High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Model Number:

OLT-PS-10LCompliance:

CE CertifiedMinimum Order Quantity:

1Capacity:

10LVoltage:

108V-240V 50/60HZWarranty:

3 yearDimension(L*W*H):

600mm×500mm×560mmWeight:

80 kgPackaging Details:

Export wooden packageDelivery Time:

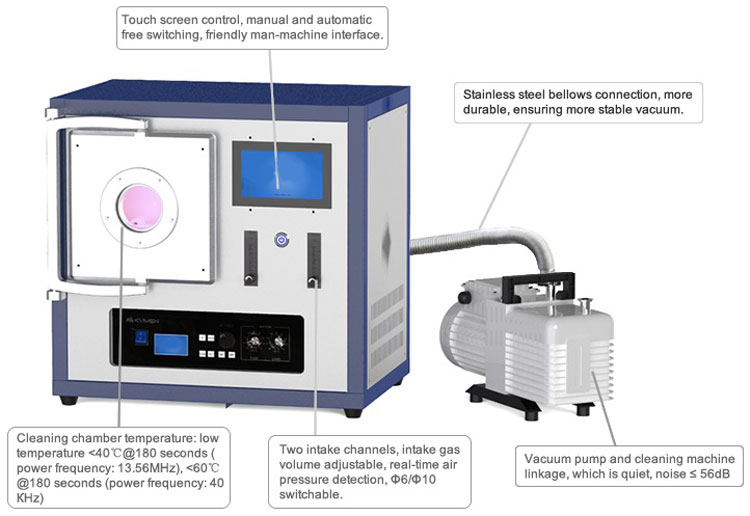

8-10 day10L plasma cleaner is equipped with a mechanical vacuum pump, while vacuuming maintains the vacuum of the chamber, the pollutants after the plasma reaction can also be pumped away by the vacuum pump; therefore, the short-time cleaning can completely clean the organic pollutants.

Model:OLT-PS-10L

Main parts

Item

Parameters

Cleaning the chamber

Chamber material

High purity quartz

Chamber size

Diameter 200 mm; Length 340 mm

RF power supply

Power supply features

The power supply is an all-solid-state RF power supply, and adopts a high-stability and high-reliability power amplifier module and a DC module, which effectively ensures the RF power output of the power supply. High quality electronic components are used to ensure the reliability of the products.

Power advantage

● Long time normal operation

● Simple and flexible operation

● High power supply efficiency and low heat generation

●With perfect reflection power protection function

RF power

0~100W continuously adjustable/0~150W continuously adjustable

Signal frequency

13.56MHz ±0.005%

Reflected power

≤100W

Power stability

±0.1%

RF connector

N type connector

Machine efficiency

≥75%

Harmonic component

≤-50 dBc

cooling method

Forced air cooling

Gas measurement

Measuring unit

Float flowmeter

Gas channel

Two channels

A channel range

10~100ml

B channel range

16~160ml

Vacuum

Vacuum measurement

Digital vacuum gauge (resistance gauge)

Vacuum pump

Two-stage rotary vane vacuum pump

Motor speed

50 Hz: 1440; 60 Hz: 1720

Pumping rate

50 Hz: 1.1L/s; 60 Hz: 1.3L/s

Vacuum range

0.1Pa~10000Pa

Ultimate vacuum

0.5Pa

Motor noise

≤56dB

Pipe interface

Gas inlet: KF16; exhaust port KF16.

Connecting pipe

KF16 vacuum bellows

Vacuum valve

Solenoid valve

Motor Power

400W

Others

Power supply

AC108V-240V 50/60Hz

Total power

550W/600W

Operating temperature

-10℃- 40℃

Working vacuum

≤40Pa

Overall size

600mm×500mm×560mm

Total Weight

80kg (including packaging)

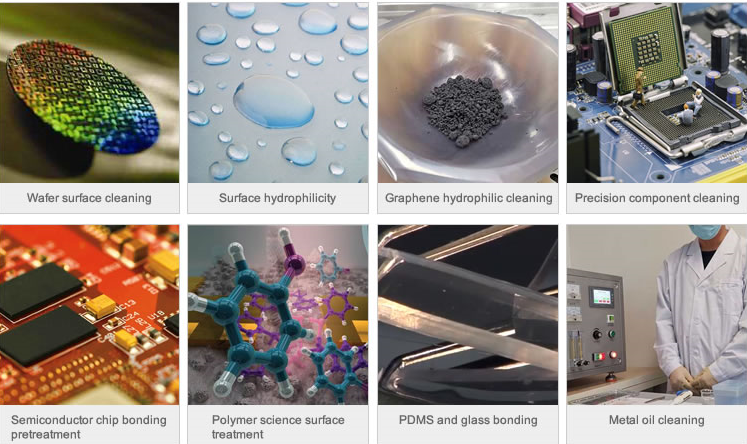

In addition to the cleaning function, this small plasma cleaner can change the surface properties of some materials according to the needs under certain conditions. During the cleaning process, the glow discharge of the small plasma cleaner not only enhances the adhesion, compatibility and wettability of these materials, but also disinfects and sterilizes the materials.

This plasma cleaner is suitable for laboratory and small-scale production. Using 13.56Mhz rf power supply, can be used to match a variety of commonly used gas plasma. There are a variety of common specifications for RF power supply from 100W to 1000W, which can meet the diverse needs of users.

Metal: remove oil, greasy dirt and other organic matter and oxide layer on the metal surface;

Automotive manufacturing: used for pre-treatment of plastics and paint spraying in automotive manufacturing processes;

Textile production: used for the hydrophilicity, hydrophobicity and surface modification of textiles, filter screens and films;

Biomedicine: Petri dishes enhance activity, vascular stents, syringes, catheters and pro-wetting of various materials, before cross-coating treatment;

Aerospace: surface coating pretreatment of insulating materials, electronic components, etc.;

Electronics: circuit board cleaning and etching. Non-oxidation and activation treatment of PP and other materials, to improve solderability;

Semiconductor industry: wafer processing and processing to remove photoresist, pre-package pretreatment;

LED: Pre-treatment before the bracket is cleaned and packaged;

Plastic rubber: Improve the surface activity of PS, PE, PTFE, TPE, POM, AS and PP, making it easy to bond and print.

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529