High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Product Orgin:

ChinaShipping Port:

XiamenModel Number:

OLT-HP-500Compliance:

CE CertifiedMinimum Order Quantity:

1Capacity:

500mlWarranty:

1 yearThe Magnetic Coupled Mechanical Stirring Laboratory Micro Reactor High Pressure Reactor is a state-of-the-art research-grade reactor system designed for precise and safe chemical reactions under controlled conditions. Engineered for laboratory applications, this reactor integrates magnetic coupling technology with a high-efficiency mechanical stirring system, ensuring leak-free operation, stable mixing, and long-term durability, even under high pressure and temperature.

This micro high-pressure reactor is ideal for applications in chemical synthesis, pharmaceutical R&D, material science, catalyst evaluation, and hydrogenation experiments, offering researchers a reliable platform to conduct reproducible and accurate experimental studies.

Reactor Volume: 25 mL – 500 mL (custom available)

Pressure Range: up to 20 MPa (200 bar)

Temperature Range: RT to 350°C (with heating jacket or oil bath)

Stirring Speed: 0 – 1500 rpm (adjustable)

Material of Construction: 316L Stainless Steel, Hastelloy, Titanium (optional)

Sealing Method: Magnetic coupling, leak-free

Heating Method: Electric heating jacket / oil bath circulation

Safety Devices: Pressure gauge, relief valve, rupture disc, temperature controller

|

Model

|

OLT-HP-10

|

OLT-HP-25

|

OLT-HP-50

|

OLT-HP-100

|

OLT-HP-250

|

OLT-HP-500

|

|

volume(ml)

|

10

|

25

|

50

|

100

|

250

|

500

|

|

Service temperature(℃)

|

RT-350℃,Higher temperatures can be customized according to customer requirements

|

|||||

|

Use pressure(Mpa)

|

-0.1-10 Standard 10Mpa, customized according to customer requirements

|

|||||

|

heating power(w)

|

600

|

600

|

1000

|

1000

|

1500

|

1500

|

|

control mode

|

PID artificial intelligence adjustment, LCD digital display

|

|||||

|

Mixing form

|

Magnetic coupling mechanical stirring or bottom magnetic stirring optional

|

|||||

|

Mixing power(w)

|

80

|

|||||

|

Stirring speed(rpm)

|

0-1500

|

|||||

|

Positive and reverse regulation

|

Positive inversion

|

|||||

|

Temperature setting

|

Self setting function of temperature

|

|||||

|

safety protection

|

Set upper temperature limit, over temperature alarm, self power-off protection

|

|||||

|

Timing function

|

Working time and holding time can be set regularly

|

|||||

|

Timing function supply voltage

|

AC 108V-240V 50Hz

|

|||||

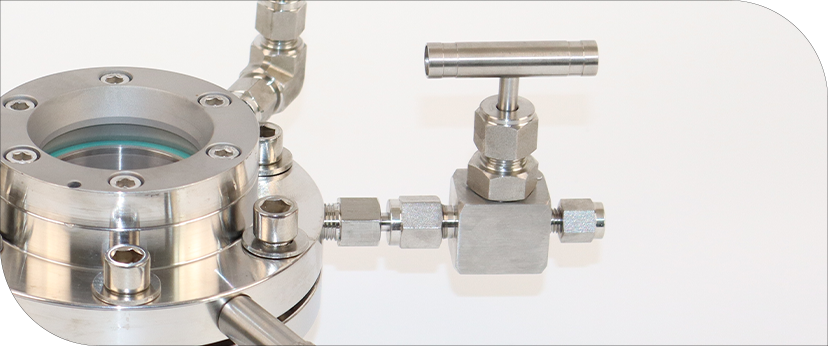

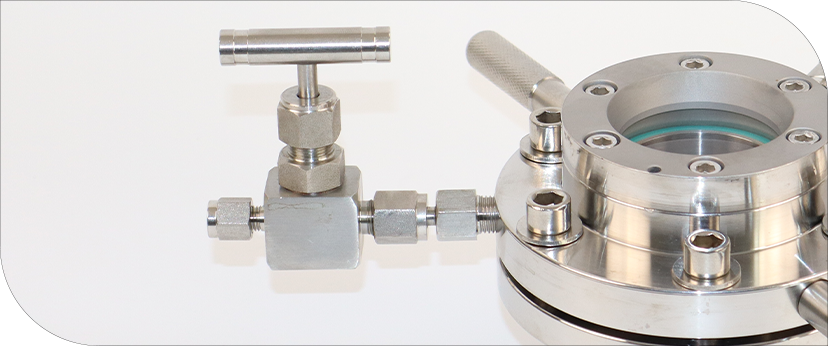

1️⃣ Aseismatic pressure gauge

Equipped with a high-quality aseismatic pressure gauge, the reactor provides accurate and stable pressure monitoring even under high vibration or rapid pressure changes. This ensures reliable operation and enhanced safety during high-pressure experiments.

2️⃣ Discharge port and Air inlet

The reactor is designed with a dedicated discharge port and air inlet, allowing easy sampling, product discharge, and gas introduction. This flexible configuration improves operational efficiency and makes the system more user-friendly for different experimental setups.

3️⃣ Feed port and Air outlet

Featuring a separate feed port and air outlet, the reactor enables continuous or batch feeding of reactants while ensuring controlled venting of gases. This design supports safer handling of volatile or pressurized reactions and provides greater process flexibility.

4️⃣ PTFE or stainless steel stirrer optional

Users can choose between a PTFE-coated stirrer for excellent chemical resistance or a stainless steel stirrer for high-strength and durability. This optional configuration ensures compatibility with a wide range of reaction media and experimental requirements.

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529