High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Item NO.:

GD-5Lead Time:

7daysShipping Port:

XiaMen

Product Overview

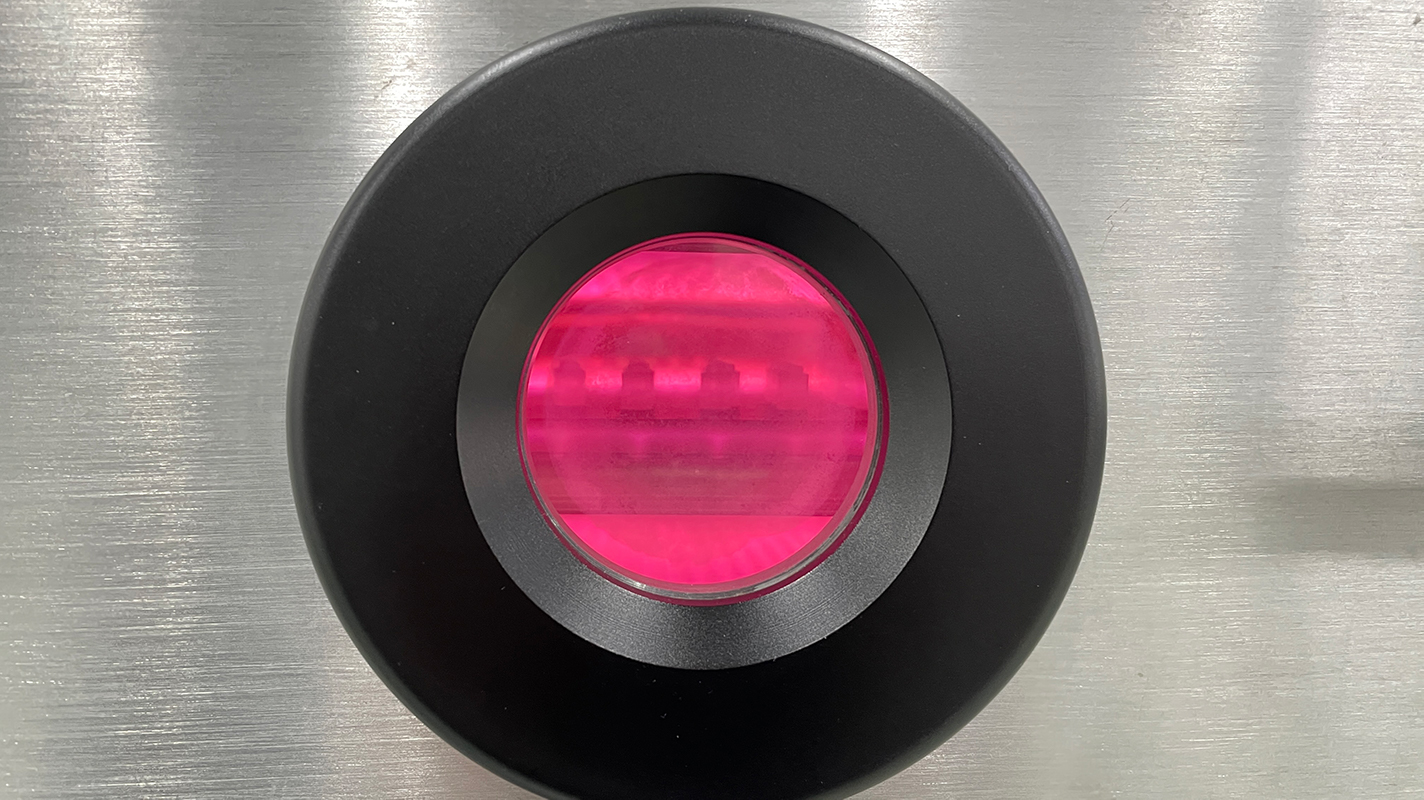

OEM Plasma Chamber Lab Oxygen Plasma Cleaner Plasma Cleaning Machine

|

No |

Item |

Data |

| 1 |

Input Voltage |

AC220 V |

| 2 |

Output Power |

100-300 W |

| 3 |

Frequency |

40 kHz / 13.56 MHz |

| 4 |

Cavity Volume |

5 L |

| 5 |

Cavity Size |

Φ150 mm*280 (D) mm |

| 6 |

Size |

550(L)mm*560(W)mm*400(H)mm |

| 7 |

Cavity Material |

316 stainless steel / aluminum alloy |

| 8 |

Weight |

45 kg |

| 9 |

Gas Used |

Air、N2、O2、Ar(optional) |

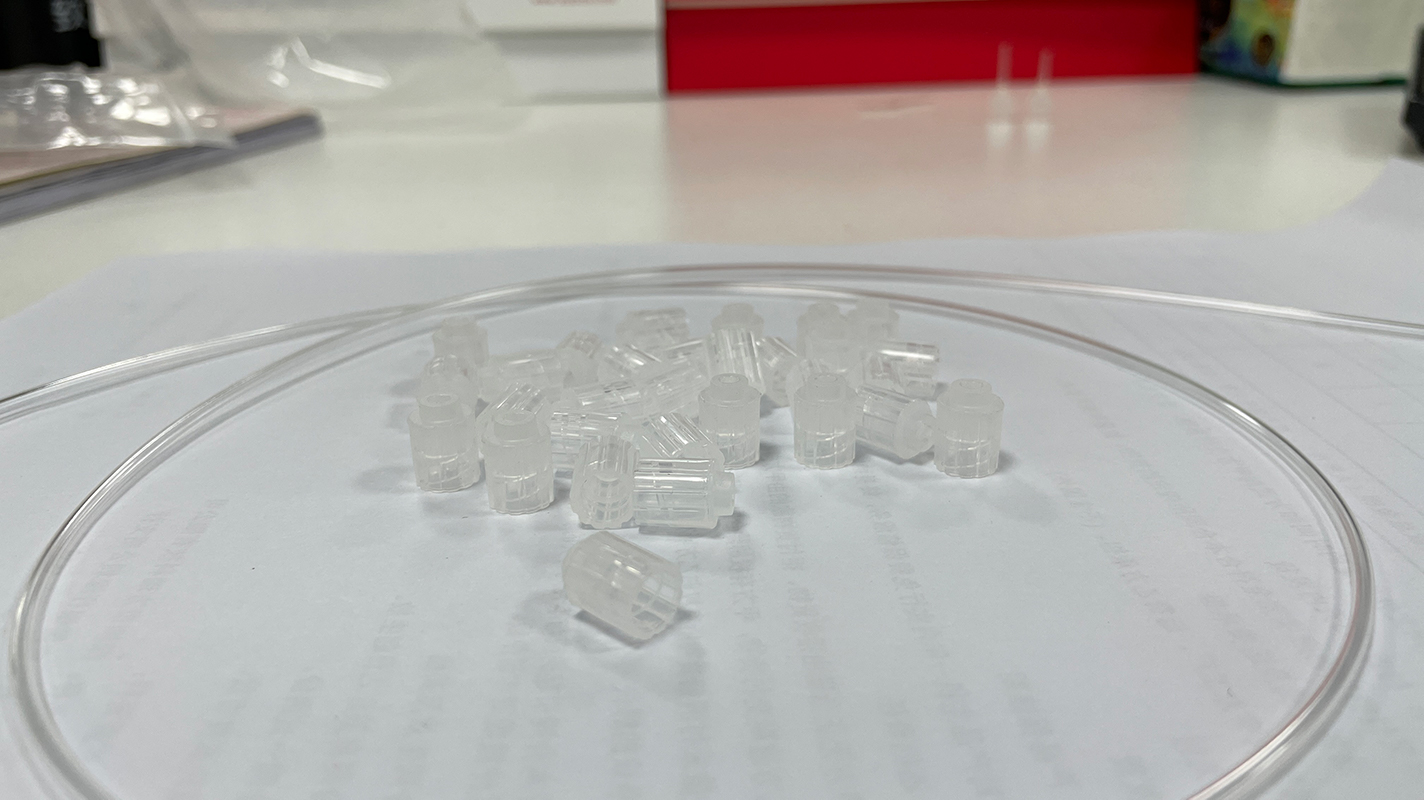

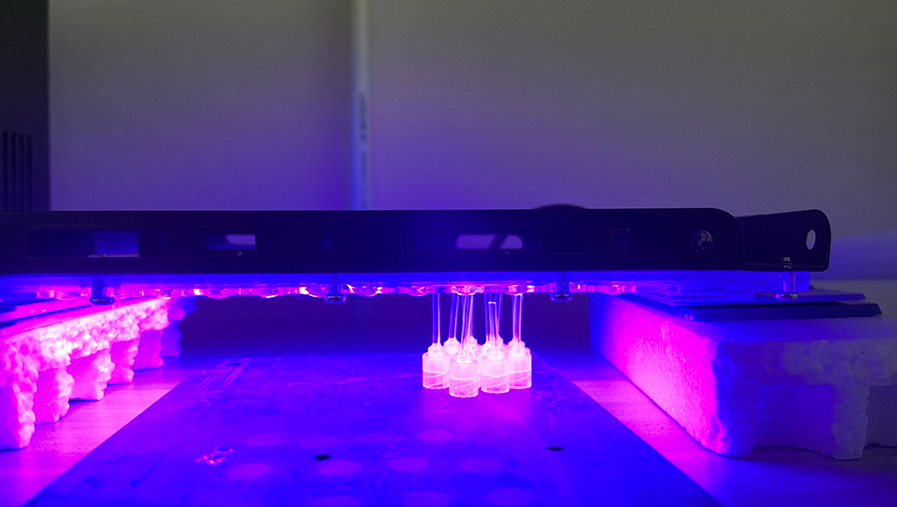

Plasma cleaning machine can improve bonding strength between PMMA and TPE material. The material of PMMA and TPE is non-polar, it can’t be stick to each other even with glue.After plasma treated , material surface is modified and become polar material. At this situation, they can bond with each other by epoxy glue. In order to reach success bonding ,UV curing is necessary.

UV glue contains a light curing agent, which is a kind of light-curing agent that can absorb a certain wavelength of energy in the ultraviolet region (250-420 nm) or visible light region (400-800 nm) to generate free radicals, cations, etc., thus triggering the polymerization of monomers. A co-curing compound that transforms the adhesive from a liquid to a solid in seconds. After plasma treatment and UV curing some seconds , the pull value can be reach ≥35 N. Before no plasma treatment , the pull value is weak and they can pull away easily.

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529