High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

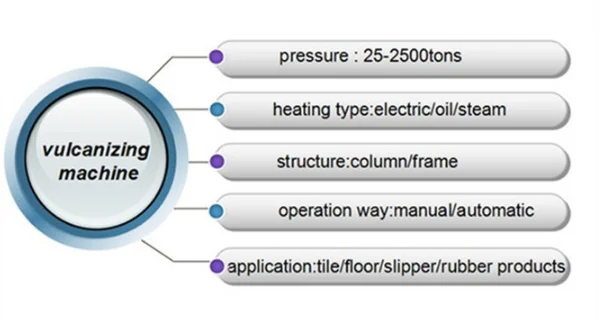

This Professional Belt Curing Press/Tire Curing Press/Flat Vulcanizing Machine for use in pressing all kinds of rubber molding products and non-model products, major equipment, can also be used to suppress various types of thermosetting plastics and foam rubber products. Independent institutions and the electrical power system that uses centralized control buttons.

Working pressure,heating temperature can be adjusted within a certain range. There are manual and

semi-automatic models .

Applicable industry

This Professional Belt Curing Press/Tire Curing Press/Flat Vulcanizing Machine suitable for rubber,

tire, recycled rubber manufacturers

Technical parameter

| Model | Unit |

50T |

63T |

|

Nominal clamping force |

KN |

500 |

630 |

|

Hot plate specifications |

mm |

400×400 |

500×500 |

|

Working layer |

layer |

2 |

2 |

|

Maximum fluid pressure |

Mpa |

16 |

20 |

|

Plunger diameter |

mm |

200 |

200 |

|

Plunger stroke |

mm |

250 |

250 |

|

Heating |

Electric heating, steam heating, oil heating |

||

|

Motor Power |

KW |

2.6 |

2.6 |

Machine features

Professional Belt Curing Press/Tire Curing Press/Flat Vulcanizing Machine

• Adopts digital time relay for automatic mould clamping, timing alarm function. It can auto-stop, auto-exhaust, automatic timing, automatic fill pressure and automatic opening function, which can effectively pretect the fulfur and the suppression of products quality.

•Electric heating time using digital temperature controller with proportional control box display ammeter

hot plate temperature and the working conditions of the heating element. With temperature control and high precision, intuitive display, easy adjustment. Steam heating with stainless steel metal hoses, reliable performance and durability.

•The hydraulic system uses a combination of double linkage pumps, both to improve efficiency and save energy. Low demand for oil, less failure, less noise.

•With automatic bleed function, and deflation and deflation time frequency adjustable

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529