High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

1-3 daysModel Number:

OLT-45Minimum Order Quantity:

1Voltage:

380V 3-phase 50HzWarranty:

1 yearThis mini type PE film blowing machine, its extruder, cylinder and screw are made of quality alloy steel that have been nitrized and processed in a precision way. Hence it is sound in hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps increase the production capacity. It is applied to blow the plastic films like low density polythene (LDPE), high density polythene (HDPE) and linear low density polythene (LLDPE). It is widely applied to produce the packing bags for foodstuff, clothing, rubbish bag and vest ones.

Parameter

Model

OLT-45

OLT-50

OLT-55

Film Folding Width

100-450mm

100-600mm

200-800mm

Film Single-face Thickness

0.01-0.12mm

0.01-0.12mm

0.01-0.12mm

Screw Diameter

Φ50

Φ50

Φ50

Screw L/D Ratio

28:1

28:1

28:1

Die Size

Φ50, Φ100

Φ50, Φ100

Φ80, Φ100

Max. Extrusion Output

35kg/hr

40kg/hr

45kg/hr

Main Motor Power

11kw

11kw

11kw

Traction Motor Power

0.75kw

0.75kw

0.75kw

Total Power

20kw

20kw

22kw

Winding Torque Motor

5N.m

5N.m

5N.m

Single-winder Type

Surface Friction Type

Air Ring

1

Machine Weight

1000kg

1200kg

1400kg

Overall Dimension

2.14×1.6×2.3m

2.14×1.7×2.3m

2.14×1.8×2.3m

Working Voltage

380V 3-phase 50Hz

1) Auto Loader

2) Quick Screen Changer

3) Film Surface Treater (Digital Corona Treatment)

4) Air Compressor

5) Rotary Die Device

Detailed Image

Working principle

The program-controlled laboratory blown film extruder blown film means that the plastic melt is continuously extruded through the die under a certain temperature and a certain shearing force, and is inflated by compressed air, air ring cooling and frequency conversion traction. The process of obtaining a bi-fold plastic film. This machine is mainly used to detect the blown film feasibility of polymer materials and the gel condition in the material, as well as the dispersion of colored dispersion, control mixture and extrudate.

1) Application: PE, modified PP, modified PET, and other plastic materials which could be blown;

2) New material formula development;

3) Film blowing property test;

4) Master batch color dispersion test;

5) Optimization of blown film production technology;

6) Production of simple layer tubular film blowing.

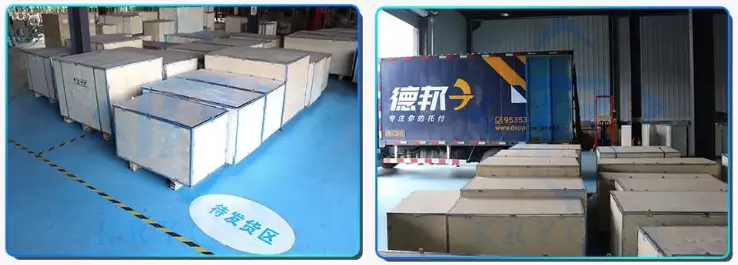

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529