High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Lead Time:

1-3 daysModel Number:

OLT-0.50MNMinimum Order Quantity:

1Operation method:

ButtonWarranty:

1 year

1. The machine has the functions of automatic button up, manual exhaust, automatic pressure compensation, automatic timing, automatic constant temperature, and manual down (pull the hand handle after the alarm).

2. Description of the main components of the host:

2.1. Column: The column is made of high-quality 45# steel, which is refined and polished after quenching and tempering treatment, which enhances the overall strength and abrasion resistance of the column.

2.2. Upper and lower bases and platforms: all made of QT500-7 ductile iron. It is finished after high temperature tempering and aging treatment to eliminate internal stress and prevent deformation.

2.3 Plunger: The plunger is made of QT500-7 ductile iron. The surface of the plunger is quenched and then finely machined. The material and manufacturing process have high surface hardness and are not easy to wear, which improves the overall service life of the plunger. Abrasion resistance.

2.4. Hot plate: The hot plate is made of Q235A high-quality carbon steel, after quenching and tempering, it is made of fine processing and grinding, with good surface finish and strong wear resistance.

2.5. Seals: The cylinder seals are made of YX high-quality polyurethane oil seals, which are resistant to oil, aging and abrasion.

2.6 Heat insulation board: The heat insulation board adopts high-quality calcium silicate board, with a pressure resistance of 3.5Mpa and a heat insulation coefficient of 0.031.

2.7. Hydraulic system: all hydraulic devices adopt national standard components in accordance with national standard requirements, easy to buy and replace, reasonable layout, and easy to maintain and repair. In addition: the hydraulic station oil tank is designed reasonably, occupies a small area, and has a small capacity.

2.8. Electrical system: This electromechanical device adopts the well-known brands of Chint and Delixi. The electrical device has small size, compact structure, fatigue resistance, and is suitable for continuous high-strength work.

Parameter

|

No |

Parameter |

OLT-0.50MN |

Remarks |

|

1 |

Nominal clamping force |

0.50MN |

50t |

|

2 |

Flat (hot plate) specifications |

400x400x60mm |

Material: Q235A high quality carbon steel |

|

3 |

Number of working layers |

layer |

|

|

4 |

Number of hot plates |

Two pieces |

|

|

5 |

Parallelism of hot plate |

≤0.15mm |

|

|

6 |

Roughness of hot plate surface |

Ra≤1.6a (2.5µm) |

|

|

7 |

way to heat up |

Electric heating |

|

|

8 |

Heating temperature |

Adjustable between room temperature and 200℃ |

|

|

9 |

Heater |

110V500Wx6 pieces/piece x2 pieces=6KW |

|

|

10 |

Temperature control method |

Digital display |

|

|

11 |

Pressure per square centimeter |

27kg/cm² |

|

|

12 |

Hot plate spacing |

250mm |

|

|

13 |

Plunger stroke/diameter |

250mm/Φ200mm |

Chilled Alloy |

|

14 |

Number of cylinders |

1 set |

Material: QT500-7 |

|

15 |

Maximum use system pressure |

16Mpa |

|

|

16 |

structure type |

Four-post |

|

|

17 |

Column diameter |

Φ50mm/4 pieces |

High quality 45# steel |

|

18 |

way to control |

Semi-automatic control |

Oil inlet in the middle |

|

19 |

Delivery date |

Spot |

50t |

|

Remarks |

The machine has the functions of automatic button up, manual exhaust, automatic pressure compensation, automatic constant temperature, adjustable temperature, vulcanization timing, time alarm, and manually pull the hand handle to control the decline. |

||

Advantage

1.double column construction

2. easy operation and repair

3.wear-resisting,corrosion resisting,high hardness and long life

Application

1.Applicable for various rubber moulding productiony

2.PLC control & touch screen

3.Auto mold closing, air exhaust, temperature control, timing setting

4.Custom mold push out system

5.Well-sealed hydraulic cylinder with precise grinding and finishing

6.Stable hydraulic pressure station

Detail Image

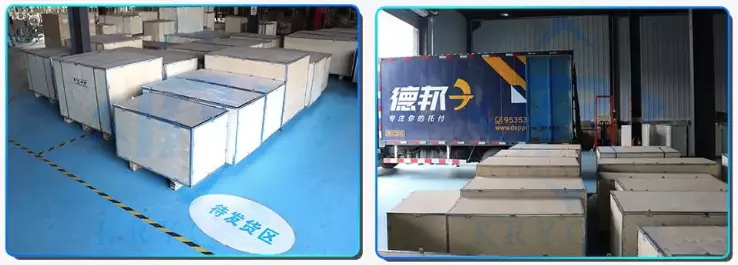

Packing & Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529