High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Model Number:

FDLS-10LMinimum Order Quantity:

1Voltage:

AC108V~240VCapacity:

10LUse pressure:

22MpaService temperature:

350℃Lead Time:

6-8dayWarranty:

One YearPackaging Details:

Standard export wooden boxStainless steel high pressure reactor is an stirring reactor for chemical material reactor with different phase, such as, gas-liquid, liquid-liquid, liquid-solid, or gas-liquid-solid, etc. It can stir all kinds of chemical material in high temperature, high pressure, vacuum condition to enhance the mass transfer and heat transfer process.

v Compact structure, high pressure flange design;

v Kettle cover and kettle body lifting and separation;

v Reactor built-in condensing coil;

v Rapid cooling after reaction;

v With bottom tube sampling function;

v LCD true color full touch operation interface;

v High torque magnetic coupling stirring;

v One-piece casting heater, high heat uniformity and fast heat transfer;

v Supports heat preservation timing and start timing, dual timing mode;

v Support pressure digital display function, free switching of multiple pressure units;

v With safety interlock function, over-temperature and over-pressure alarm;

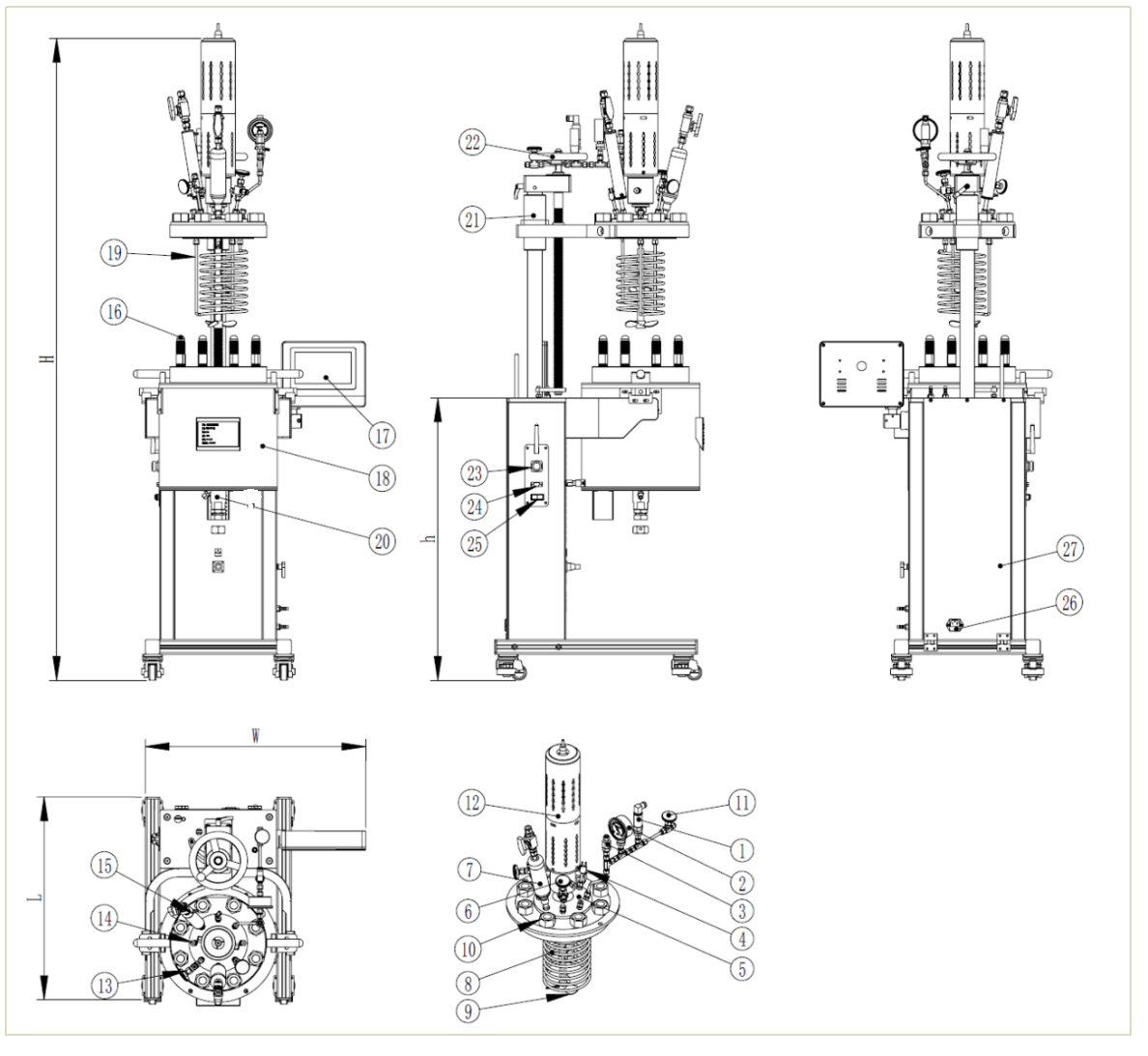

| component | illustrate | component | illustrate | ||

| 1 | Pressure Sensors | Pressure digital display | 14 | Cooling port | Cooling water inlet and outlet |

| 2 | Pressure gauge | Pressure measurement | 15 | Condenser | Condensation reflux pipe |

| 3 | Safety valve | Safety Blasting | 16 | Bolt | Pre-tightening seal |

| 4 | Temperature Sensor | Temperature measurement | 17 | Operation screen | Temperature, pressure, stirring display operation, parameter setting |

| 5 | Kettle cover | Kettle cover | 18 | Heating furnace | High temperature heating |

| 6 | Liquid Phase | Liquid Phase Valve | 19 | Cooling coil | Cooling |

| 7 | Constant pressure feeding tank | Constant pressure feeding, process feeding (optional) | 20 | Foot valve | Bottom discharge |

| 8 | Cooling coil | Cooling | 21 | Lifting module | Lift |

| 9 | Paddle | Stirring blade | 22 | Handwheel | Handwheel transmission |

| 10 | Nuts | Pre-tightening seal | 23 | Network port | Spare |

| 11 | Exhaust valve | Intake and exhaust | 24 | RS485 | Communication |

| 12 | Magnetic coupling | Magnetic coupling stirring | 25 | Switch | Power switch |

| 13 | Intake valve | Intake valve |

Packaging:

-The glass parts will be wrapped with foam,then put into the carton; the mainbody portion will be packed in wooden cases;

-Both neutral and customized packaging can be available.

Shipping:

-We can ship the goods to you by International Express such as DHL,UPS,TNT,EMS and so on, you can also choose the appropriate one based on your timeline and budget. Besides,you can choose to use your own shipping agent.

| Shipping method | Note |

|

Express |

Door to door, very convenient, don't need to clearance or pick-up |

| By air |

Airport to airport, you need to do the customs clearance and pick up the goods at your local airport, which you can have a local shipping agent to do for you. |

| By sea |

Port to port and you need to do the customs clearance and pick-up the goods

at your local port, which you can have a local shipping agent to do for you. |

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529