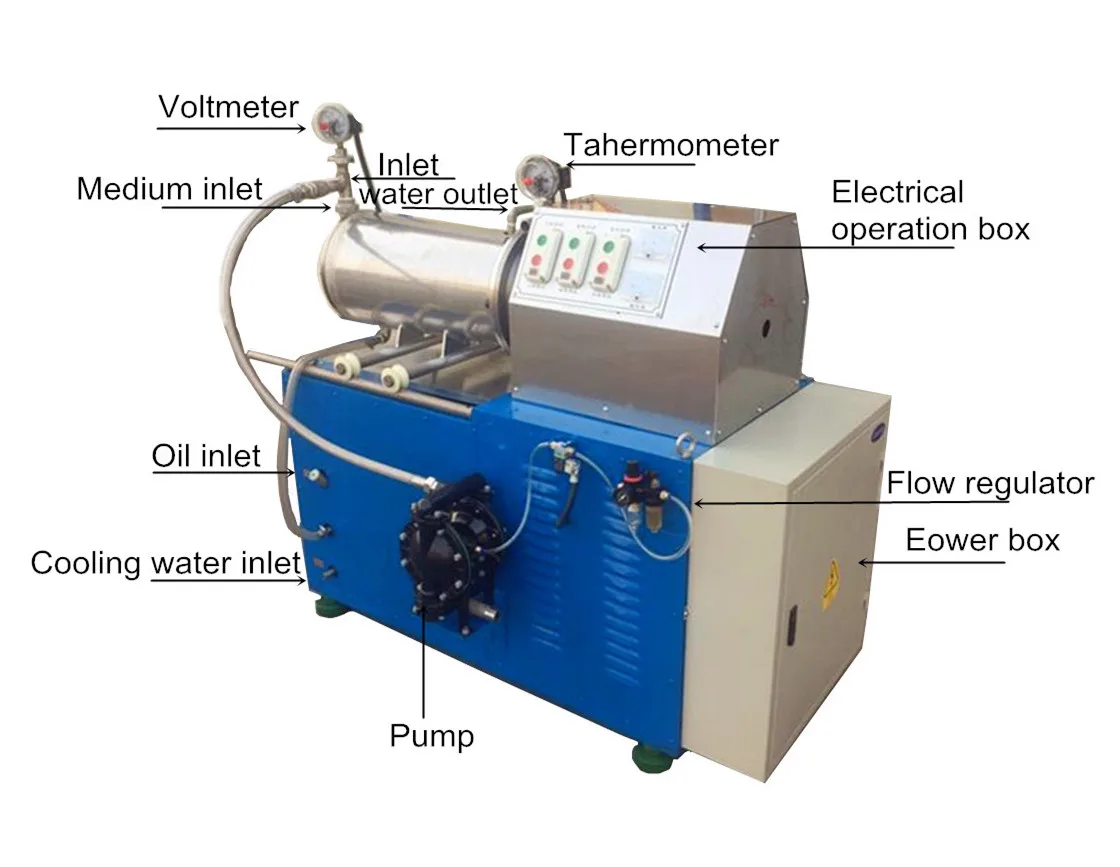

Horizontal closed conical bead mill is the powder material for solid - liquid dispersion grinding of the machinery. Widely used in coatings, dyes, inks, Light-sensitive material,medicine,food and other industries.

Horizontal sand mill design novel, compact structure,double end-face mechanical seal, the material in the closed state of production, effectively prevent the material dry, skinning and solvent evaporation, and the machine does not have a special installation basis, you can change the installation location at any time as needed.

The sander also has a dispersion and mixing effect while grinding the material.

Parameter

Model

ZS-401A-120

ZS-401B-120

ZS-401C-120

Size of roll (mm)

120X350 or customized

Heating mode

Electrical heating or oil heating

Cooling mode

Tap water cooling/oil cooling (optional)

Roller speed

Constant speed

Single speed regulator

Double frequency modulation

Motor power (Kw)

0.75X1®or customized

0.75X1® or customized

0.75X2or customized

Volume (mm)

1000X550X1200

1000X550X1200

1000X550X1200

Weight (kg)

350

370

400

Power supply

3ph, AC380V

Special models can be designed according to customers requirements

Scope of application

-- -Food: cocoa, chocolate, nut butters, sauces, mayonnaise, dressings, etc.

-- -Making paint: ink, pigment, paste, filler, dye, carbon black.

-- -Chemicals: pharmaceuticals, cosmetics, plant protectants, detergents.

-- -Minerals: kaolin (China clay), ceramic mud, fireclay.

Main Features

Detailed Image

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529