High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Product Orgin:

ChinaShipping Port:

XiamenModel Number:

JXF-4Minimum Order Quantity:

1Voltage:

220/240/380 Volt 50/60 HzWarranty:

1 Year

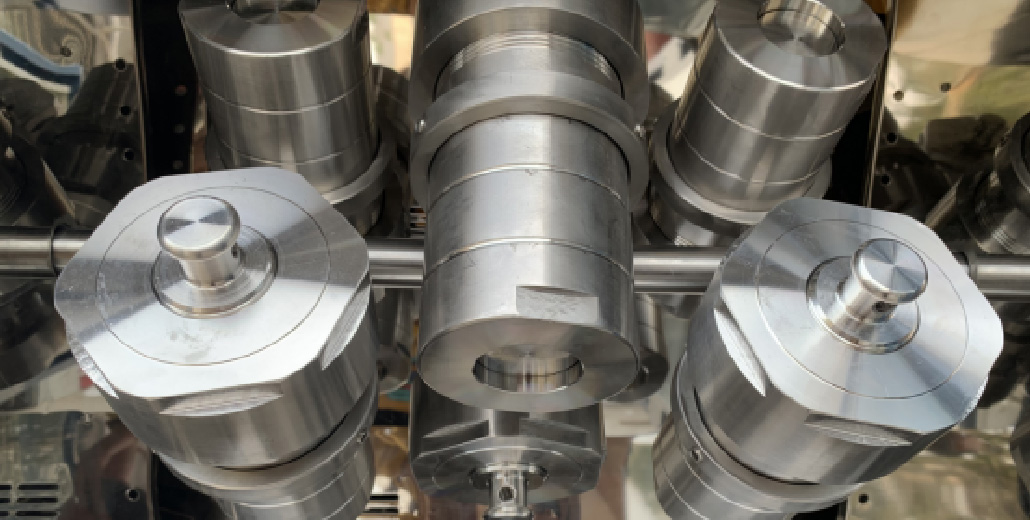

Ambient temperature: 5°C to 35°C, humidity: ≤85% RH. The supporting clamp ring of the homogeneous reactor can simultaneously meet the filling requirements of 200ml and 100ml hydrothermal synthesis reactors. The hydrothermal reactors are divided into the following specifications according to the volume: 25ML, 50ML, 100ML, 150ML, 200ML, 250ML, 500ML, 1000ML, etc. The reactor volume and working pressure can be designed and manufactured according to user requirements.

|

Hydrothermal synthesis reactor: KH-100ml or customized |

|

|

Hydrothermal synthesis reactors: High-pressure digestion vessels used in ovens, also known as sample dissolvers, pressure dissolution bombs, hydrothermal synthesis reactors, digestion vessels, and PTFE high-pressure vessels, utilize a sealed, high-temperature, high-pressure, and strong acid or alkali environment within the vessel to rapidly digest insoluble substances. They are an effective tool for sample digestion when determining trace and micronutrients. They are also suitable for sample pretreatment and digestion of heavy metals, pesticide residues, food, sludge, rare earth elements, aquatic products, and organic matter. They operate at a safe temperature of 230°C and a maximum pressure of 3 MPa. These reactors are precision-machined from high-quality 314 stainless steel and feature a PTFE liner for double-layer protection, ensuring acid and alkali resistance. With their attractive appearance, rational structure, easy operation, and excellent corrosion resistance, they are ideal for sample digestion in university laboratories, environmental monitoring, sanitation and epidemic prevention, quality control, and other scientific research fields. Our company can custom-manufacture and modify glass reactors of various sizes and sizes according to user needs! |

|

|

Technical Parameters |

1. Model: KH-100ml |

|

2. Volume: 100ml |

|

|

3. Housing Material: 304 Stainless Steel |

|

|

4. Liner Material: PTFE Liner |

|

|

5. Operating Temperature: Room Temperature - 230°C |

|

|

6. Pressure: 3MPa |

|

|

How to operate |

1. Pour the reactants into the reactor, ensuring the loading factor is less than 0.8. |

|

2. If the reactants are corrosive, place them in a PTFE liner to protect the reactor from corrosion. |

|

|

3. Place the HZ hydrothermal synthesis reactor in the heater and heat it to the desired reaction temperature (less than the specified safe operating temperature) at the specified heating rate. |

|

|

4. After the reaction is complete, cool it down strictly according to the specified cooling rate to ensure safety and extend the life of the reactor. |

|

|

5. Only open the reactor lid and proceed with subsequent operations after confirming that the internal temperature is below the boiling point of the solvent used in the reactants. |

|

|

6. Clean the hydrothermal synthesis reactor promptly after each use to prevent rust. |

|

|

7. Ensure the seals on the reactor body and lid are clean and protected from damage. |

|

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529