High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

3-5Product Orgin:

ChinaShipping Port:

XiamenPower:

380V/220V 50Hz 6.2kwWeight:

1600Product Description

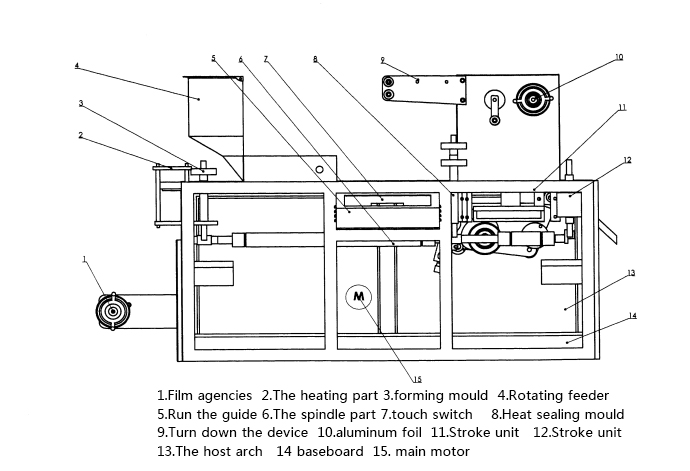

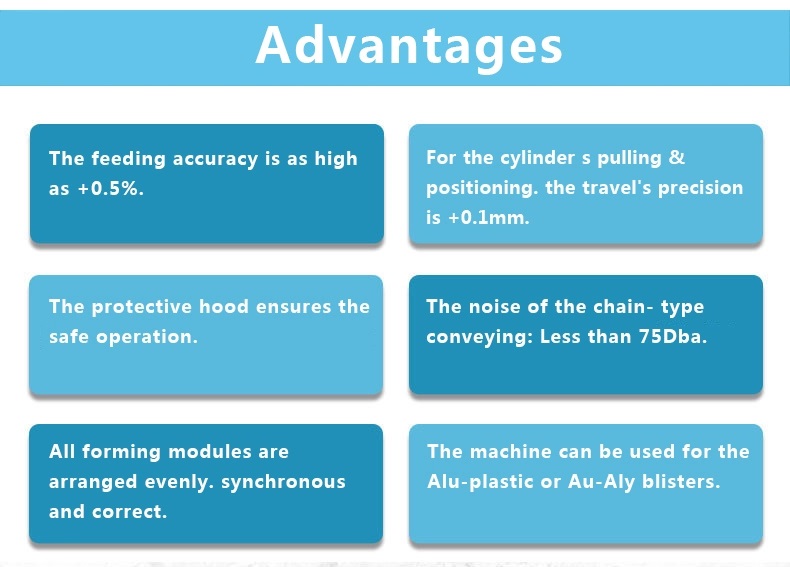

This product is a new packing machine designed by our company; it has reached domestic leading level. It is suitable for capsule, tablet, big honey pill, candy, liquid, paste, syringe as well as irregular shape Al-plastic, paper-plastic composite and Al-Al sealing packing in pharmacy, healthcare, food, cosmetics, medical equipment industry etc. This machine adopts micro-computer PLC, frequency converter, touch panel operation, high automation; it is an ideal blister packing equipment. The product passed the provincial science and technology appraisal.

Feature

Product Paramater

Model

DPP-250

Cutting Frequency (Times/min)

6-50

Production Capacity(pcs/h)

35000-230000

Max. Forming Areas And Depth (mm)

240×150×26 (standard 240×150×14)

Travel Range (mm)

40-160 (Can be lengthened to 180mm as user's requirements)

Standard Plate (mm)

80×57 (Can be manufactured as user's requirements)

Air Pressure (Mpa)

0.4-0.6

Air Supply

≥0.3m3/min

Total Power

380V/220V 50Hz 6.2kw

Main Motor Power (kw)

1.5

PVC Sheet (mm)

0.15-0.5×250

PTP Aluminum Foil (mm)

0.02-0.035×250

Dialysis Paper (mm)

50-100g×250

Mould Cooling

Tap Water Or Circulating Water

Overall Dimensions (mm)

3000×730×1600 (L×W×H)

Weight (kg)

1600

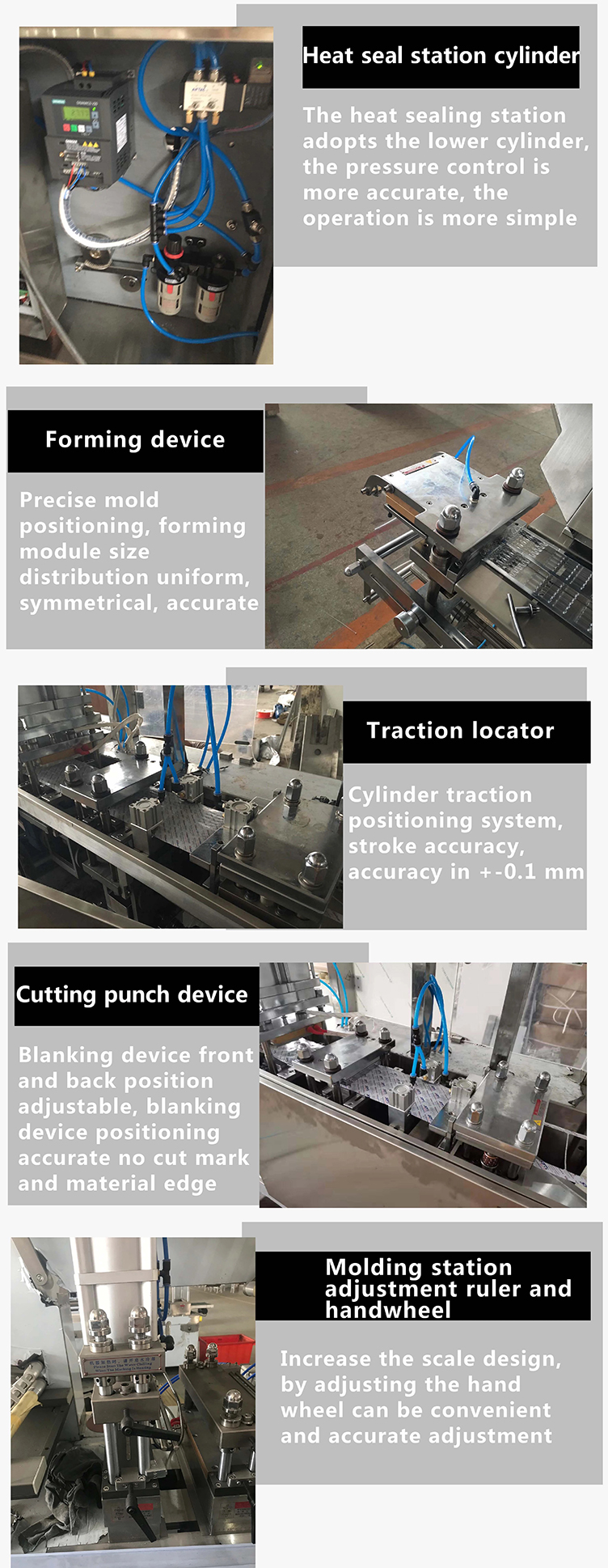

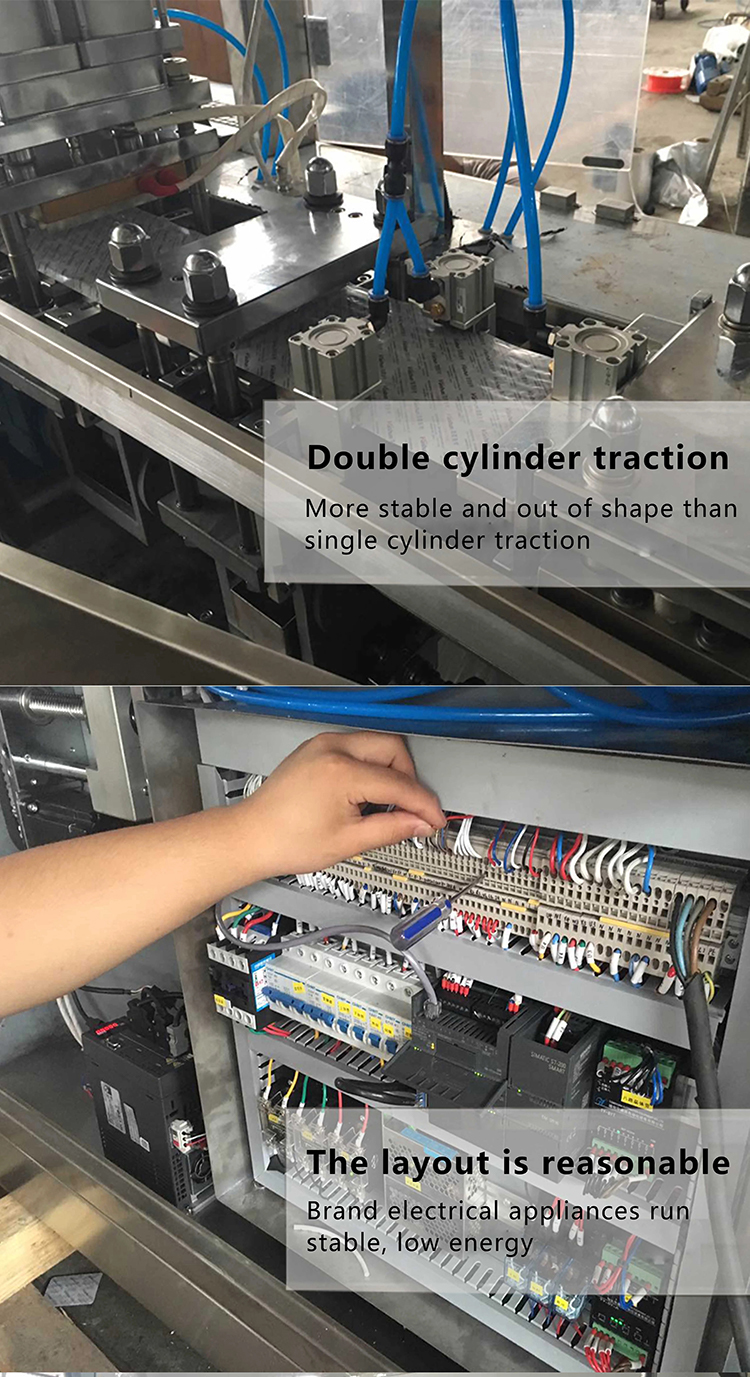

Product Details

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529