High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

1-3 daysModel Number:

OLT-D350X350Minimum Order Quantity:

1Operation method:

ButtonWarranty:

1 yearColumn type platen vulcanizing press is used for vulcanizing various kinds of rubber and plastic mould products as well as non-mould products. And it can make tyre, O-rings, rubber floor tiles, slippers and other rubber products.

1) Our plate vulcanizing press machine has 4-columns structure and frame structure, as a below pressing type(upwards), the heating plate opens by the self-weight of the hot plate, platform and plunger.

2) The plate size, piston stroke and total pressure can be adjusted according to customers, actual requirement, the machine can equip with manual-pull mold and automatic hydraulic-pull mold, which reduces labors, working strength and inconvenience.

3) This machine has three kinds of control method: manually, semi-auto and full auto.

4) Fast speed mould-closing, high production efficiency, low locking speed to protect mould.

5) Made of nodular cast iron, the oil cylinder of machine is improved in compressive strength and wear resistance.

6) Adopting tubular electric-heating component to heat up, the machine can reduce air pollution to keep workshop clean without boiler.

7) The rubber vulcanizing press is beautiful in shape, rational in structure, convenient in control, safe and credible as well.

Parameter

|

Model |

OLT-D350X350 |

OLT-D400X400 |

OLT-D600X600 |

OLT-D750X850 |

OLT-D900X900 |

|

Total Pressure |

0.25mn |

0.50mn |

1.00mn |

1.60mn |

2.50mn |

|

Platen Size |

350x350mm |

400x400mm |

600x600mm |

750x850mm |

900x900mm |

|

Daylight |

125mm |

125mm |

125mm |

125mm |

125mm |

|

Working Layer |

2 |

2 |

2 |

2 |

2 |

|

Piston Stroke |

250mm |

250mm |

250mm |

250mm |

250mm |

|

Heating way |

Electric |

Electric |

Electric |

Electric |

Electric |

|

Platen Unit Area Pressure |

20kg/cm² |

31kg/cm² |

28kg/cm² |

25kg/cm² |

31kg/cm² |

Detailed Image

Product Dispaly

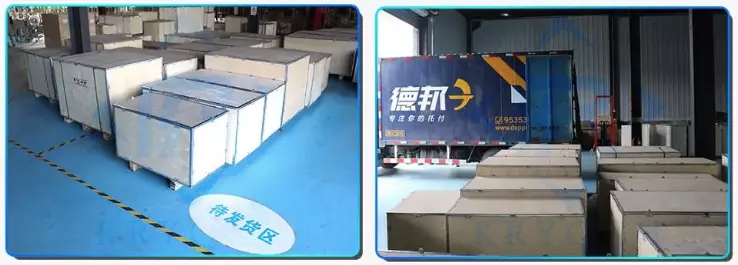

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529